目录

切换1.What is PVC (PolyVinyl Chloride)?

Polyvinyl Chloride (PVC) is an economical and versatile thermoplastic polymer. It is widely used in applications such as pipes, medical devices, and wire & cable insulation. PVC is a white, brittle solid available in powder or granular form, is increasingly being used in place of traditional building materials like wood, metal, concrete, rubber, and ceramics across various applications. This shift is largely due to PVC’s versatile properties, including its lightweight nature, durability, cost-effectiveness, and ease of processing.

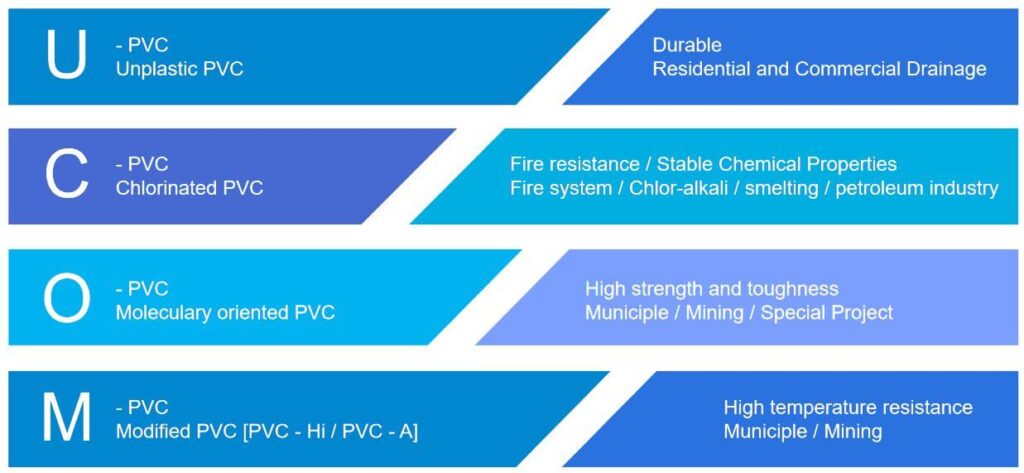

Polyvinyl Chloride (PVC) is available in various forms, each with distinct properties tailored for specific applications. The two primary categories are Flexible and Rigid PVC, but there are also specialized variants like CPVC, PVC-O, and PVC-M.

*According to WKIPEDIA

1.1 Flexible PVC (Plasticized PVC or PVC-P)

Flexible PVC is created by adding plasticizers to standard PVC, which reduce crystallinity and increase flexibility. These plasticizers act as lubricants, making the material clearer and more pliable. Flexible PVC is commonly used in applications where flexibility is essential, such as in cables, flooring, and inflatable products.

1.2 Rigid PVC (Unplasticized PVC or UPVC)

Rigid PVC, also known as UPVC or PVC-U, is a stiff, cost-effective material that offers high resistance to impact, water, weather, chemicals, and corrosive environments. This makes it ideal for construction applications, including pipes, window frames, and roofing materials.

1.3 Chlorinated Polyvinyl Chloride (CPVC)

CPVC is produced by chlorinating PVC resin, which increases its chlorine content. This modification enhances the material’s durability, chemical stability, and flame retardancy. CPVC can withstand higher temperatures compared to standard PVC, making it suitable for hot water pipes and industrial fluid handling.

1.4 Molecular Oriented PVC (PVC-O)

PVC-O is created by reorganizing the amorphous structure of UPVC into a layered configuration through a process known as bi-axial orientation. This enhances the material’s physical properties, such as stiffness, fatigue resistance, and impact strength, while reducing its weight. PVC-O is often used in pressure pipes and other demanding applications where high performance is required.

1.5 Modified PVC (PVC-M)

PVC-M is an alloy formed by adding modifying agents to standard PVC. These agents improve the material’s toughness and impact resistance, making it suitable for applications where enhanced durability is necessary, such as in underground pipes and heavy-duty industrial products.

2. What are the key advantages of PVC?

2.1 Electrical Insulation

PVC is recognized for its excellent electrical insulation properties, making it an ideal material for applications in electrical wiring and cables. Its high dielectric strength allows it to effectively resist electrical currents, ensuring safety and reliability in electrical installations.

2.2 Durability and Longevity

One of the standout features of PVC is its exceptional durability. It is highly resistant to various forms of environmental degradation, including weathering, chemical corrosion, and physical impact. This makes PVC a top choice for products that are expected to endure harsh outdoor conditions and have a long service life. Its ability to resist shock and abrasion further enhances its suitability for a wide range of demanding applications.

2.3 Flame Retardancy

PVC’s inherent flame-retardant properties are attributed to its high chlorine content. This composition makes PVC self-extinguishing; once the source of ignition is removed, PVC stops burning. Its high oxidation index (≥45) indicates that it requires a higher concentration of oxygen to sustain combustion. When combined with additives like antimony trioxide and phosphate ester plasticizers, PVC exhibits enhanced fire performance and retains its mechanical integrity even under high temperatures.

2.4 Cost-Effective Performance

PVC offers an impressive balance of cost and performance. It is an economical material with robust physical and mechanical properties, providing a long-lasting solution at a lower cost compared to many other materials. The low maintenance requirements of PVC further contribute to its cost-efficiency, making it a preferred choice for both large-scale industrial applications and everyday consumer products.

2.5 Mechanical Strength

PVC is known for its mechanical robustness. It is lightweight yet tough, capable of withstanding significant wear and tear without losing its structural integrity. Its resistance to abrasion makes it suitable for applications where mechanical stress is a concern.

2.6 Chemical Resistance

PVC exhibits strong resistance to a wide range of chemicals, particularly inorganic compounds. It can withstand exposure to diluted acids and alkalis as well as aliphatic hydrocarbons, making it suitable for use in environments where chemical exposure is likely.

However, certain grades of PVC may be vulnerable to attack by specific organic solvents such as ketones, esters, chlorinated hydrocarbons, aromatic hydrocarbons, aromatic ethers, amines, and nitro-compounds. This necessitates careful consideration of the chemical environment when selecting PVC for specific applications.

3. What are differences between PVC and UPVC?

| 特征 | Unplasticized or Rigid PVC UPVC | Plasticized or Flexible PVC PVC |

|---|---|---|

| Composition | Contains no added plasticizers | Contains plasticizers |

| Density | 1.3-1.45 g/cm³ | 1.1-1.35 g/cm³ |

| Temperature Range | Softening temperature range of 65–100°C | Maximum operating temperature 60 °C |

| Yield Strength psi / MPa 灵活性 |

4,500–8,700 (31–60 MPa) Rigid, not flexible |

1,450–3,600 (10.0–24.8 MPa) 灵活的 |

| Weather Resistance | Excellent, resists UV and weathering | Moderate; may degrade faster in UV exposure |

| Chemical Resistance | High resistance to chemicals and corrosive environments | Good, but generally lower than UPVC |

| Environmental Impact | Recyclable, longer lifespan reduces need for replacement | Recyclable, but plasticizers may pose environmental concerns |

| Thermal Properties | Higher thermal resistance compared to PVC-P | Lower thermal resistance, may soften at higher temperatures |

| Flame Retardancy | Self-extinguishing | Self-extinguishing |

| Durability | Extremely durable, long-lasting in harsh environments | Less durable, more prone to wear and tear over time |

| Applications | Pipes, electrical conduit, window frames, doors, siding, plumbing | Cable insulation, hoses, flooring, inflatable products |

4. How Do additives Influence the Flexibility and Durability of PVC?

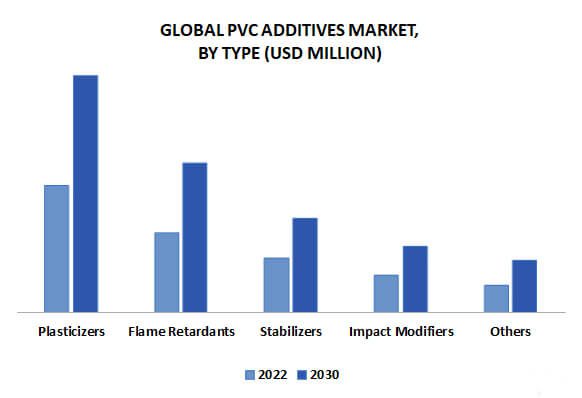

4.1 Plasticizers

Plasticizers are typically esters of phthalic acid, such as diisononyl phthalate (DINP) or diisodecyl phthalate (DIDP). These additives intercalate between the polymer chains of PVC, reducing intermolecular forces and increasing the free volume within the material. This results in a more flexible, softer material that can bend without cracking. Plasticizers can also lower the processing temperature, making PVC easier to mold and shape.

While plasticizers enhance flexibility, they can also migrate out of the PVC over time, leading to the material becoming brittle. But this migration can also lead to environmental concerns.

4.2 Stabilizers

Stabilizers in PVC are often metal-based compounds such as lead, calcium-zinc, or organotin stabilizers. They function by neutralizing hydrochloric acid (HCl), which can be released during PVC processing due to the breakdown of the polymer chains at high temperatures. By scavenging these HCl molecules, stabilizers prevent the autocatalytic degradation of PVC, which would otherwise lead to discoloration and loss of mechanical properties.

UV absorbers, such as benzotriazoles, and light stabilizers, like hindered amine light stabilizers (HALS), protect PVC from degradation caused by exposure to sunlight. These additives absorb harmful UV radiation and dissipate it as heat, preventing the breakdown of polymer chains that leads to discoloration, brittleness, and loss of mechanical properties.

4.3 Impact Modifiers and Antioxidants

Impact modifiers are often elastomers like acrylics, MBS (methyl methacrylate-butadiene-styrene), or CPE (chlorinated polyethylene). These additives absorb and dissipate the energy from impacts, preventing the propagation of cracks. They do this by creating a more ductile phase within the PVC matrix, which can deform under stress rather than shatter.

The inclusion of impact modifiers is crucial in products like automotive components, building materials (such as window profiles and siding), and bottles, where resistance to impact is essential, especially in cold climates where materials tend to become more brittle.

Antioxidants, such as phenolic compounds, are added to PVC to prevent oxidation during processing and throughout the product’s life. Oxidation can occur due to exposure to oxygen and high temperatures, leading to discoloration and embrittlement of the material. Antioxidants neutralize free radicals formed during oxidation, thus protecting the integrity of the polymer.

Antioxidants are especially important in applications where PVC is exposed to high temperatures or where long-term stability is required, such as in electrical cables, automotive interiors, and construction materials.

4.4 Lubricants

Lubricants used in PVC processing can be internal (affecting the polymer chain interaction) or external (affecting the interaction between PVC and processing equipment). Internal lubricants, such as stearic acid, reduce friction between polymer chains, improving melt flow and processability. External lubricants, like paraffin wax, reduce the friction between the PVC and the machinery, preventing sticking and ensuring a smooth surface finish.

4.5 Fillers

Common fillers include calcium carbonate, talc, and silica. These are added to PVC to improve specific properties, such as stiffness, and to reduce overall material costs. Fillers can enhance rigidity, increase the modulus of elasticity, and improve dimensional stability. Some fillers also provide benefits like improved heat resistance or reduced shrinkage.

While fillers are economical and can improve certain mechanical properties, excessive use can lead to a decrease in impact resistance and flexibility. Therefore, the type and amount of filler must be carefully selected based on the intended application.

4.6 Pigments and Colorants

Pigments are solid particles dispersed throughout the PVC matrix to provide color. Titanium dioxide (TiO₂) is the most common white pigment used for its brightness and UV resistance. Organic and inorganic pigments are used for other colors, depending on the desired hue and resistance to light and chemicals.

4.7 Flame Retardants

Although PVC is inherently flame-retardant due to its chlorine content, additional flame retardants such as antimony trioxide, aluminum hydroxide, or brominated compounds can be added to enhance its fire resistance. These additives work by promoting char formation, releasing water, or forming a protective layer on the surface, which inhibits the spread of flames.

Flame-retardant additives are crucial in applications where fire safety is paramount, such as in building materials, electrical insulation, and transportation interiors.

4.8 Processing Aids

Processing aids, such as acrylic copolymers, improve the flow and melt behavior of PVC during processing. They increase the fusion of PVC particles, resulting in a more homogeneous melt. This improves the quality of the final product by reducing the occurrence of defects like fish eyes, enhancing surface finish, and increasing the strength of the welded joints.

5. What’s the Application of PVC and UPVC?

Polyvinyl Chloride (PVC) and Unplasticized Polyvinyl Chloride (UPVC) are both derivatives of the same base polymer, but they are tailored to meet different functional needs through variations in their composition.

5.1 Applications of PVC

PVC’s flexibility and ease of processing make it a popular choice in a wide range of applications:

1. Electrical Insulation: PVC is widely used in the electrical industry for insulating cables and wires. Its ability to remain flexible, even at lower temperatures, makes it suitable for a variety of electrical applications.

In addition to its flexibility, PVC is valued in the electrical industry for its excellent insulating properties, providing reliable protection against electrical shock and short circuits. PVC insulation also resists moisture, chemicals, and abrasion, which helps to extend the lifespan of electrical cables and wires. Its flame-retardant nature adds an extra layer of safety, making it a preferred material in both residential and industrial settings.

2. Medical Devices: Due to its flexibility, clarity, and biocompatibility, flexible PVC is commonly used in medical tubing, blood bags, and other medical devices. Its adaptability allows it to be formed into complex shapes, making it ideal for intricate medical applications.

3. Packaging: PVC’s versatility extends to packaging materials, particularly in the food and pharmaceutical industries, where it is used to make blister packs, shrink wraps, and cling films. The material’s clarity and ability to seal tightly make it a reliable option for preserving the integrity of products.

4. Flooring and Wall Coverings: The flexibility and durability of PVC make it suitable for flooring and wall coverings, especially in commercial settings where high foot traffic demands a resilient material. Vinyl flooring, which is made from PVC, is widely appreciated for its ease of maintenance, moisture resistance, and wide range of aesthetic options.

5. Consumer Goods: PVC’s malleability allows it to be molded into a variety of shapes, making it a common material in everyday consumer products such as hoses, inflatable structures, and even toys.

5.2 Applications of UPVC

UPVC, with its superior rigidity and environmental resistance, is preferred in applications where structural integrity and long-term performance are paramount:

1. Building and Construction: UPVC is extensively used in the construction industry, particularly for window frames, doors, and conservatories. The material’s high resistance to weathering, coupled with its insulating properties, makes it an ideal choice for energy-efficient buildings. UPVC windows and doors provide excellent thermal insulation, reducing energy consumption for heating and cooling. Additionally, UPVC does not corrode, which makes it a superior alternative to metal for plumbing and drainage systems, where long-term exposure to moisture and chemicals is a concern.

2. Piping Systems: UPVC is the material of choice for plumbing and sewage pipes due to its high chemical resistance and ability to withstand the pressure of flowing water. Unlike metal pipes, UPVC pipes do not rust or scale, ensuring a longer lifespan and reduced maintenance costs. Its resistance to UV radiation also makes it suitable for outdoor piping that is exposed to sunlight.

3. Cladding and Roofing: UPVC’s durability and low maintenance requirements make it suitable for cladding and roofing applications. It is often used in facades, soffits, and fascia boards, providing a weatherproof barrier that protects the underlying structures from the elements.

4. Electrical Conduits: Due to its non-conductive nature and resistance to chemicals, UPVC is used in electrical conduit systems to protect wiring and cables from damage.PVC-U electrical conduit is often favored as a photovoltaic solar conduit due to its superior UV resistance, which is attributed to the absence of plasticizers.

This makes it more durable and reliable for protecting wiring and cables in solar installations, ensuring long-lasting performance in outdoor environments where exposure to sunlight is a critical factor. In contrast, PVC-P, with plasticizers, may not offer the same level of UV resistance, making PVC-U a preferred choice for solar projects.

5. Industrial Applications: In industrial settings, UPVC is used for applications requiring a material that can withstand harsh chemicals and high temperatures, such as in chemical processing plants, where the material’s resistance to corrosion and fire is critical.

6. What’s the Difference Between PVC-P Conduit and UPVC Conduit?

PVC-P (Plasticized Polyvinyl Chloride) conduit and UPVC (Unplasticized Polyvinyl Chloride) conduit are both widely used in electrical systems for protecting wiring and cables. While they share the same basic polymer, their different formulations give them distinct properties that make them suitable for different applications.

| PVC-P Electrical Conduit vs. PVC-U Electrical Conduits | ||

|---|---|---|

| Property | PVC-P Conduit | PVC-U Conduit |

| 灵活性 | Highly flexible due to the presence of plasticizers | Rigid, with no added plasticizers |

| Durability | Lower long-term durability; can become brittle over time due to plasticizer migration | High durability; retains properties over time |

| UV Resistance | Moderate; can degrade over time when exposed to sunlight | High; excellent resistance to UV radiation |

| Chemical Resistance | Moderate; some plasticizers may react with chemicals | High; resistant to most chemicals and corrosive environments |

| Fire Resistance | Good, but may emit more smoke and toxic gases when burned | Excellent; self-extinguishing and emits less smoke |

| Impact Resistance | Lower impact resistance due to softer material | High impact resistance, suitable for harsh environments |

| Ease of Installation | Easier to install in tight spaces due to flexibility | More challenging to install in complex configurations due to rigidity |

| Installation Cost | Lower | Higher |

| Long-Term Maintenance | May require more frequent maintenance due to potential brittleness | Low maintenance; highly durable |

| Typical Applications | Indoor wiring, temporary installations, complex routing | Outdoor and underground wiring, industrial environments |

6.1 Material Composition and Impact on Properties

The primary difference between PVC-P and UPVC electrical conduit lies in the presence or absence of plasticizers.

PVC-P is created by adding plasticizers to the base PVC resin. These additives soften the material, making it flexible and easier to work with during installation. However, the inclusion of plasticizers can also affect the material’s long-term stability.

The flexibility of PVC-P makes it ideal for environments where the conduit needs to bend or adapt to complex routes. However, plasticizers can migrate over time, leading to a gradual loss of flexibility and an increased risk of brittleness. This can affect the longevity of the installation, especially in environments with high temperatures or exposure to chemicals.

UPVC is PVC in its rigid, unplasticized form. Without plasticizers, UPVC retains its inherent stiffness, making it a durable and long-lasting material.

The rigidity of UPVC provides excellent structural integrity, making it suitable for environments where the conduit needs to withstand physical impacts or harsh conditions. Its stable composition ensures that UPVC maintains its properties over time, even in challenging environments, making it a reliable choice for long-term installations.

6.2 UV Resistance

While PVC-P conduits can be used outdoors, their UV resistance is lower compared to UPVC. Prolonged exposure to sunlight can accelerate the degradation of plasticizers, leading to embrittlement and potential failure over time. For this reason, PVC-P Conduit is generally recommended for indoor use or for temporary outdoor installations where the conduit will not be exposed to direct sunlight for extended periods.

UPVC conduit offers superior UV resistance, making it an excellent choice for outdoor installations. It can withstand prolonged exposure to sunlight without significant degradation, ensuring long-term performance in outdoor environments.

6.3 Chemical Resistance

The presence of plasticizers can make PVC-P conduit more susceptible to chemical attack, particularly from solvents, oils, and certain types of acids. This limits its use in environments where exposure to harsh chemicals is expected. However, for general-purpose indoor applications, PVC-P’s chemical resistance is usually sufficient.

The chemical resistance of UPVC conduit is significantly higher, making it suitable for industrial environments where exposure to chemicals, such as acids, alkalis, and corrosive agents, is common. Its resistance to chemical attack ensures that the conduit will not degrade or fail when exposed to these substances, providing reliable protection for electrical wiring.

6.4 Flexural Strength

The flexibility of PVC-P conduit makes it ideal for use in applications where the conduit needs to be routed through tight spaces, around corners, or in environments where the conduit might need to move or flex after installation. This makes it particularly suitable for indoor electrical systems in residential and commercial buildings, where ease of installation and adaptability are important.

The rigidity of UPVC conduit makes it less adaptable to tight spaces but provides superior mechanical strength. This makes UPVC conduit the preferred choice for environments where the conduit needs to withstand external pressures, such as underground installations, or where it needs to provide long-term structural support, such as in industrial settings.

6.5 Impact Resistance

While PVC-P conduit is flexible, its impact resistance is generally lower than that of UPVC conduit. This means that PVC-P conduits are more likely to be damaged by physical impacts, particularly in environments where heavy machinery or frequent movement of materials is common.

The rigidity of UPVC conduit gives it high impact resistance, making it suitable for environments where the conduit is at risk of being struck or crushed. This property is particularly important in industrial or underground applications, where the conduit needs to protect electrical wiring from external forces.

6.6 Cost Consideration

When comparing the cost of PVC-P and uPVC conduits, it is important to consider both the initial expenses and the long-term value.

PVC-P conduits generally have a lower initial cost, making them an appealing choice for projects with tight budgets or temporary installations. Their flexibility simplifies the installation process, potentially reducing labor costs, especially in complex or retrofit projects.

However, PVC-P conduits may have a shorter lifespan due to the potential for plasticizer migration, leading to embrittlement. In environments exposed to heat, UV radiation, or chemicals, this can result in higher maintenance and replacement costs over time, diminishing their long-term value.

UPVC conduits, on the other hand, come with a higher upfront cost, both in material and installation, due to their rigidity and the more complex planning required for installation.

Despite this, UPVC conduits often offer superior long-term value. Their durability, chemical resistance, and stability reduce the likelihood of maintenance or replacement, making them a more cost-effective option in the long run, particularly in environments where long-term reliability is essential.

7. Conclusion

Selecting the right conduit for an electrical system requires careful consideration of the specific needs and environmental conditions of the project. PVC-P conduits, with their flexibility and ease of installation, are well-suited for indoor and temporary installations where adaptability and cost are key concerns. On the other hand, UPVC conduits, with their superior durability, chemical resistance, and UV stability, are the better choice for outdoor, industrial, and long-term applications where reliability and long-term value are critical.

By understanding the differences between PVC-P and UPVC conduits, you can make informed decisions that ensure the safety, durability, and cost-effectiveness of their electrical installations. Whether the priority is flexibility, environmental resistance, or long-term performance, the right choice of conduit can significantly impact the success and longevity of the project.

Ctube is a manufacturer and supplier of PVC conduit and fittings based in China. Ctube specializes in producing a wide range of PVC conduits and fittings products that cater to electrical installation. Ctube is committed to delivering high-quality products that comply with relevant testing and certification standards, such UL listed, CSA certified, AS/NZS 2053 standards.

In addition to these standard products, Ctube also provides specialized conduit series to address specific industry demands. Photovoltaic and Solar Series are tailored solutions for solar energy applications, ensuring durability and performance in outdoor environments. Low-Smoke Halogen-Free Series Conduits are designed for safety to reduce smoke and toxic emissions.

Ctube’s dedication to customer satisfaction is evident in their ability to provide tailored solutions. If you have projects requirement, please contact us.

FAQs

1. What’s the different between PVC and CPVC Electrical conduit?

PVC is generally preferred for most standard electrical conduit applications due to its lower cost and sufficient performance in typical conditions. CPVC is the better choice for environments with higher temperatures or aggressive chemicals, where its enhanced properties can provide added reliability and longevity. For projects that involve chemicals that could potentially react to chlorine, standard PVC is the preferred option.

2. What’s the different between UPVC and CPVC Electrical conduit?

The fundamental difference between UPVC and CPVC is that the former is produced without the use of plasticizers, whereas the latter is produced with the use of plasticizers and is also chlorinated. They both can used in electrical conduit, CPVC has a higher melting point than UPVC.

3. How do temperature changes affect PVC conduits?

PVC conduits have a good tolerance for temperature variations, but they can become brittle in extremely cold conditions or soften in high heat. It’s essential to consider the climate of the installation area and choose the appropriate type of PVC conduits accordingly.