目录

切换1. Brief Introduction and Overview of Plumbing PVC and Electrical Conduit PVC

Polyvinyl Chloride (PVC) is a synthetic plastic polymer that has become indispensable in modern construction and manufacturing. Its unique combination of properties—strength, lightweight, chemical and moisture resistance—makes it suitable for a broad range of applications. In the realm of building and infrastructure, two primary types of PVC stand out: plumbing PVC and electrical conduit PVC.

Plumbing PVC and electrical conduit PVC may seem similar, but they serve distinct purposes. Plumbing PVC is designed to handle water pressures and temperatures, enhanced with additives for flexibility and chemical resistance. In contrast, electrical conduit PVC prioritizes flame resistance and UV stability for protecting wiring.Electrical conduit PVC meets stringent fire safety standards, unlike plumbing PVC, which focuses on chemical and moisture resistance. Plumbing PVC is rated for water pressure, while electrical conduit PVC withstands environmental and mechanical stresses. Plumbing PVC is generally more accessible and cost-effective, whereas electrical conduit PVC, due to its specialized properties, may cost more and is commonly sourced through electrical suppliers.

Understanding the differences between these two types is crucial for ensuring the safety, efficiency, and longevity of various installations. This article aims to elucidate these differences, providing a comprehensive guide to help you choose the correct type of PVC for your specific applications.

2. Plumbing PVC: A Comprehensive Exploration

Plumbing PVC, or Polyvinyl Chloride, represents a cornerstone in modern plumbing infrastructure, valued for its durability, versatility, and reliability in conveying water, wastewater, and various fluids across residential, commercial, and industrial applications. This synthetic polymer has revolutionized the plumbing industry, offering robust solutions that ensure efficient water management and system integrity.

2.1 Definition and Primary Uses of Plumbing PVC

Plumbing PVC is a thermoplastic polymer renowned for its resilience, chemical inertness, and ease of installation. It is specifically engineered to meet stringent regulatory standards for water quality and safety, making it a preferred choice in plumbing installations worldwide. From simple household plumbing to complex industrial applications, Plumbing PVC serves a critical role in maintaining reliable water supply and sanitation networks.

2.2 Common Applications in Residential, Commercial, and Industrial Plumbing

The versatility of Plumbing PVC is evident across a broad spectrum of applications

Residential Use: In homes, Plumbing PVC pipes are integral to water supply lines, drainpipes, sewage systems, and household irrigation. Their ease of installation and resistance to corrosion ensure dependable performance and longevity, contributing to sustainable water management practices within residential communities.

Commercial Use: In commercial settings, such as office buildings, hotels, hospitals, and retail establishments, Plumbing PVC facilitates efficient plumbing solutions. It is utilized in restroom facilities, kitchen installations, and general plumbing infrastructure to ensure uninterrupted water flow and sanitation compliance.

Industrial Use: Across industries, from manufacturing plants to chemical processing facilities, Plumbing PVC plays a crucial role in handling aggressive chemicals, process fluids, and industrial wastewater. Its chemical resistance and robust construction make it indispensable for maintaining operational efficiency and environmental safety.

2.3 Key Characteristics of Plumbing PVC Pipes

Plumbing PVC pipes possess several key attributes that contribute to their widespread adoption and usage:

Durability: PVC pipes are renowned for their durability and resistance to physical damage, including impact and abrasion. This inherent strength ensures long-term performance and reliability, reducing maintenance costs and enhancing system longevity.

Flexibility: Despite their robustness, Plumbing PVC pipes remain flexible during installation, allowing for easy handling and adaptation to various plumbing configurations. This flexibility minimizes installation time and labor costs, making it a preferred choice for both professional installers and DIY enthusiasts.

Chemical Resistance: One of the hallmark characteristics of Plumbing PVC is its exceptional resistance to corrosion from acids, alkalis, and salts commonly found in water and wastewater systems. This chemical inertness ensures that PVC pipes maintain water quality, prevent contamination, and comply with stringent health and safety regulations.

Pressure Capacity: Plumbing PVC pipes are available in different pressure ratings to accommodate a wide range of plumbing requirements. From low-pressure applications in residential settings to high-pressure industrial environments, PVC pipes offer consistent performance and structural integrity under varying operational conditions.

2.4 Certifications for Plumbing PVC

2.4.1 NSF/ANSI Standard 61

NSF/ANSI 61: This certification ensures that plumbing PVC pipes and fittings do not leach harmful contaminants into drinking water. Products with this certification are deemed safe for use in potable water systems, which is crucial for public health.

2.4.2 ASTM Standards

ASTM D1785: This standard specifies the requirements for PVC plastic pipes in Schedules 40, 80, and 120, used in pressure applications such as water supply systems. It includes criteria for dimensions, pressure ratings, and material properties.

ASTM D2241: This standard covers PVC pressure-rated pipes (SDR Series) designed for higher-pressure applications. It provides guidelines for wall thickness and diameter ratios to ensure the pipes can handle the specified pressure.

ASTM F441: Specifies requirements for chlorinated polyvinyl chloride (CPVC) pipes. CPVC pipes are often used for hot and cold water distribution due to their superior temperature resistance compared to standard PVC.

ASTM D2665: This standard covers PVC drain, waste, and vent (DWV) pipes and fittings. It includes specifications for dimensions and performance requirements to ensure the system effectively removes waste and vents gases.

ASTM D2846: Covers CPVC hot and cold water distribution systems, specifying requirements for dimensions, pressure ratings, and performance criteria to ensure reliable water delivery.

2.4.3 UPC (Uniform Plumbing Code) Certification

UPC Certification: Provided by the International Association of Plumbing and Mechanical Officials (IAPMO), this certification ensures that plumbing PVC products meet the safety and performance standards outlined in the Uniform Plumbing Code. It includes testing for durability, pressure resistance, and overall product safety.

2.4.4 CSA (Canadian Standards Association)

CSA B137.3: This standard specifies requirements for rigid PVC pipe used in pressure applications, including dimensions, pressure ratings, and performance criteria.

CSA B181.2: Covers PVC drain, waste, and vent (DWV) systems, providing guidelines for dimensions, material properties, and performance to ensure effective waste removal and venting.

2.4.5 IAPMO R&T

IAPMO Research and Testing (R&T): Certifies products to ensure they meet applicable standards for performance and safety, verifying that the products perform as expected under specified conditions.

2.5 Common Types: Schedule 40 and Schedule 80

Plumbing PVC is categorized into distinct schedules, each tailored to specific operational demands:

Schedule 40 PVC: This type of PVC is characterized by its versatility and cost-effectiveness. It features a thinner wall compared to Schedule 80, making it lightweight and easy to handle during installation. Schedule 40 PVC is suitable for low to moderate pressure applications, including residential plumbing, irrigation systems, and pool installations. Its affordability and ease of use make it a popular choice for both professional contractors and homeowners embarking on plumbing projects.

Schedule 80 PVC: Designed for applications requiring higher strength and durability, Schedule 80 PVC boasts a thicker wall and higher pressure rating. It is commonly used in industrial plumbing, underground utilities, and environments where pipes are exposed to greater mechanical stresses or pressure fluctuations. Schedule 80 PVC ensures reliable performance and longevity in demanding conditions, safeguarding critical plumbing systems against operational disruptions and ensuring regulatory compliance.

2.6 Advantages of Plumbing PVC

Beyond its key characteristics and types, Plumbing PVC offers several distinct advantages:

Cost-Effectiveness: PVC pipes are economical to manufacture and install, contributing to lower overall project costs without compromising on quality or performance.

Environmental Sustainability: PVC is recyclable and contributes to sustainable building practices by conserving natural resources and reducing carbon footprint during production and disposal.

Ease of Maintenance: PVC pipes require minimal maintenance due to their resistance to corrosion and chemical degradation, resulting in fewer disruptions and lower lifecycle costs for plumbing systems.

Versatility in Design: PVC pipes can be easily customized to meet specific project requirements, including varying diameters, lengths, and fittings, ensuring seamless integration into existing infrastructure or new construction projects.

2.7 Challenges and Considerations

While Plumbing PVC offers numerous benefits, it is essential to consider potential challenges:

Temperature Sensitivity: PVC pipes can become brittle at very low temperatures, impacting their performance in cold climates or outdoor applications.

UV Resistance: Standard PVC may degrade when exposed to prolonged sunlight, necessitating UV-stabilized formulations for outdoor installations.

Material Compatibility: Certain chemicals and solvents may affect PVC’s integrity over time, requiring careful consideration of application-specific requirements and material compatibility tests.

3. Electrical Conduit PVC: A Comprehensive Exploration

Electrical conduit PVC (Polyvinyl Chloride) is a versatile and essential component in modern electrical installations, designed to protect and route electrical wiring safely and efficiently. This robust material is engineered to meet stringent safety standards while offering flexibility, durability, and resistance to environmental factors, making it indispensable in residential, commercial, and industrial applications.

3.1 Definition and Primary Uses of Electrical Conduit PVC

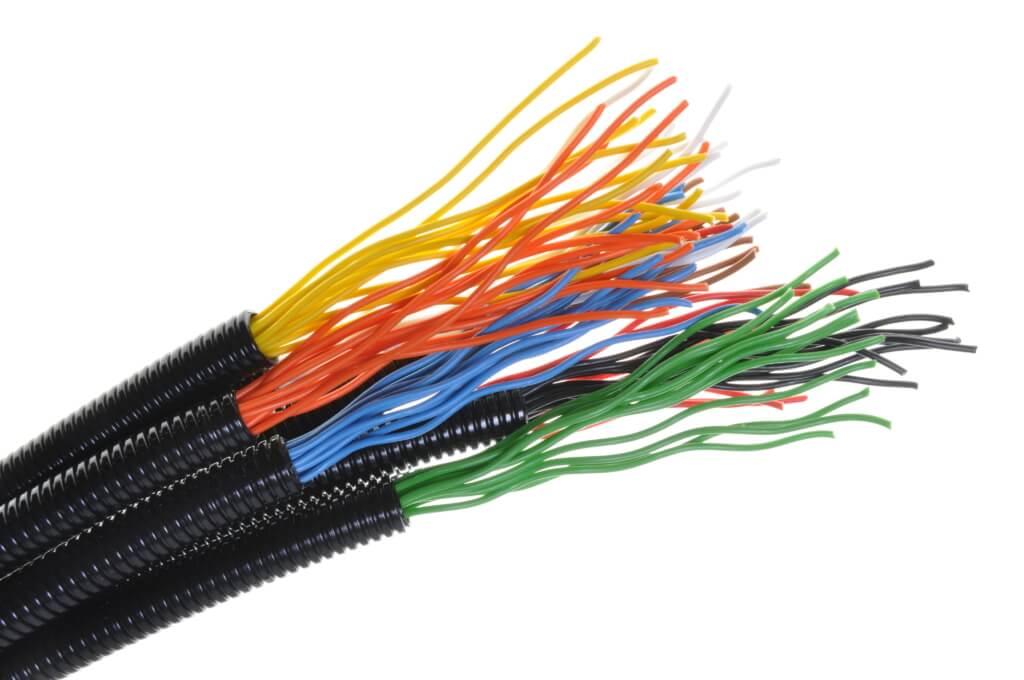

Electrical conduit PVC serves as a protective channel for electrical wires, cables, and conductors, shielding them from physical damage, moisture, and environmental elements. It ensures compliance with electrical codes and safety regulations by securely housing electrical components and preventing hazards such as short circuits and electrical fires. The primary function of PVC conduit is to provide a reliable pathway for electrical wiring, enhancing system integrity and operational safety.

3.2 Common Applications in Electrical Wiring Protection

The versatility of Electrical Conduit PVC is evident in a wide range of applications

Residential Use: In homes, PVC conduit is utilized for routing electrical wiring through walls, ceilings, and underground installations. It protects wiring from mechanical damage, enhances electrical safety, and facilitates organized wiring layouts, contributing to the efficiency and reliability of residential electrical systems.

Commercial Use: Across commercial buildings, including offices, retail spaces, and healthcare facilities, PVC conduit supports comprehensive electrical infrastructure. It accommodates overhead and underground wiring configurations, safeguards against electromagnetic interference (EMI), and simplifies maintenance and expansion of electrical networks, ensuring uninterrupted power supply and operational continuity.

Industrial Use: In industrial environments such as manufacturing plants, factories, and warehouses, PVC conduit withstands harsh conditions and heavy-duty applications. It defends electrical cables against corrosive substances, extreme temperatures, and mechanical stresses, ensuring resilience and reliability in critical industrial processes and operations.

3.3 Key Characteristics of Electrical Conduit PVC

Electrical conduit PVC exhibits several key characteristics essential for its performance and reliability in electrical installations:

Flame Resistance and Safety Standards: PVC conduit is inherently flame retardant, designed to resist ignition and combustion. It complies with stringent safety standards and building codes, ensuring protection against fire hazards caused by electrical faults or overheating, making it suitable for both residential and commercial applications.

UV Resistance and Suitability for Outdoor Use: PVC conduit is formulated with UV stabilizers to withstand prolonged exposure to sunlight without degradation. This UV resistance ensures long-term durability and performance in outdoor installations, including exposed wiring runs and applications where conduit is exposed to weather elements.

Non-Conductive Properties and Electrical Insulation: As a non-conductive material, PVC conduit effectively insulates electrical wiring from external electrical fields and reduces electromagnetic interference (EMI). It prevents electrical shorts, grounding issues, and ensures the integrity and safety of electrical systems, particularly in environments with sensitive electronic equipment.

3.4 Certifications for Electrical Conduit PVC

3.4.1 UL (Underwriters Laboratories) Certification

UL 651: Covers Schedule 40, 80, Type EB, and A Rigid PVC Conduit and Fittings, ensuring suitability for electrical installations. This includes testing for flame resistance, impact resistance, and other critical performance metrics.

UL 514B: Applies to conduit, tubing, and cable fittings, ensuring they meet performance and safety requirements, including durability and proper fit.

UL 1653: Covers electrical non-metallic tubing (ENT), ensuring it is suitable for use in electrical installations, with testing for flexibility, impact resistance, and flame resistance.

3.4.2 NEC (National Electrical Code) Compliance

NEC Compliance: Ensures that PVC conduit products are safe for electrical wiring applications and meet the necessary safety standards set by the National Fire Protection Association (NFPA). Compliance with the NEC is mandatory for electrical installations in the United States.

3.4.3 NEMA (National Electrical Manufacturers Association) Standards

NEMA TC 2: Covers electrical plastic conduit (EPC-40 and EPC-80), specifying requirements for material properties, dimensions, and performance to ensure consistency and reliability in electrical installations.

NEMA TC 3: Covers PVC fittings for use with rigid PVC conduit and tubing, ensuring that fittings meet the same high standards for performance and safety.

3.4.4 IEC (International Electrotechnical Commission) Standards

IEC 61386: Specifies requirements for conduit systems for electrical installations, including mechanical and electrical properties to ensure safety and performance.

3.4.5 CSA (Canadian Standards Association)

CSA C22.2 No. 211.0: General requirements and test methods for conduit, tubing, and fittings, ensuring they meet performance and safety standards.

CSA C22.2 No. 211.1: Specific requirements for rigid PVC conduit, including material properties, dimensions, and performance criteria to ensure reliable electrical installations.

3.4.6 ASTM Standards for PVC Electrical Conduit

ASTM D1784: Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds – This standard specifies the properties and requirements of rigid PVC compounds used for manufacturing PVC conduit.

ASTM D2564: Standard Specification for Solvent Cements for Poly(Vinyl Chloride) (PVC) Plastic Piping Systems – Specifies the requirements for solvent cements used for joining PVC pipes and conduits.

ASTM F512: Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and Fittings for Underground Installation – Covers requirements for smooth-wall PVC conduits and fittings intended for underground installation.

ASTM F1488: Standard Specification for Coextruded Composite Pipe – This standard covers coextruded composite pipe composed of a PVC electrical conduit with an integral rigid PVC, and covers requirements for smooth-wall and corrugated-wall coextruded conduit.

3.5 Common Types: Rigid PVC and Electrical Non-metallic Tubing (ENT)

Electrical conduit PVC is available in distinct types tailored to specific installation requirements and environmental conditions:

Rigid PVC Conduit (Schedule 40 and Schedule 80): Rigid PVC conduit is characterized by its robust construction and mechanical strength, available in different wall thicknesses designated as Schedule 40 (standard duty) and Schedule 80 (heavy duty). Schedule 40 PVC conduit is flexible yet sturdy, suitable for general-purpose applications such as residential wiring and light commercial installations. Schedule 80 PVC conduit offers enhanced durability and pressure resistance, making it ideal for industrial settings, underground utilities, and applications requiring greater structural integrity.

Electrical Non-metallic Tubing (ENT): ENT, often referred to as “smurf tube” due to its distinctive blue color, is a flexible PVC conduit designed for lightweight applications. It offers ease of installation in confined spaces, bends easily without kinking, and is commonly used in residential and light commercial wiring projects where flexibility, cost-effectiveness, and ease of handling are priorities.

3.6 Advantages of Electrical Conduit PVC

Beyond its key characteristics and types, Electrical Conduit PVC offers several advantages:

Durability and Longevity: PVC conduit is resistant to corrosion, abrasion, and chemical degradation, ensuring prolonged service life and minimal maintenance requirements. It withstands environmental stresses and mechanical impacts, providing reliable performance in diverse operating conditions.

Cost-Effectiveness: PVC conduit is cost-effective to manufacture, install, and maintain compared to traditional metallic conduits. It reduces overall project costs while delivering superior electrical protection and safety benefits, making it a preferred choice for budget-conscious projects.

Environmental Sustainability: PVC conduit contributes to sustainable building practices through its recyclability and energy-efficient manufacturing processes. It promotes resource conservation, reduces carbon footprint, and supports green building initiatives aimed at minimizing environmental impact.

Versatility and Adaptability: PVC conduit can be easily customized to accommodate specific project requirements, including varying diameters, lengths, and fittings. It facilitates seamless integration into existing infrastructure or new construction projects, providing flexibility and adaptability in electrical system design.

3.7 Challenges and Considerations

While Electrical Conduit PVC offers numerous benefits, it is essential to consider potential challenges:

Temperature Sensitivity: PVC conduit can become brittle at very low temperatures, affecting its flexibility and impact resistance in cold climates or outdoor applications.

UV Exposure: Standard PVC may degrade when exposed to prolonged sunlight, necessitating UV-stabilized formulations for outdoor installations to maintain long-term performance and durability.

Material Compatibility: PVC’s compatibility with certain chemicals and solvents may vary, requiring assessment of application-specific requirements and compatibility testing to ensure optimal performance and longevity.

4. Key Differences Between Plumbing PVC and Electrical Conduit PVC

Plumbing PVC (Polyvinyl Chloride) and Electrical Conduit PVC are essential materials in construction and infrastructure projects, each tailored to specific functional requirements in plumbing and electrical installations, respectively. Despite some visual similarities, these materials differ significantly in their composition, properties, applications, and regulatory standards.

4.1 Material Composition and Additives

The composition of Plumbing PVC and Electrical Conduit PVC is customized with distinct additives to meet the performance demands of their intended applications:

Plumbing PVC: Engineered to withstand the pressures and temperatures associated with water conveyance, Plumbing PVC incorporates additives such as plasticizers, stabilizers, and impact modifiers. These additives enhance the material’s flexibility, chemical resistance, and durability against corrosion caused by exposure to water, sewage, and other fluids commonly found in plumbing systems.

Electrical Conduit PVC: Designed primarily for protecting electrical wiring and cables, Electrical Conduit PVC includes additives that enhance flame resistance and UV stability. These additives ensure the conduit’s ability to withstand exposure to electrical currents, protect against fire hazards, and maintain structural integrity in various environmental conditions, including sunlight exposure.

4.2 Size, Color Coding, and Markings

To prevent misapplication and facilitate easy identification, Plumbing PVC and Electrical Conduit PVC are typically manufactured in distinct colors with specific markings and size ranges

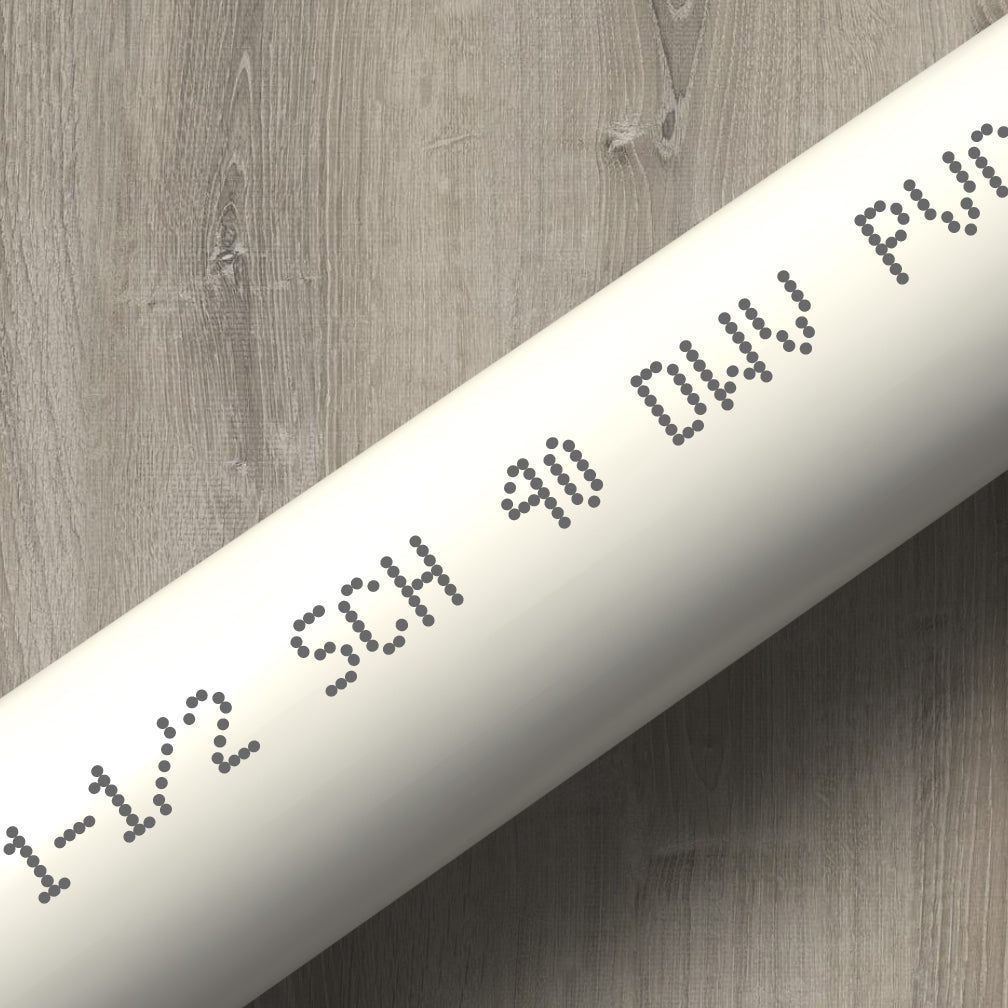

Plumbing PVC:

– Color: Commonly produced in white or off-white colors, adhering to standardized color codes that vary by region.

– Size: Available in a wide range of sizes, typically from 1/8″ to 24″ and larger, to meet various plumbing needs from small household pipes to large industrial systems.

– Markings:

– Manufacturer details

– Product specifications

– Compliance with relevant plumbing standards

Electrical Conduit PVC:

– Color: Typically manufactured in gray or dark gray colors, making it easily recognizable on construction sites and within electrical installations.

– Size: Generally available in sizes ranging from 1/2″ to 8″ in diameter, ensuring compatibility with electrical fittings and providing sufficient space for pulling wires through bends and curves.

– Markings:

– Embossed markings or printed labels

– Indications of compliance with industry standards such as UL, CSA

– Certification of suitability for electrical wiring protection and adherence to safety regulations

4.3 Fire Resistance and Safety Standards

Fire resistance properties and compliance with safety standards are critical aspects distinguishing Plumbing PVC from Electrical Conduit PVC:

Plumbing PVC: While designed to withstand exposure to water and chemicals, Plumbing PVC typically has lower fire resistance compared to Electrical Conduit PVC. It meets safety standards related to water purity, structural integrity under pressure, and resistance to environmental factors such as sunlight and heat. However, it does not require the same level of fire resistance as Electrical Conduit PVC, as fire hazards are less of a concern in plumbing applications.

Electrical Conduit PVC: Engineered with stringent fire resistance properties, Electrical Conduit PVC complies with standards set by ASTM and NEC for containing electrical fires and preventing the spread of flames. These standards ensure the conduit can safely encase electrical wiring and withstand high temperatures generated during electrical fault conditions. Electrical Conduit PVC’s fire-resistant additives and construction make it essential for protecting wiring systems in residential, commercial, and industrial settings.

4.4 Pressure Ratings and Durability

The ability to withstand mechanical stress, pressure variations, and environmental conditions varies between Plumbing PVC and Electrical Conduit PVC:

Plumbing PVC: Rated for specific pressure levels required in plumbing applications, Plumbing PVC pipes and fittings are rigorously tested to endure varying water pressures and temperature fluctuations. Its flexibility, chemical resistance, and structural integrity contribute to long-term durability and minimal maintenance in plumbing systems.

Electrical Conduit PVC: Designed to withstand mechanical impacts, environmental stresses, and high-pressure conditions, Electrical Conduit PVC features robust construction and higher pressure ratings compared to Plumbing PVC. Variants such as Schedule 40 and Schedule 80 Electrical Conduit PVC offer different wall thicknesses and pressure resistance levels, making them suitable for both indoor and outdoor electrical installations where durability is paramount.

4.5 Cost and Market Availability

Cost-effectiveness and market availability are influenced by demand, production volumes, and distribution channels for each type of PVC.

Plumbing PVC: Due to its widespread use in residential, commercial, and industrial plumbing applications, Plumbing PVC is readily available through plumbing supply outlets, hardware stores, and construction material suppliers. Its affordability and accessibility cater to a broad customer base seeking reliable piping solutions for water and sewage systems.

Electrical Conduit PVC: While generally priced higher than Plumbing PVC due to its specialized properties and adherence to stringent safety standards, Electrical Conduit PVC is widely available through electrical supply channels and distributors. The market for Electrical Conduit PVC reflects its critical role in new construction projects, infrastructure developments, and renovations requiring reliable electrical wiring protection.

4.6 Sustainability Aspects

Energy Efficiency: Both Plumbing PVC and Electrical Conduit PVC are energy-efficient throughout their lifecycle. Their lightweight nature facilitates easier and more energy-efficient transportation and installation, leading to overall energy savings and reduced environmental impact.

Environmental Impact: Advancements in PVC manufacturing have significantly reduced environmental impact. Modern processes focus on reducing emissions and optimizing resource use, which leads to less waste and promotes sustainable development. These improvements support eco-friendly building practices and contribute to a smaller ecological footprint.

Recycling Initiatives: PVC recycling programs emphasize closed-loop recycling, where post-consumer PVC waste is repurposed into new products. This practice reduces landfill waste, conserves natural resources, and minimizes the need for new raw materials, enhancing the overall sustainability of PVC products.

5. Conclusion

In conclusion, the choice between plumbing PVC and electrical conduit PVC hinges on their distinct properties and intended applications. Plumbing PVC, renowned for its robustness and chemical resistance, is primarily used in water distribution systems. Its smooth interior ensures efficient fluid flow while its resistance to corrosion and chemicals prolongs service life in aggressive environments. In contrast, electrical conduit PVC serves as a protective housing for electrical wiring, safeguarding against physical damage, moisture ingress, and fire hazards. Its non-conductive nature prevents electrical shorts, making it indispensable in residential, commercial, and industrial settings.

As the leading and professional PVC conduit and fittings manufacturer in China, Ctube specializes in developing and producing innovative solutions for cable management and protection. Our extensive product range includes UL listed PVC conduit pipes, solar conduit and fittings, halogen-free conduit and fittings, as well as AS/NZS 2053 and British standard PVC conduit and fittings. Backed by certifications such as UL, AS/NZS 2053, CSA, CE, ROHS, IEC, and more, we ensure our products meet global standards of quality and safety.

At Ctube, we are dedicated to delivering superior products and services promptly and efficiently to our customers worldwide. Whether you’re seeking robust solutions for residential, commercial, or industrial applications, Ctube offers tailored PVC conduit and fittings designed to meet your specific needs.

常问问题

1. Can I use PVC pipe instead of conduit?

No, PVC pipe is not designed for electrical applications and lacks the necessary properties such as flame retardance and UV resistance, which are critical for electrical safety.

2. What are the key differences between PVC pipe and PVC electrical conduit?

PVC pipe is used for plumbing and drainage, whereas PVC electrical conduit is used to protect electrical wiring. Electrical conduit has specific features like flame retardance and UV protection, which are not present in regular PVC pipes.

3. Is PVC conduit suitable for outdoor applications?

Yes, PVC conduit is suitable for outdoor applications. It is resistant to moisture, chemicals, and UV radiation, making it ideal for protecting electrical wiring in various environmental conditions.

4. What are the advantages of using PVC conduit over metal conduit?

PVC conduit is lightweight, easier to install, non-corrosive, and generally more cost-effective than metal conduit. It also provides good insulation and is resistant to chemicals and moisture.