1. Plastic Conduit Introduction

In the realm of electrical systems, conduit plays a crucial role in protecting and routing wiring. Among the various types of conduit available, plastic conduit stands out due to its versatility, cost-effectiveness, and ease of use.

Plastic conduit is a type of tubing made from durable plastic materials, such as PVC (Polyvinyl Chloride), used to house and protect electrical wires. Unlike metal conduit, plastic conduit is lightweight, corrosion-resistant, and often more flexible, making it a popular choice for a wide range of electrical installations.

Plastic conduits serve a vital function in electrical systems by shielding wires from physical damage, moisture, and chemical exposure, ensuring the safety and longevity of electrical circuits. They are utilized in various environments, from residential homes to industrial complexes, demonstrating their adaptability and importance in modern electrical infrastructure.

In this article, we aim to provide a comprehensive guide to plastic conduit, covering everything you need to know. We will explore the different types of plastic conduit, their key characteristics, and the myriad applications in which they excel. Additionally, we will delve into the installation and maintenance processes, compare plastic conduit with other types, and discuss the relevant regulatory standards.

2. What are plastics, and what are the common types of plastics?

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient.

One important classification of plastics is the degree to which the chemical processes used to make them are reversible or not.

Thermoplastics do not undergo chemical change in their composition when heated and thus can be molded repeatedly. Examples include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC).

2.1 Polypropylene (PP)

Polypropylene, commonly referred to as PP, is a highly versatile thermoplastic material known for its excellent chemical resistance and mechanical properties. First synthesized in 1951 by scientists Paul Hogan and Robert Banks at Phillips Petroleum, PP has quickly become a preferred material in various industries due to its elasticity, toughness, and lightweight nature.

Its fatigue resistance makes it an ideal substitute for some metal components. Notably, PP is used extensively in the packaging industry, as well as in the manufacture of plastic parts for electrical devices, machinery, automobiles, and consumer products. Additionally, PP’s excellent electrical insulation characteristics make it suitable for capacitors and wire insulation. PP is also environmentally friendly, being 100% recyclable, making it a sustainable choice for many applications.

2.2 Polyvinyl Chloride (PVC)

Polyvinyl chloride, commonly known as PVC, is a versatile thermoplastic material available in rigid and flexible forms. First synthesized in 1872 and commercially produced in the 1920s by the B.F. Goodrich Company, PVC has become a staple in various industries.

Rigid PVC is used for high-strength pipes in plumbing and agriculture, while flexible PVC is used for insulation on electrical wires and exterior walls in the form of vinyl siding. Notable characteristics of PVC include its high density, hardness, durability, outstanding tensile strength, and resistance to environmental and chemical degradation.

2.3 Polyethylene (PE)

Polyethylene, commonly referred to as PE, is one of the most widely used thermoplastic materials in the world, known for its versatility and ease of processing. First synthesized by accident in 1933 by Eric Fawcett and Reginald Gibson at the Imperial Chemical Industries,

PE has since become indispensable in various industries. PE is available in several grades, including low-density (LDPE), high-density (HDPE), and linear low-density (LLDPE), each with distinct properties. Notable characteristics of PE include its excellent chemical resistance, flexibility, and toughness.

It is extensively used in the production of plastic films, containers, pipes, and household goods. PE’s lightweight nature and durability make it ideal for packaging applications, while its excellent insulation properties are valuable in the electrical and telecommunications industries. Moreover, PE is recyclable, contributing to its status as a sustainable material choice for a wide range of applications.

2.4 Polystyrene (PS)

Polystyrene, commonly known as PS, is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. It was first discovered in 1839 by Eduard Simon and has since been commercialized for various applications due to its versatility and ease of processing.

PS is available in several forms, including solid and foam, and is characterized by its rigidity, clarity, and excellent insulation properties. It is widely used in the production of disposable cutlery, plastic models, CD and DVD cases, and various packaging materials.

Expanded polystyrene (EPS) foam is notably used for insulation and cushioning in packaging. PS is valued for its affordability and ease of fabrication, making it a common choice in both consumer and industrial products.

3. Manufacturing Processes for Plastic Conduits

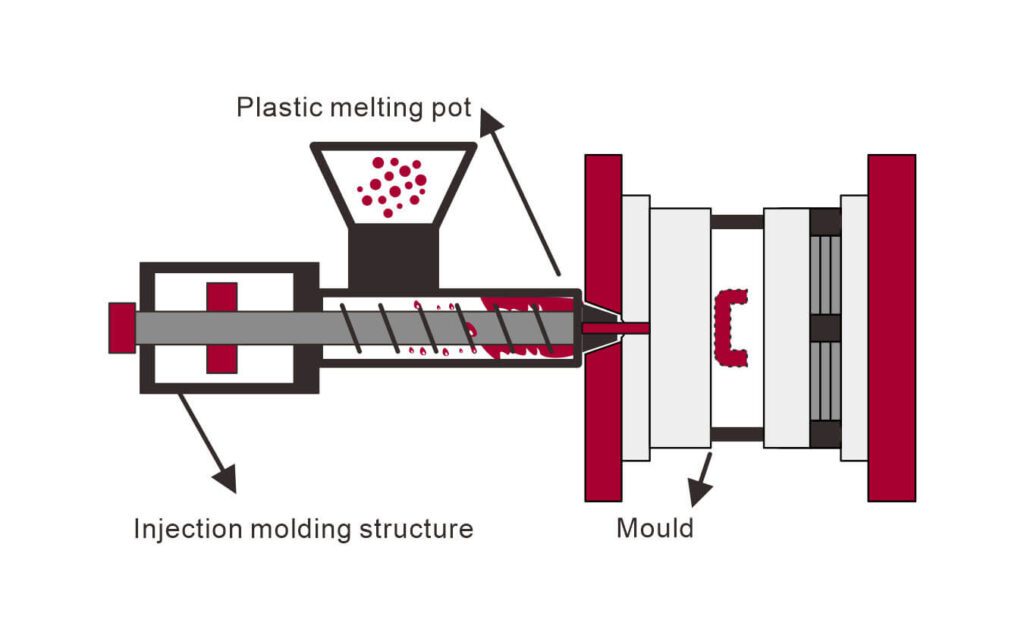

3.1 Injection Molding

Injection molding is a widely used manufacturing process for producing plastic conduits with high precision and complex geometries. Here’s a detailed breakdown of the process:

– Material Preparation: The process begins with the preparation of plastic pellets, which are typically made from thermoplastics like Polyvinyl Chloride (PVC), Polypropylene (PP), or Polyethylene (PE). These pellets may be pre-blended with additives to enhance specific properties, such as flame retardants, colorants, or stabilizers.

– Melting: The pellets are fed into a hopper that leads to the injection molding machine’s barrel. Inside the barrel, the pellets are subjected to heat from electric heaters and mechanical shear from a rotating screw. The temperature and shear force cause the pellets to melt into a homogeneous molten plastic. The precise temperature control is crucial to ensure the plastic reaches the right viscosity for injection.

– Injection: Once the plastic is molten, it is forced into a mold cavity under high pressure through a nozzle. The mold, which is made from metal, is designed with the exact shape and dimensions of the desired conduit. Injection pressures can vary but are typically high to ensure the molten plastic fills every part of the mold and eliminates air pockets. This step ensures the conduit’s final shape is accurately replicated from the mold.

– Cooling: After the mold is filled, the plastic is allowed to cool and solidify. The cooling time is critical as it affects the conduit’s final properties. The mold is often equipped with cooling channels through which water or coolant circulates to expedite the cooling process. The solidified conduit retains the shape of the mold and gains strength.

– Ejection: Once the plastic has cooled and solidified sufficiently, the mold is opened, and the conduit is ejected. Ejection pins or mechanical arms are used to remove the finished product from the mold. Any excess material, such as runners and sprues, which were used to direct the molten plastic into the mold, is trimmed off.

– Finishing: The final product undergoes additional finishing processes, which may include trimming, surface polishing, and quality inspections. Any defects are corrected, and the conduits are checked to ensure they meet industry standards and specifications. For certain applications, additional post-molding processes such as printing or coating may be applied.

Applications: Injection molding is ideal for producing high-volume, complex plastic conduits with tight tolerances. It is commonly used for manufacturing conduits with specific design features, such as ribbed surfaces or integrated fittings, which are essential for various electrical, plumbing, and industrial applications.

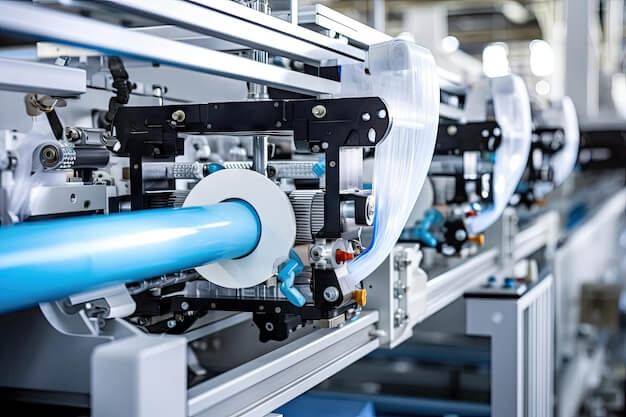

3.2 Extrusion

Extrusion is a continuous process used to produce long sections of plastic conduits with uniform cross-sectional profiles. Here’s a detailed breakdown of the extrusion process:

– Material Preparation: Like injection molding, extrusion starts with plastic pellets made from materials such as PVC, PE, or PP. These pellets are often mixed with additives to achieve desired properties, such as UV resistance, color, or enhanced mechanical strength.

– Melting: The pellets are fed into the hopper of the extruder. Inside the extruder, the pellets are conveyed through a heated barrel where they are subjected to mechanical shear from a rotating screw. The combination of heat and shear forces melts the plastic into a homogeneous molten state. Temperature control is essential to maintain the correct viscosity for extrusion.

– Extruding: The molten plastic is forced through a die, which shapes it into a continuous profile. The die is designed with the exact cross-sectional shape of the conduit, whether it is circular, square, or any other profile. The extrusion process is continuous, meaning that long lengths of conduit are produced as the molten plastic flows through the die.

– Cooling: After the plastic exits the die, it is cooled to solidify its shape. Cooling can be done using a water bath, air cooling, or a combination of both. The cooling system ensures that the conduit retains its shape and dimensional stability as it solidifies.

– Cutting: Once the conduit has cooled and solidified, it is cut into specified lengths. Cutting can be done using various methods, such as rotary saws, guillotine cutters, or other automated cutting systems. The length and accuracy of cutting depend on the specific requirements of the application.

– Finishing: The cut sections of conduit are inspected for quality and consistency. Any surface defects or dimensional deviations are corrected. Additional finishing processes may include surface treatments, such as polishing or coating, to meet the desired specifications.

Applications: Extrusion is ideal for producing long, continuous sections of plastic conduit with consistent cross-sectional profiles. It is commonly used for manufacturing standard-sized conduits for electrical wiring, plumbing systems, and industrial applications where uniformity and cost-efficiency are important.

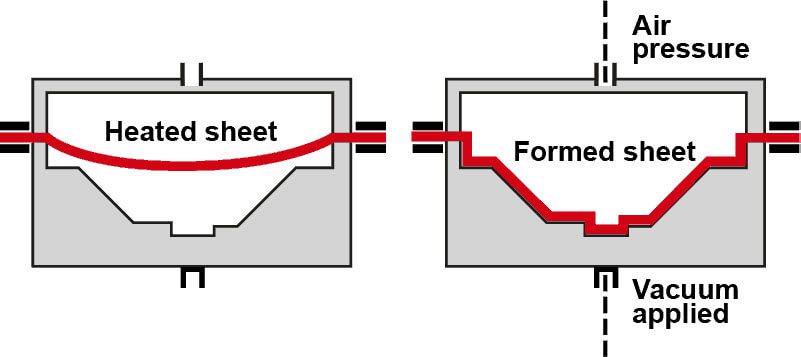

3.3 Thermoforming

Thermoforming is a process used to shape plastic sheets into complex shapes and is less commonly used for standard plastic conduit production but is valuable for specialized applications. This technique involves heating a plastic sheet until it becomes pliable and then forming it over a mold to create custom or intricate designs.

– Heating: The process begins with a flat plastic sheet, which is heated in an oven or other heating apparatus until it reaches a pliable, softened state. The temperature must be carefully controlled to ensure that the sheet becomes uniformly soft and flexible without reaching its melting point.

– Forming: Once the plastic sheet is heated, it is draped over or into a mold. The mold, which can be designed with detailed and complex shapes, determines the final form of the conduit. The heated sheet is then subjected to pressure or vacuum to ensure it conforms to the mold’s contours. This is often done using a vacuum forming machine, where a vacuum pulls the sheet tightly against the mold, or through pressure forming, where air pressure is used to push the sheet into the mold.

– Cooling: After the plastic sheet has been formed around the mold, it is allowed to cool and solidify. Cooling must be done slowly and evenly to ensure that the plastic retains the shape of the mold and does not warp or deform.

– Ejection: Once the plastic has cooled and hardened, the mold is removed, and the formed conduit is taken out. The excess plastic, known as flash, may be trimmed away to achieve the final shape.

– Finishing: The finished conduit may require additional processing to trim, polish, or modify the surface. Any defects or imperfections are corrected, and the final product is inspected to ensure it meets quality standards and specifications.

– Applications: Thermoforming is particularly suited for creating conduits with intricate shapes or custom designs that are not feasible with other methods like injection molding or extrusion. It is used for applications where the conduit needs to have unique geometrical features or specific design elements. While less common for standard conduit production, it is valuable for producing specialized or custom conduits in various industries, including electrical and plumbing systems.

4. Common Types of Plastic Conduits

4.1 Rigid PVC Conduit

Rigid PVC conduit is perhaps the most widely recognized and used type of plastic conduit. Known for its robustness and durability, rigid PVC conduit is ideal for both indoor and outdoor applications. It is highly resistant to corrosion and chemical exposure, ensuring long-term performance even in harsh environments. Its strength makes it suitable for use in residential, commercial, and industrial settings where it protects electrical wiring from physical damage.

Additionally, rigid PVC conduit is relatively easy to install, and its joints can be securely connected using solvent cement, providing a seamless and waterproof seal. The smooth interior surface of rigid PVC conduit allows for easy pulling of wires, reducing the risk of damage during installation. It is also flame-retardant, adding an extra layer of safety in fire-prone areas.

4.2 Electrical Nonmetallic Tubing (ENT)

Electrical Nonmetallic Tubing (ENT) is another commonly used plastic conduit, known for its lightweight and flexible nature. ENT is particularly advantageous in residential and commercial buildings where it can be easily routed through walls, floors, and ceilings. Its flexibility allows for quick installation, especially in retrofit projects where running new conduit through existing structures can be challenging.

ENT is typically used for low-voltage wiring and is valued for its ease of handling and installation, which reduces labor costs and installation time. ENT is often color-coded to indicate different types of wiring, such as electrical, telecommunications, or fire alarm systems, making it easier to identify and manage different systems within a building. It is also compatible with various fittings and connectors, enhancing its versatility in complex installations.

4.3 Liquid-tight Flexible Nonmetallic Conduit

Liquid-tight flexible nonmetallic conduit is designed for use in environments where moisture or liquids are present. This type of conduit combines the flexibility of standard flexible conduits with a liquid-tight construction, making it ideal for outdoor and industrial applications where water resistance is critical. It is commonly used to protect wiring in areas exposed to weather, such as outdoor lighting, or in industrial settings where washdowns and high humidity are factors.

Liquid-tight flexible conduit is constructed with a plasticized PVC jacket over a flexible metal core, providing both flexibility and robust protection against water ingress. It is often used in applications such as air conditioning units, refrigeration equipment, and marine environments where water-tight integrity is paramount.

The conduit can be used with liquid-tight fittings to ensure a completely sealed system, further enhancing its protective capabilities.

4.4 High-Density Polyethylene (HDPE) Conduit

High-Density Polyethylene (HDPE) conduit is known for its high density and strength, making it suitable for underground and outdoor installations. HDPE conduit is highly resistant to impacts and chemicals, ensuring long-term durability even in the most demanding environments. Its flexibility allows for easy installation in trenchless applications, such as horizontal directional drilling.

HDPE conduit is widely used in telecommunications and utility applications, where it provides reliable protection for fiber optic cables and other critical infrastructure. The smooth interior of HDPE conduit reduces friction, making it easier to pull cables through long runs. It is also UV-resistant, making it suitable for above-ground installations where exposure to sunlight is a concern.

HDPE conduit can be manufactured in various diameters and wall thicknesses to meet specific project requirements, and it is often supplied in long coils to minimize joints and connections in the field.

5. Accessories Related to Plastic Conduits

5.1 Couplings

Couplings are essential components used to join two sections of conduit together, ensuring a continuous and secure path for electrical cables. They play a crucial role in extending conduit runs and maintaining system integrity. Generally have rigid conduit and corrugated conduit couplings.

5.2 Elbows

Elbows are fittings that allow the conduit to make different angle turns, which is crucial for navigating around obstacles or corners in the conduit path. Common types of elbows include 90-Degree, and 45-Degree. Many manufacturers like Ctube is available in other angles to fit specific installation needs, providing flexibility in conduit routing for unique or complex pathways.

5.3 Tee Connectors

Tee connectors facilitate the branching of conduit systems in three directions, creating a T-shaped junction. This is particularly useful in complex wiring systems where multiple pathways are required. Tee connectors help organize and distribute cables efficiently within a conduit network.

5.4 Male Adapters

Male adapters are fittings that connect PVC conduit to threaded fittings or electrical boxes, providing a secure transition point. They ensure a stable and reliable connection, preventing any movement or disconnection of the conduit from the electrical box or other threaded components. This stability is crucial for maintaining the integrity of the electrical system.

5.5 Straps and Clamps

Straps and clamps are used to hold the conduit in place, ensuring it remains secure and properly aligned along its path. They are available in various sizes to accommodate different conduit diameters and types.

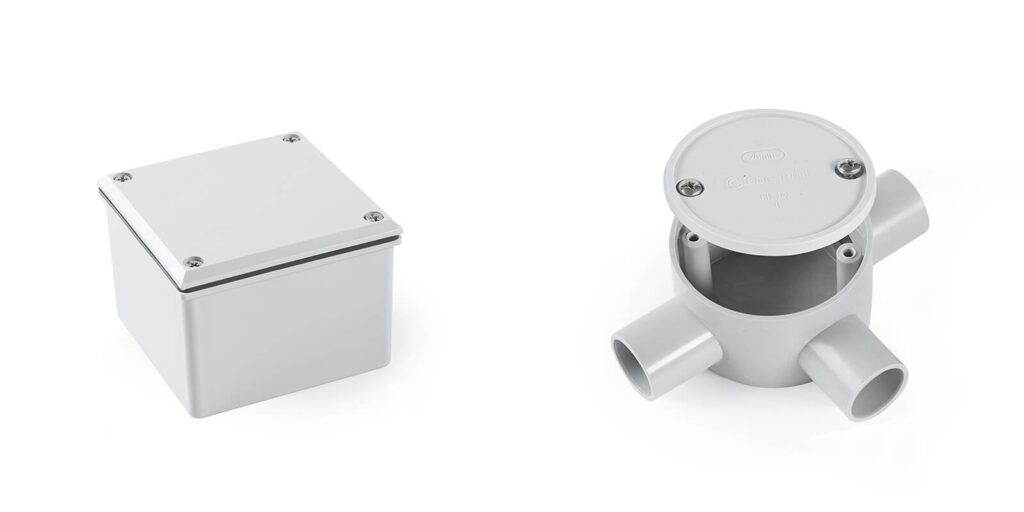

5.6 Electrical Boxes

Electrical boxes, including junction boxes and adaptable boxes, are essential for housing electrical connections and providing protection. They serve as critical components in conduit systems by organizing and securing wiring connections. Types of electrical boxes include:

– Junction Boxes: Used for joining multiple conduits and housing wire splices, junction boxes protect connections from external damage and provide a secure enclosure. They are typically used in both residential and commercial applications to manage complex wiring networks.

– Adaptable Boxes: These offer flexibility in wiring installations, allowing for various configurations and future modifications. They are designed to accommodate different conduit sizes and types, making them versatile for many applications. Adaptable boxes are particularly useful in industrial settings where wiring configurations may change frequently.

6. A Step-by-Step Guide to Connecting Plastic Conduit Fittings

6.1 Tools and Materials Required

– Conduit and fittings

– Hacksaw or conduit cutter

– Deburring tool

– Measuring tape

– Level

– Marker

– Solvent cement

6.2 Preparation

1. Measure and Mark: Measure the required lengths of conduit and mark where cuts will be made.

2. Cut the Conduit: Use a hacksaw or conduit cutter to cut the conduit to the desired lengths.

3. Deburr the Edges: Remove any sharp edges or burrs using a deburring tool to ensure smooth connections.

4. Connecting Conduit Fittings

6.3 Connect Conduit and Fittings

1. Clean the Ends: Wipe the ends of the conduit and the inside of the fittings with a clean cloth.

2. Apply Primer (if required): Some PVC conduit systems require a primer before applying solvent cement. Check the manufacturer’s instructions.

3. Apply Solvent Cement: Apply a thin layer of solvent cement to the outside of the conduit end and the inside of the fitting.

4. Join the Pieces: Quickly insert the conduit into the fitting, giving it a quarter turn to evenly distribute the cement.

5. Hold in Place: Hold the connection for a few seconds to ensure it sets properly.

6.4 Common Mistakes to Avoid

– Improper Cutting: Uneven or rough cuts can lead to poor connections.

– Insufficient Cleaning: Dirt or debris can weaken the bond between conduit and fittings.

– Overtightening: Overly tight connections can damage fittings or conduit.

– Neglecting Alignment: Misaligned conduit can cause issues during wire pulling and compromise system integrity.

7. Applications of Plastic Conduits

7.1 Residential Applications

Plastic conduits are widely used in residential settings due to their safety, efficiency, and ease of installation. In homes, they are employed for both indoor and outdoor wiring, providing a robust pathway that protects electrical cables from physical damage, moisture, and exposure to various elements. Inside the house, plastic conduits are commonly routed through walls, ceilings, and floors, ensuring that the electrical wiring remains intact and insulated. They are particularly beneficial in new constructions and renovations where the conduits can be easily integrated into the building framework.

For outdoor applications, such as garden lighting, external power outlets, and swimming pool wiring, plastic conduits offer excellent resistance to weather conditions, preventing deterioration due to UV rays, rain, and temperature fluctuations. Additionally, their non-conductive nature adds an extra layer of safety by reducing the risk of electrical shocks.

7.2 Commercial Applications

In commercial settings, plastic conduits play a crucial role in managing complex wiring systems required in office buildings, shopping centers, hospitals, and educational institutions. These environments often involve extensive and intricate electrical networks that need reliable protection and organization.

Plastic conduits provide the necessary flexibility and durability to accommodate these needs, allowing for efficient routing of electrical cables through walls, ceilings, and under floors. They help in maintaining a neat and orderly installation, which is essential for both safety and maintenance purposes.

In office buildings, for instance, plastic conduits are used to manage the extensive cabling for computer networks, lighting, and HVAC systems. Their ease of installation and adaptability to tight spaces make them an ideal choice for retrofitting older buildings where space constraints can pose significant challenges. Furthermore, plastic conduits are resistant to fire and chemical exposure, adding an extra layer of protection in environments such as hospitals and laboratories where safety standards are stringent.

7.3 Industrial Applications

Industrial environments pose unique challenges due to the harsh conditions often present, such as exposure to chemicals, extreme temperatures, and mechanical wear. Plastic conduits are well-suited for these demanding settings, providing robust protection for electrical wiring in factories, warehouses, and manufacturing plants. Their resistance to chemicals and moisture ensures that the wiring remains safe from corrosive substances commonly found in industrial processes.

Additionally, plastic conduits can withstand significant physical impacts, safeguarding the cables from accidental damage caused by heavy machinery or equipment. In factories, they are used to route power and control cables to various machines and production lines, ensuring a reliable and uninterrupted power supply.

The flexibility of plastic conduits also allows for easy modifications and expansions of the electrical system as the industrial setup evolves. In warehouses, plastic conduits help in organizing and protecting the extensive wiring required for lighting, security systems, and automated inventory systems.

7.4 Specialty Applications

Plastic conduits are also utilized in specialty applications where their unique properties offer significant advantages. For instance, in solar panel installations, plastic conduits provide a durable and weather-resistant pathway for the electrical cables connecting the panels to the inverter and the electrical grid. Their resistance to UV radiation and harsh weather conditions ensures long-term reliability and safety.

Additionally, plastic conduits are often used in underground wiring applications, such as in the installation of buried electrical cables for street lighting, telecommunications, and power distribution networks. Their resistance to moisture and corrosion makes them ideal for these applications, ensuring that the electrical system remains protected even in challenging underground environments.

Another specialty application includes the use of plastic conduits in marine and coastal installations, where exposure to saltwater and high humidity can quickly degrade other materials. The non-corrosive nature of plastic conduits makes them an excellent choice for these environments, providing reliable protection for electrical wiring in boats, docks, and coastal facilities.

8. Standards and Certification Requirements

Ensuring the safety, reliability, and performance of plastic conduits involves adhering to various standards and certifications. These standards, set by different organizations worldwide, specify requirements for manufacturing, testing, and installing plastic conduits, ensuring they meet stringent quality and safety criteria. Ctube’s PVC conduit and fittings comply wite the following relevant certifications.

8.1 UL (Underwriters Laboratories) Listings

The UL (Underwriters Laboratories) listings are crucial in the United States for confirming that plastic conduits meet the highest safety and performance standards. UL standards cover a wide range of criteria, including flame resistance, impact resistance, and electrical insulation properties. Products that pass these rigorous tests are marked with the UL label, indicating compliance with critical safety standards. This certification is particularly important for applications in both residential and commercial buildings where safety is paramount. UL-listed conduits are required to withstand specific fire conditions, resist mechanical impacts, and provide adequate insulation to prevent electrical faults and short circuits.

8.2 ASTM (American Society for Testing and Materials) Standards

ASTM standards are internationally recognized benchmarks for the testing methods and performance criteria of plastic conduits. These standards ensure that conduits meet specific quality and safety requirements, including material composition, mechanical properties such as tensile strength and flexibility, and environmental resistance to UV radiation, moisture, and temperature fluctuations. Compliance with ASTM standards ensures that plastic conduits are durable, reliable, and suitable for their intended applications. ASTM standards are widely followed in the United States and often referenced globally for quality assurance.

8.3 NEC (National Electrical Code) Compliance

The NEC (National Electrical Code) provides comprehensive guidelines for the safe installation and use of electrical conduits in the United States. Compliance with NEC standards ensures that plastic conduits are installed correctly and safely, addressing various aspects such as installation practices, wiring methods, and protection and support for the conduits. Following NEC standards is mandatory in many U.S. jurisdictions and ensures that electrical installations are safe, efficient, and compliant with local building codes. The NEC is frequently updated to reflect the latest in safety and technology, making adherence to its guidelines crucial for modern electrical installations.

8.4 IEC (International Electrotechnical Commission) Standards

IEC standards provide global guidelines for the performance and safety of plastic conduits, facilitating international trade and ensuring that products meet consistent quality benchmarks worldwide. These standards cover safety requirements, performance criteria, and compatibility and interoperability with electrical systems and components used in different countries. Adherence to IEC standards is essential for manufacturers looking to market their products internationally, as it ensures their conduits are accepted in a wide range of countries, including those in Europe, Asia, and South America. IEC standards focus on ensuring that conduits provide adequate insulation, resist fire and mechanical impacts, and perform reliably under various environmental conditions.

8.5 CSA (Canadian Standards Association) Certification

CSA certification is a key standard in Canada, similar to UL certification in the United States. It ensures that plastic conduits meet stringent safety and performance standards, including electrical safety, flame retardancy, and mechanical durability. Products with CSA certification are recognized for their quality and safety, making them a preferred choice in the Canadian market. CSA-certified conduits must demonstrate resistance to ignition and fire spread, maintain integrity under mechanical stress, and provide effective insulation to safeguard electrical systems.

8.6 Country-Specific Applications and Requirements

United States: Primarily follows UL, NEC, and ASTM standards. Conduits must meet stringent fire safety, impact resistance, and electrical insulation criteria.

Canada: Adheres to CSA standards, which ensure high levels of fire safety, mechanical durability, and electrical insulation.

European Union: Follows IEC standards and additional EU-specific regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), which ensure that conduits are free from harmful substances and safe for human health and the environment.

Australia/New Zealand: Compliance with AS/NZS standards, which align closely with IEC standards, ensuring international compatibility and safety.

Asia: Countries like China and India often adopt IEC standards along with local regulatory requirements, ensuring compatibility with global markets while addressing regional safety concerns.

9. Benefits of Using Plastic Conduits

9.1 Durability and Longevity

Corrosion Resistance: One of the standout benefits of plastic conduits is their resistance to corrosion. Unlike metal conduits, plastic conduits do not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This makes them an excellent choice for outdoor installations, underground applications, and environments with high humidity or exposure to chemicals, such as agricultural settings and chemical plants.

Flexibility and Impact Resistance: Plastic conduits are inherently more flexible than metal conduits, which allows them to absorb impacts and resist cracking or breaking. This flexibility makes them particularly useful in applications where the conduit might be subject to movement or vibration, such as in machinery or seismic zones. Additionally, their impact resistance ensures that they maintain their integrity even when subjected to physical stress.

9.2 Cost Considerations

Lower Material Cost: The cost of raw materials and manufacturing processes for plastic conduits is generally lower than for metal conduits. This results in a more affordable option for many projects, especially those with budget constraints.

Reduced Installation Costs: Due to their lightweight nature, plastic conduits are easier to handle, transport, and install, reducing labor costs significantly. They do not require specialized tools for cutting or joining, which simplifies the installation process and further cuts down on expenses.

9.3 Installation Ease

Lightweight and Easy to Handle: The lightweight nature of plastic conduits makes them much easier to transport, handle, and install compared to metal conduits. This ease of use is particularly beneficial in large-scale installations or in areas that are difficult to access.

Simplified Cutting and Joining: Plastic conduits can be easily cut with basic tools, and joining them typically involves solvent cement or simple connectors. This straightforward installation process can save time and reduce the need for specialized labor.

9.4 Environmental Impact

Non-Reactive and Recyclable: Many plastic conduits are made from recyclable materials and do not release harmful substances into the environment. Advances in plastic technology, such as the development of low smoke halogen-free (LSZH) conduits, have made plastic conduits an environmentally friendly option that emits fewer toxic gases in the event of a fire.

Energy Efficiency in Production: The manufacturing process for plastic conduits typically requires less energy compared to metal conduits, resulting in a lower carbon footprint. This makes plastic conduits a more sustainable choice in terms of energy consumption.

9.5 Specific Use Cases

Residential and Commercial Applications: Plastic conduits are widely used in residential and commercial settings due to their cost-effectiveness, ease of installation, and adequate protection for general electrical wiring needs. They are suitable for running wiring through walls, ceilings, and floors in homes, offices, and retail spaces.

Underground and Outdoor Installations: The resistance to moisture and corrosion makes plastic conduits an excellent choice for underground and outdoor applications, such as running electrical wiring to outdoor lighting, garden features, and outbuildings.

10. PVC Conduit vs Metal Conduit vs Fiberglass Conduit

10.1 NECA Labor Installation Rates

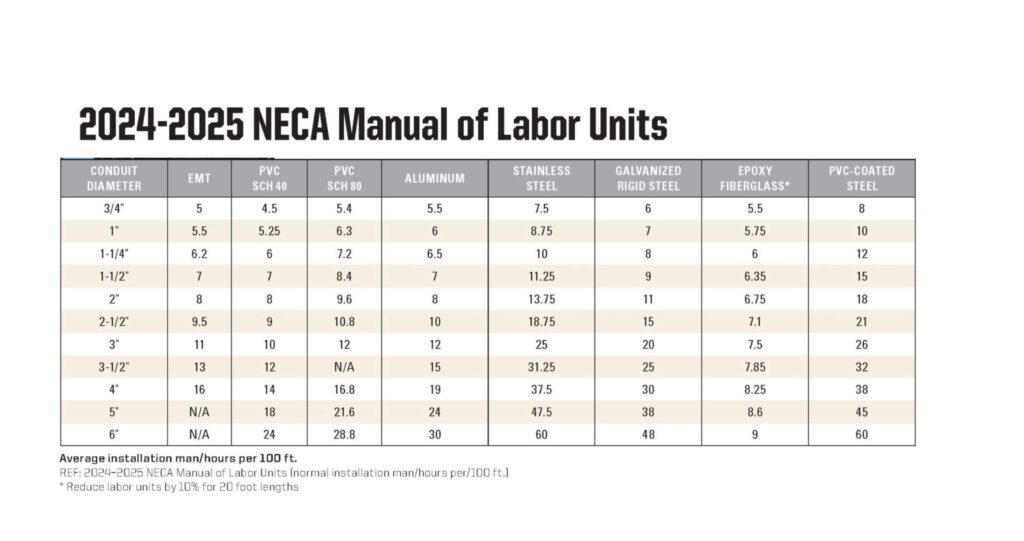

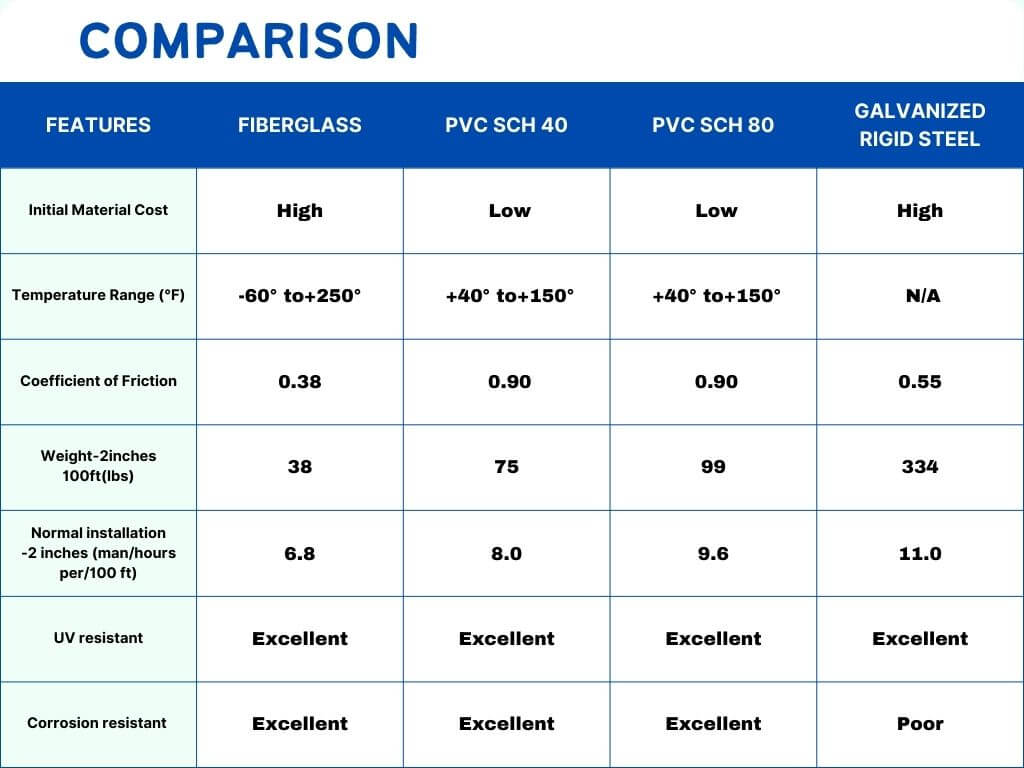

The variability in labor requirements depends on the conduit material and size. Conduits made of different materials have different installation difficulties and take different amounts of time at the same size and length, as shown in the data in the table above.

From the 2024-2025 NECA Manual of Labor Units, detailing the average installation man/hours required per 100 feet for various types of conduit materials. The materials listed include EMT, PVC SCH 40, PVC SCH 80, Aluminum, Stainless Steel, Galvanized Rigid Steel, Fiberglass, and PVC-Coated Steel.

For example, installing 100 feet of 2 inches stainless steel conduit takes 13.75 man/hours, whereas the same size PVC SCH 40 conduit requires only 8 man/hours.

10.2 Weight Comparison

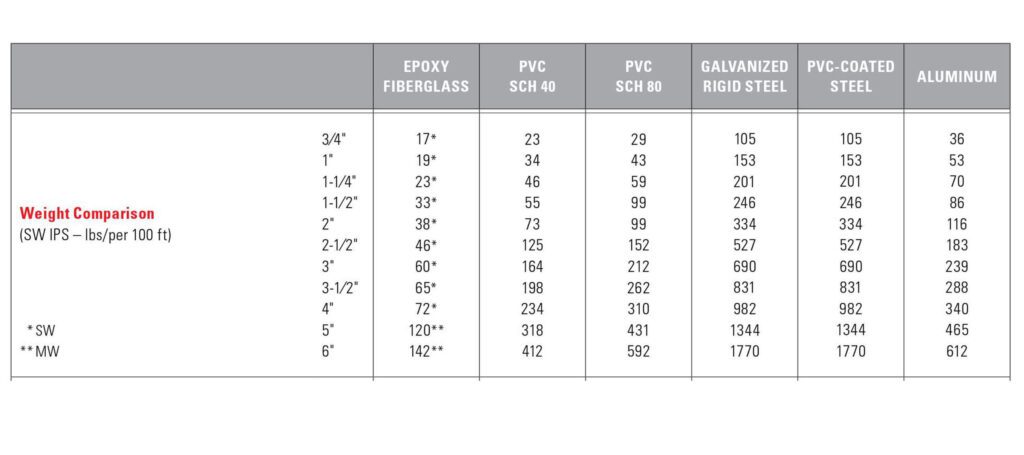

The above table outlines the weight in pounds per 100 feet for various conduit materials and compares the weights of Epoxy Fiberglass, PVC SCH 40, PVC SCH 80, Galvanized Rigid Steel, PVC-Coated Steel, and Aluminum across different conduit diameters, ranging from 3/4″ to 6″.

For instance, a 3/4″ Epoxy Fiberglass conduit weighs 17 pounds per 100 feet, while a 3/4″ PVC SCH 40 weighs 23 pounds, and the same size in Galvanized Rigid Steel weighs 105 pounds. This trend is consistent across other sizes, with Galvanized Rigid Steel generally being the heaviest and PVC SCH 40 among the lighter materials.

This comparison provides a clear understanding of the weight differences between various materials and conduit sizes.

10.3 PVC Conduit, Metal Conduit and Fiberglass Conduit Comparison Parameters

Through some data comparison of different materials, we selected fiberglass conduit, PVC conduit, and kinds of mental conduit with the same size of 2 inches and the same length of 100 feet for brief comparison.

The above table provides some reference by comparing weight, price, installation time, friction coefficient, temperature range, pressure resistance, UV rays, etc. Choosing the right conduit involves considering the specific needs of your project. Each type has its unique advantages and should be selected based on the requirements of the installation environment.

11. Conclusion

11.1 Choose the Right Conduit

In conclusion, plastic conduits offer a range of benefits and applications that make them a valuable choice for various electrical and communication projects. From the versatility and ease of installation of PVC conduit to the moisture resistance and flexibility of Liquid-tight Flexible Nonmetallic Conduit, and the durability and impact resistance of HDPE conduit, each type serves distinct needs effectively. Understanding the specific characteristics and advantages of these conduits allows for informed decision-making, ensuring optimal performance and protection for your wiring systems.

As technology and construction practices evolve, the continued development of plastic conduit materials and manufacturing processes will likely enhance their performance and applications further. By staying informed about these advancements and choosing the right conduit for your project, you can achieve reliable, safe, and efficient results in your electrical and communication infrastructure.

11.2 Ctube’s PVC Conduit and Fittings

At Ctube, we are dedicated to innovation and continually improving our product range. We provide high-quality PVC conduit and fittings, which have passed relevant tests and standards to ensure the efficiency and safety of electrical installations.

Beyond our standard PVC conduit offerings, we have expanded our portfolio to include specialized lines such as the photovoltaic solar series and the low-smoke halogen-free series.

Our conduits are widely used in various electrical installation projects and have received acclaim from numerous satisfied customers. If you have any project requirements or need additional information, please do not hesitate to contact us.

FAQs

1.Can plastic conduit be used for outdoor installations?

Yes, plastic conduits can be used outdoors. They are resistant to moisture, UV rays, and many chemicals, making them suitable for outdoor applications such as garden lighting, outdoor electrical installations, and underground wiring.

2.What is the difference between uPVC and PVC conduits?

Polyvinyl chloride (PVC) is the world’s third-most widely manufactured artificial plastic polymer. It is a flexible type of plastic used in producing various construction materials.

In contrast, unplasticised polyvinyl chloride (uPVC) is a material without the plasticisers BPA and phthalates found in PVC, the two components responsible for its flexibility.

3.What’s the difference among conduits of PVC, LFNC , and HDPE?

PVC conduit is rigid and made from polyvinyl chloride, commonly used in residential and commercial wiring for both indoor and outdoor applications.

Liquid-tight Flexible Nonmetallic Conduit, made from flexible PVC, is designed to be liquid-tight and is ideal for environments needing moisture and chemical resistance.

HDPE conduit, made from high-density polyethylene, is rigid and often used in underground installations, telecommunications, and electrical power distribution. It is installed using trenching or directional boring and joined with heat fusion or mechanical fittings.