Table of Contents

Toggle1. Introduction

Electrical conduits are the unsung heroes of safe wiring systems, shielding wires from damage, moisture, and fire hazards. Yet, for DIY enthusiasts, what seems like a straightforward task—installing conduits—can quickly spiral into a dangerous game of trial and error. A single misstep, like using the wrong material or overstuffing a conduit, can lead to code violations, costly repairs, or even catastrophic failures.

This guide identifies the top five conduit mistakes that plague DIY projects—errors rooted in material mismatches, poor bending techniques, inadequate support, overfilling, and faulty fittings. And we hope this information helpful. Electricity demands respect. Always double-check local codes, wear protective gear, and when in doubt, consult a licensed electrician.

2. Choosing the Wrong Conduit Material

Electrical conduits serve as protective armor for wiring, shielding it from physical damage, moisture, and environmental hazards. However, selecting the wrong material can undermine this protection, leading to corrosion, insulation failure, and even fire.

This chapter dissects the nuances of conduit materials, environmental compatibility, and code compliance to ensure your installation withstands time and conditions.

2.1 Using Plumbing PVC Instead of Electrical PVC

A frequent mistake DIYers make is assuming plumbing PVC and electrical PVC conduits are interchangeable. Though both are made from polyvinyl chloride, they are engineered for vastly different applications. Plumbing PVC is designed to handle pressurized water systems, while electrical PVC is manufactured to protect wiring from physical damage, UV exposure, and fire hazards. Using plumbing PVC for electrical work violates code standards and creates significant safety risks.

2.1.1 Durability and UV Resistance

Electrical PVC conduit is fortified with additives to withstand mechanical stress and environmental challenges. For example, Schedule 40 and Schedule 80 electrical PVC are UV-stabilized and heat-resistant, making them suitable for outdoor installations. In contrast, plumbing PVC lacks these protective additives. When exposed to sunlight or temperature fluctuations, it becomes brittle, cracks easily, and fails to shield wires from damage. This makes plumbing PVC a poor choice for above-ground electrical runs or outdoor projects.

2.1.2 Color Coding and Markings

Visual distinctions help differentiate the two types. Electrical PVC is typically gray and labeled with standards like “UL 651” or “NEC-rated,” ensuring compliance with electrical codes. Plumbing PVC, on the other hand, is usually white or cream-colored and marked with “NSF-PW” (indicating suitability for potable water). These markings are critical for inspectors and installers to verify the correct conduit type.

2.1.3 Fire Safety

Electrical PVC is formulated to resist flames and limit toxic smoke production during a fire. Plumbing PVC, however, melts at high temperatures, exposing wires and releasing hazardous fumes. This difference is especially critical in enclosed spaces, where toxic smoke from burning plumbing PVC could endanger occupants.

2.2 The Wrong Mix of Conduit Materials

Mixing metal and plastic conduits can work well if done correctly, but improper mixing can create mechanical stress, grounding issues, and corrosion. Understanding how to combine different materials is key to a safe and durable installation.

2.2.1 Electrical Grounding Issues

Metal conduits, such as galvanized steel and aluminum, are conductive and provide a grounding path to protect against electrical faults. Plastic conduits like PVC are non-conductive and cannot carry current for grounding. If a metal conduit is connected to a plastic conduit without a grounding bushing or transition fitting, the electrical continuity is broken, increasing the risk of electric shock or fire. Use transition fittings with grounding lugs to maintain a consistent ground path.

2.2.2 Thermal Expansion and Contraction

Metal and plastic conduits expand and contract at different rates when exposed to temperature changes. Metal expands minimally, while plastic expands more significantly. This difference can cause stress at the connection points, leading to cracks or conduit separation over time. Installing flexible expansion couplings at transition points allows the conduits to move independently and prevents joint damage.

2.2.3 Corrosion and Galvanic Reaction

When different metals, like steel and aluminum, are connected without insulation, galvanic corrosion can occur due to the electrochemical reaction between dissimilar metals. Over time, this weakens the conduit and can cause connection failure. Transition fittings with rubber or plastic sleeves create a barrier between metals, preventing corrosion and moisture infiltration.

2.3 Using the Wrong Type of Conduit for the Installation Environment

Selecting the wrong type of conduit for the installation environment can lead to premature failure, safety hazards, and costly repairs. Conduits are designed to handle specific environmental factors like moisture, heat, UV exposure, and mechanical stress. Using a conduit not rated for the environment can result in cracking, corrosion, and electrical faults.

2.3.1 Indoor vs. Outdoor Applications

For indoor installations, PVC and ENT (Electrical Non-metallic Tubing) are lightweight and resistant to corrosion, making them ideal for residential and commercial use. However, PVC conduits used outdoors must be rated for UV exposure and high temperatures to prevent degradation. For outdoor or exposed installations, rigid metal conduit (RMC) and intermediate metal conduit (IMC) are preferred due to their strength and weather resistance.

2.3.2 Wet vs. Dry Locations

Conduits in wet or damp environments must have moisture resistance. Liquid-tight flexible metal conduit (LFMC) and rigid PVC conduit are designed for wet locations because they provide a waterproof barrier and prevent moisture infiltration. Standard EMT (Electrical Metallic Tubing) is not suitable for wet environments unless treated for corrosion resistance. Joints and fittings must be sealed with watertight connectors to prevent moisture ingress.

2.3.3 High-Temperature and Corrosive Environments

Metal conduits like RMC and IMC handle high temperatures better than plastic, making them ideal for industrial applications near heat-generating equipment. However, metal can corrode in chemical-rich or salty environments. In such cases, PVC-coated metal or stainless steel conduit offers better corrosion resistance.

2.3.4 Underground vs. Above-Ground Installations

Underground installations require conduits that resist soil pressure, moisture, and corrosion. Schedule 40 and Schedule 80 PVC conduits are rated for direct burial and provide excellent resistance to moisture and chemicals. Metal conduits installed underground need protective coatings or plastic sleeves to prevent rust and degradation from soil contact.

3. Common Mistakes in Conduit Bending

Conduit bending is more than just shaping a piece of tubing to fit a space. It directly impacts the performance and longevity of the electrical system. Improper bends can cause excessive wear on electrical wires, make it harder to pull conductors through the conduit, and create points of mechanical weakness that can lead to failures over time.

3.1 Over-Bending or Kinking

Over-bending or kinking occurs when a conduit is bent too sharply or forcefully, causing it to collapse or deform. This weakens the conduit’s structure and increases friction when pulling wires, which can damage the wire insulation and lead to electrical faults.

3.1.1 Causes of Over-Bending

Improper use of bending tools is a common cause of over-bending. Applying too much force, using the wrong size bending shoe, or working with damaged tools can cause the conduit to crimp or flatten. For example, rigid metal conduit (RMC) can kink if bent manually without enough leverage, while PVC conduit can crack if not heated properly before bending.

3.1.2 Consequences of Kinking

Kinks and sharp bends create uneven surfaces that make it harder to pull wires through the conduit, increasing the risk of insulation damage and short circuits. In underground or outdoor installations, kinks can trap moisture and debris, accelerating corrosion and weakening the conduit over time.

3.2 Using Incorrect Bend Radius

The bend radius refers to the minimum allowable curve a conduit can make without damaging the conduit or the wires inside. Bending a conduit too tightly can cause structural damage and make it harder to pull wires through, while a bend that’s too wide can lead to sagging and poor wire support.

3.2.1 Problems with a Tight Bend Radius

When the bend radius is too small, the conduit’s inner wall compresses while the outer wall stretches, causing buckling, flattening, or cracks. This increases friction when pulling wires, which can tear or scrape insulation, increasing the risk of short circuits and overheating. Tight bends in metal conduit may also cause the conduit to deform, reducing its internal diameter and obstructing the wire path.

3.2.2 Problems with a Large Bend Radius

An excessively large bend radius increases the overall length of the conduit run, leading to slack and poor support for the wires. Wires may bunch up or create pressure points inside the conduit, increasing resistance and localized heating. Large bends also require more frequent support to prevent sagging over time.

3.3 Misaligned Bends and Poor Angles

Misaligned bends and poor angles occur when conduit sections don’t line up properly, creating stress on joints and fittings. This can lead to weakened connections, moisture ingress, and difficulty pulling wires through the conduit.

3.3.1 Causes of Misalignment

Inaccurate measuring and marking are the main causes of misaligned bends. Even a slight error in a 90-degree bend can prevent the conduit from aligning with connection points, forcing installers to apply pressure to adjust the fit. Using the wrong bending tool or rushing the process can also lead to inconsistent angles.

3.3.2 Consequences of Poor Angles

Misaligned bends create mechanical stress at joints, increasing the risk of cracks and loosening over time. Poor alignment makes wire pulling more difficult and increases friction, which can damage wire insulation. In exposed installations, crooked bends look unprofessional and may fail inspection.

3.4 Wrinkling and Flattening of the Conduit

Wrinkling and flattening occur when a conduit is bent improperly, causing the walls to collapse or buckle. This reduces the internal space for wires and increases friction, which can damage insulation and weaken the conduit’s protective function.

3.4.1 Causes of Wrinkling and Flattening

Wrinkling happens when PVC conduit is overheated or bent unevenly, causing the inner wall to buckle. Flattening often occurs when too much force is applied during bending or when the wrong size bending shoe is used. Metal conduits may flatten if bent with excessive pressure or using a damaged bending tool.

3.4.2 Consequences of Deformed Conduits

Wrinkled or flattened conduits make it harder to pull wires through, increasing friction and the risk of insulation damage. The reduced internal diameter also restricts wire capacity and creates weak points that may crack or fail under stress.

4. Common Mistakes in Conduit Support and Fastening

Improperly supporting or fastening electrical conduit is a common mistake that can lead to system instability, sagging, damage to conductors, and long-term safety hazards. Electrical conduits must be securely anchored and supported to prevent movement, stress on joints, and damage from environmental or mechanical forces. Inadequate support can result in conduit separation, exposure of live wires, increased resistance, and even fire hazards in extreme cases.

4.1 Overlooking Expansion and Contraction

Temperature changes cause conduits to expand and contract. Ignoring this movement can lead to warping, joint separation, and long-term system failure, especially in outdoor installations. PVC conduits expand more than metal, making them more susceptible to damage from thermal stress.

4.1.1 Causes of Expansion and Contraction Issues

PVC expands about 0.36 inches per 10 feet for every 10°F increase, while metal conduits expand much less—about 0.07 inches per 10 feet. If not properly accounted for, this difference can cause stress at joints, leading to cracks, conduit separation, and exposed wires.

4.1.2 Consequences of Thermal Stress

Thermal movement can cause conduits to bow, crack, or pull away from fittings. In outdoor or underground installations, this creates openings for moisture and debris, increasing the risk of corrosion and electrical failure.

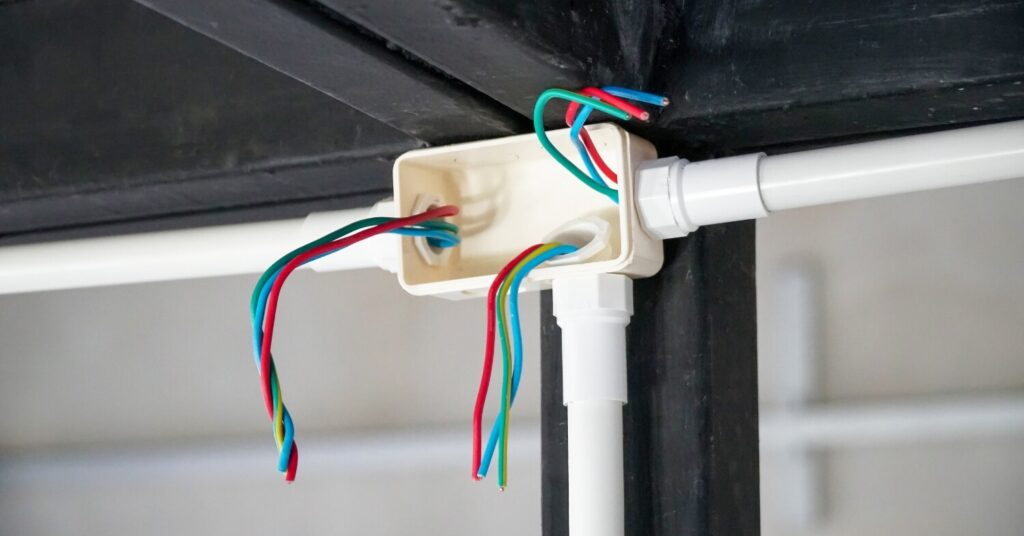

4.2 Improper Installation of Joints and Fittings

Poorly installed joints and fittings can weaken the conduit system, leading to separation, moisture ingress, and exposed wiring. Proper alignment, sealing, and securing of joints are essential for a safe and durable installation.

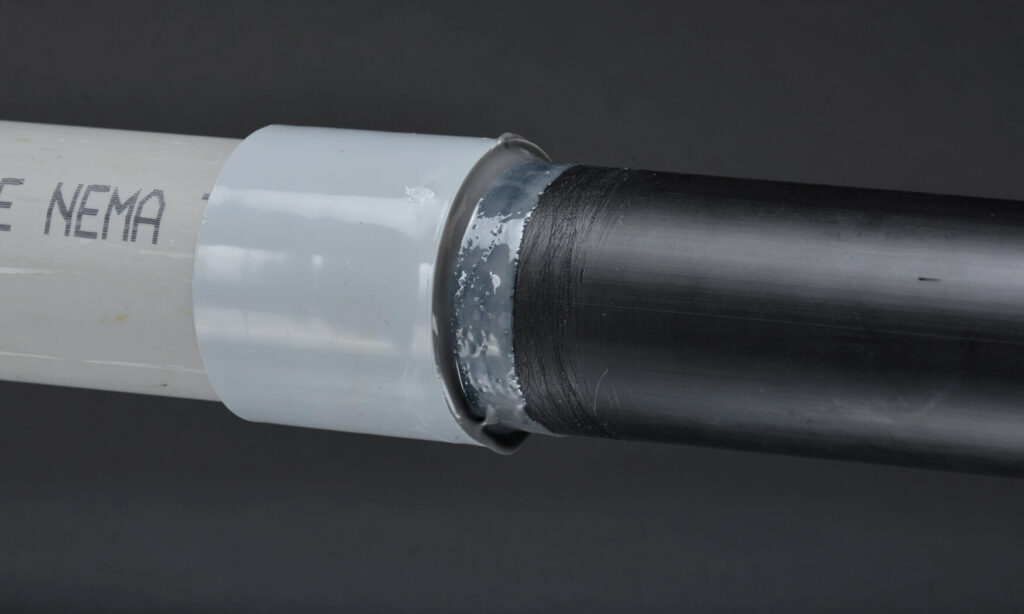

4.2.1 Causes of Improper Installation

Misaligned joints, inadequate cement application, and incorrect fitting size are common issues. For PVC conduit, failing to clean and prime surfaces before applying solvent cement can cause weak bonds. Over-tightening metal fittings or using mismatched connectors can also lead to damage and poor grounding.

4.2.2 Consequences of Poor Joint Installation

Loose or misaligned joints create weak points where moisture and debris can enter, increasing the risk of corrosion and electrical failure. In high-vibration areas, poorly secured joints may loosen over time, exposing wires and creating fire hazards.

4.3 Failing to Follow Proper Support Spacing

Proper support spacing prevents conduits from sagging, separating at joints, and putting stress on the wiring. Following NEC guidelines for support placement is essential for a secure and long-lasting installation.

4.3.1 Causes of Poor Support Spacing

Incorrect spacing between supports is a common mistake. For PVC conduit, NEC Table 352.30 requires supports every 3 feet for conduits up to 1 inch in size and every 5 feet for larger sizes. Metal conduit types, such as EMT and RMC, have different spacing requirements due to their higher strength and rigidity.

4.3.2 Consequences of Poor Support

Without proper support, conduits can sag or pull away from joints, causing misalignment and stress on the wires inside. In outdoor or high-vibration settings, loose conduit may allow moisture and debris to enter the system, leading to corrosion and electrical faults.

5. Common Causes of Conduit Overfilling

Overfilling a conduit is a common mistake that can severely impact the safety and performance of an electrical system. Electrical conduits are designed to protect and organize electrical wiring while providing enough space for proper heat dissipation and flexibility. However, when too many conductors are pulled through a single conduit, several issues can arise, including overheating, increased friction during wire pulling, and difficulty in future maintenance or repairs.

5.1 Misunderstanding Conduit Sizing

Conduit sizing mistakes are common among DIYers, leading to overfilling, overheating, and damaged wires. Conduit size is based on trade size, not internal diameter, which can cause confusion when calculating capacity.

5.1.1 Causes of Sizing Mistakes

DIYers often assume conduit size corresponds to the inner diameter, but this isn’t the case. For example, a 1-inch Schedule 40 PVC conduit has an actual internal diameter of about 1.049 inches. Wall thickness also varies between conduit types (e.g., Schedule 40 vs. Schedule 80), further affecting capacity.

5.1.2 Consequences of Incorrect Sizing

Overfilling a conduit restricts airflow and increases friction during wire pulling, which can damage insulation and cause overheating. Poorly sized conduits also make future modifications difficult and increase the risk of short circuits.

5.2 Adding Too Many Wires After Initial Installation

Adding extra wires to an already installed conduit may seem convenient, but it often leads to overfilling, overheating, and wire damage. Conduits have strict fill limits based on size and wire type, which must be followed to avoid electrical hazards.

5.2.1 Causes of Overfilling

DIYers often exceed NEC’s fill limits when adding extra circuits to an existing conduit. For example, a 1-inch Schedule 40 PVC conduit filled at 35% capacity may exceed the 40% limit by adding just a few more wires. This increases friction and prevents proper heat dissipation.

5.2.2 Consequences of Overfilling

Overfilled conduits restrict airflow, causing heat buildup that weakens wire insulation and increases the risk of short circuits. Overcrowding also makes future maintenance difficult and increases the chance of damaging existing wires during modifications.

5.3 Misjudging Bends and Junction Box Space

Incorrect bend angles and inadequate junction box space can make it harder to pull wires and increase stress on the conduit and fittings. Following NEC guidelines for bends and box fill is essential for a smooth and safe installation.

5.3.1 Causes of Misjudged Bends and Space

DIYers often exceed the NEC’s limit of 360 degrees of total bend between pull points, creating excessive tension on the wires. Undersized junction boxes or overcrowding with too many wires and connectors also create space issues, making installation and future maintenance difficult.

5.3.2 Consequences of Poor Planning

Tight bends increase friction and may damage wire insulation. Overfilled junction boxes make it hard to secure connections properly, increasing the risk of loose wires, short circuits, and overheating.

6. Common Fitting Connection Mistakes

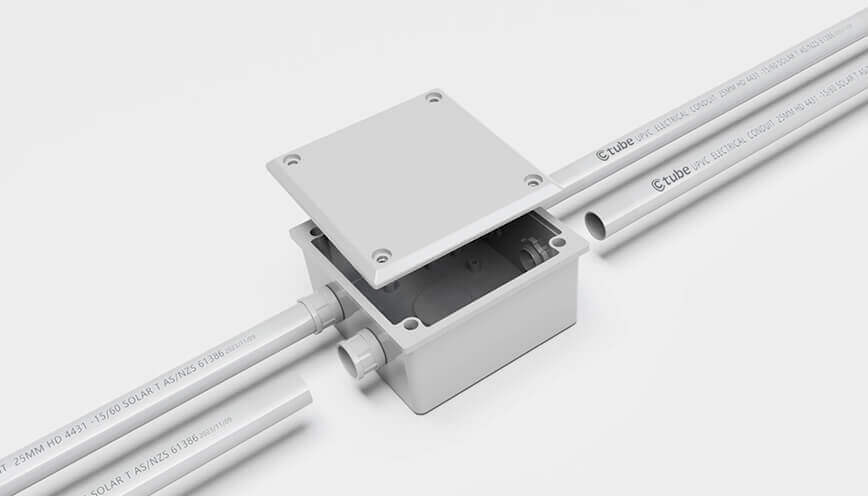

Poorly installed or improperly selected conduit fittings can compromise the integrity of the entire electrical system, leading to moisture intrusion, electrical shorts, and mechanical failure. Properly securing and sealing conduit fittings is critical for maintaining grounding continuity, ensuring weather resistance, and preventing damage to the conductors.

6.1 Choosing the Wrong Type of Fitting

Using the wrong type of conduit fitting can weaken the system, allowing moisture and debris to enter and compromising electrical safety. Fittings must match the conduit type and be rated for the installation environment.

6.1.1 Causes of Incorrect Fitting Use

Mismatching materials, such as using a metal fitting with PVC conduit, creates stress and weakens the connection. Using an undersized or oversized fitting can lead to loose joints or deformation under pressure.

6.1.2 Consequences of Improper Fittings

Incorrect fittings reduce mechanical strength and compromise grounding, increasing the risk of electrical faults and fire. Poorly fitted connections may loosen over time, allowing moisture and debris to enter.

6.2 Improper Threading and Misaligned Connections

Improper threading and misaligned conduit connections weaken the system, causing loose joints, poor grounding, and moisture intrusion. Proper alignment and threading are essential for secure and reliable connections.

6.2.1 Causes of Threading and Alignment Issues

Shallow or overly deep threads prevent the conduit from seating properly, causing loose or unstable connections. Cross-threading occurs when the conduit isn’t aligned with the fitting, damaging the threads and weakening the joint.

6.2.2 Consequences of Poor Threading and Alignment

Loose connections can disrupt electrical continuity and allow moisture to enter the conduit, leading to corrosion and short circuits. Misaligned joints create mechanical stress, increasing the risk of cracks and separation over time.

6.3 Failing to Seal Outdoor and Wet Location Fittings

Outdoor and wet location fittings must be properly sealed to prevent moisture from entering the conduit. Water infiltration can cause corrosion, electrical shorts, and insulation failure.

6.3.1 Causes of Improper Sealing

Using standard indoor fittings in outdoor or wet locations is a common mistake. Skipping sealants or failing to seat gaskets properly can leave small gaps where moisture can enter.

6.3.2 Consequences of Poor Sealing

Moisture in the conduit can corrode metal components, weaken insulation, and cause short circuits. Trapped moisture may freeze in cold weather, expanding and cracking the conduit or fittings.

6.4 Over-Tightening or Under-Tightening Fittings

Improper tightening of conduit fittings can weaken connections, compromise grounding, and allow moisture to enter the system. Correct torque ensures a secure and reliable connection.

6.4.1 Causes of Improper Tightening

Over-tightening can strip threads, deform fittings, and damage conduit walls. Under-tightening creates loose connections that increase the risk of separation, poor grounding, and water ingress.

6.4.2 Consequences of Incorrect Tightening

Over-tightened PVC conduit may crack or weaken over time. Loose fittings can allow wires to shift, increasing mechanical stress and the chance of electrical faults.

7. Conclusion

Avoiding common conduit installation mistakes helps ensure a safe, reliable, and code-compliant electrical system. Choosing the right conduit material, using proper bending techniques, maintaining correct fill limits, and securing joints and fittings correctly are essential for long-term performance.

Understanding the causes and consequences of these mistakes allows DIYers to approach conduit installation with greater confidence and precision. When in doubt, consulting a licensed electrician can prevent costly errors and improve safety. Taking the time to install conduits correctly not only protects the wiring but also enhances the overall efficiency and longevity of the electrical system.

Thank you for reading! Hope this post helpful. Ctube specialize in high-quality electrical conduits and fittings designed to meet industry standards and provide long-lasting performance. Whether you’re working on a residential, commercial, or industrial project, Ctube products are built to withstand tough environmental conditions while ensuring easy installation and reliable protection. For more information, visit our website or contact us.

FAQs

1. How deep should I bury electrical conduit?

The burial depth for electrical conduit depends on several factors, including the material of the conduit, the type of installation, and the burial environment. Proper burial depth ensures that the conduit is protected from physical damage, moisture, and environmental stress.

2. How long should I let PVC solvent cement cure before running wires?

For most PVC cement, allow at least 15 minutes of curing time for small conduit sizes and up to 24 hours for large conduits or cold weather conditions. Check the manufacturer’s instructions for specific recommendations.

3. How do I know if a conduit is rated for outdoor use?

Check the conduit markings. Outdoor-rated PVC conduit will be labeled with terms like “sunlight resistant” or “UV rated.” Metal conduits for outdoor use, like RMC and IMC, are usually galvanized or coated to prevent corrosion.