Table of Contents

Toggle1, Introduction

If you are familiar with PVC pipes, you probably understand why they are used in many applications worldwide. PVC is widely used for manufacturing water mains, irrigation and sewage pipes, non-food packing, canvas, and inflatable products. PVC is a rigid, flexible, and strong thermoplastic and comes with other unique combinations of properties.

Those who are not well-acquainted with PVC electrical conduit will wonder whether there are clear PVC conduits available. Clear PVC also comes in electrical conduit form, though the fittings and conduits are more rigid to find than the standard gray and white PVC. Significantly, clear PVC electrical conduit is more special compared to standard PVC conduit of the same size and make.

When undertaking an electrical project, you should be considerate about the kind of conduits you choose. Clear PVC electrical conduit is all about using conduits that can allow visual monitoring of wiring or their integrity. This interesting material is essential when visual inspection is required in clean room applications to maintain the conduits or systems’ integrity.

2, What is Clear PVC Electrical Conduit?

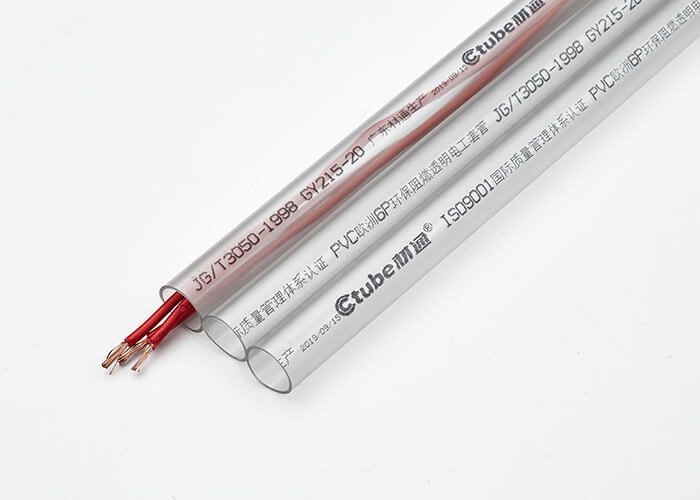

what is clear PVC electrical conduit? Transparent electrical conduit, so called clear PVC conduit, offers a versatile solution for electrical wiring applications. With its transparent properties, it allows for visual inspection of the wiring inside, while also providing various colors and sizes to suit different needs.

It may also be available in different sizes, indicating varying wall thicknesses to meet specific durability and strength needs. While primarily transparent, wire tubing may come in various colors and tints, including purple, blue, white, and grey, adding aesthetic variety while maintaining transparency.

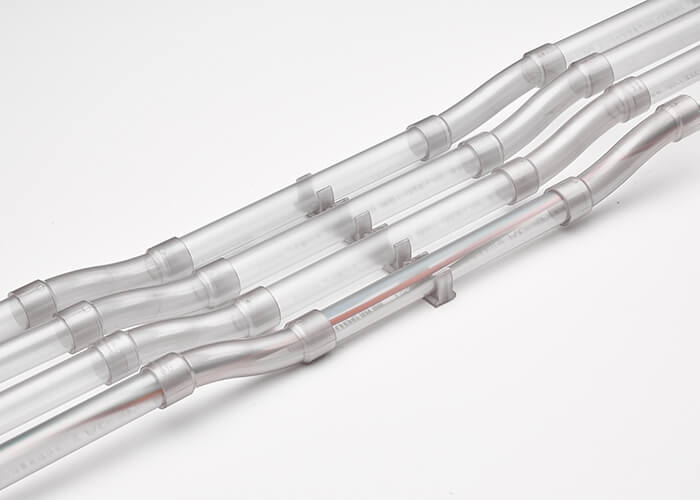

Complementing transparent wire tubing are a variety of fittings and accessories designed for installation and connection purposes, like coupling, elbow, sweep bend, screw adapter, straight tee and etc..

Clear PVC electrical conduit must be carefully manufactured, monitored, and packaged to maintain its highest clarity as possible. Some of the high-end types of clear polyvinyl chloride conduits or systems are manufactured to rigorous standards and are excellent for specific applications.

3, The Applications of Clear PVC Conduits in Industries

Many fields choose to use transparent tubing due to its unique characteristics. Transparent pipe is widely used because it allows fluid transfer with visual monitoring. Its excellent clarity makes it ideal for tubing containment, visual flow and leak detection, and sight glasses, providing a versatile, cost-effective alternative for many piping applications where visual monitoring of processes is critical.

Other fields that utilize clear PVC pipes and fittings include sight glass, waste treatment, dual containment piping, plating, and microchip fabrication, all of which benefit from the ability to visually monitor processes. The electrical field, in particular, chooses clear PVC conduit for its advantages in allowing visual inspection of wiring integrity, facilitating early detection of issues and ensuring high-quality craftsmanship in construction.

What is PVC clear electrical conduit used for?

PVC clear electrical conduit is primarily used in electrical installations where visual monitoring of wiring integrity is essential. Its transparent nature allows electricians and inspectors to easily observe the condition of the wires inside the conduit, enabling early detection of any damage, knots, or other issues that may arise during installation or over time. This transparency also facilitates troubleshooting and maintenance tasks, making it easier to identify and address electrical problems. Additionally, PVC clear electrical conduit is commonly used in clean room applications and areas where aesthetics are important, as its sleek appearance enhances the overall look of the installation.

PVC clear electrical conduit is used in a variety of specific electrical applications where the ability to visually inspect wiring is crucial. Here are some detailed examples:

Commercial Building Electrical Systems

In commercial buildings, clear PVC conduit plays a critical role in housing and protecting electrical wiring for various systems, including lighting, power distribution, and other essential electrical infrastructures. The transparency of the conduit offers a significant advantage by allowing electricians and maintenance personnel to visually inspect the wiring without dismantling the conduit itself. This visibility ensures that any potential issues, such as insulation damage, wear and tear, or loose connections, can be promptly identified and addressed. This proactive approach not only enhances the safety and reliability of the electrical systems but also minimizes downtime and maintenance costs, ensuring that the building’s operations run smoothly and efficiently.

Data Centers and Server Rooms

Data centers and server rooms are hubs of complex cabling and wiring configurations, necessary to support the vast array of servers, networking equipment, and data storage solutions. In these environments, clear PVC conduit is indispensable. Its transparency allows IT professionals to easily identify, trace, and manage specific cables during routine maintenance or troubleshooting sessions. This capability is crucial for maintaining the operational integrity of the data center, as it reduces the risk of errors and minimizes downtime during cable management tasks. By ensuring that cables are correctly routed and intact, clear PVC conduit helps maintain optimal performance and reliability of the critical infrastructure in data centers.

Industrial Automation

Manufacturing facilities increasingly rely on sophisticated automation systems, including industrial robots, conveyor systems, and various automated machinery. In these settings, clear PVC conduit is used to protect and organize the intricate wiring that powers and controls this equipment. The transparency of the conduit allows maintenance technicians to perform visual inspections, ensuring that the wiring is in good condition and connections are secure. This capability is vital for preventing unexpected equipment failures, which can lead to costly production downtime and safety hazards. By facilitating regular and thorough inspections, clear PVC conduit helps maintain the efficiency and safety of industrial automation systems.

Control Panels

Control panels in industrial and commercial environments often contain a multitude of wires connecting various devices and components. Clear PVC conduit is utilized in these control panels to organize and protect the wiring. The transparency of the conduit offers a distinct advantage by allowing technicians to quickly inspect and verify the integrity of the wiring. This visual access ensures that all connections are correctly installed and functioning as intended, making it easier to identify and rectify any wiring issues. Consequently, clear PVC conduit contributes to the reliability and effectiveness of control panels, ensuring that the systems they manage operate without interruption.

Hazardous Environments

In environments where electrical systems are exposed to hazardous conditions, such as the presence of gases, dust, or other potentially dangerous materials, clear PVC conduit provides an added layer of safety and monitoring capability. Inspectors can visually check the condition of the wiring housed within the conduit without directly exposing it to the hazardous environment. This transparency allows for regular, non-intrusive inspections, helping to ensure that the wiring remains intact and safe to operate. By facilitating such inspections, clear PVC conduit helps mitigate the risk of electrical faults and enhances the overall safety of operations in hazardous environments.

Medical and Laboratory Equipment

Medical facilities and laboratories house sensitive and critical equipment that relies on stable and reliable electrical connections. Clear PVC conduit is used to protect the wiring for such equipment, ensuring that it is shielded from potential damage and wear. The ability to see through the conduit allows maintenance personnel to perform regular inspections, confirming that the wiring is free from damage and properly maintained. This proactive approach is essential for the reliable operation of medical devices and laboratory instruments, where even minor electrical issues can lead to significant disruptions or compromises in patient care and research accuracy.

Residential Smart Home Installations

In residential settings, the integration of smart home technology has become increasingly prevalent, encompassing home automation, security systems, and entertainment setups. Clear PVC conduit is used to manage the wiring for these smart systems, providing a clean and organized solution that simplifies installation and maintenance. Homeowners and technicians benefit from the transparency of the conduit, as it allows for easy inspection and verification of the wiring. This capability ensures that all smart home devices are correctly connected and functioning as intended, providing a seamless and reliable user experience. By facilitating proper wiring management, clear PVC conduit enhances the efficiency and reliability of smart home installations.

By using clear PVC electrical conduit in these applications, professionals can ensure that their electrical systems are safe, reliable, and easy to maintain, with the added benefit of being able to visually inspect the wiring at any time.

4, Benefits of Utilizing Transparent Electrical Conduits Solutions

Utilizing transparent electrical conduit solutions offers numerous benefits across various applications, particularly in settings where visual monitoring and maintenance of electrical wiring are critical. Here are some key advantages:

Enhanced Safety and Maintenance

– Visual Inspection: One of the most prominent benefits of transparent conduits is the ability to conduct immediate visual inspections. Electricians and maintenance personnel can quickly identify potential issues such as insulation damage, overheating, moisture ingress, or improper connections without the need to dismantle the conduit. This feature greatly enhances the safety of electrical systems by allowing for real-time monitoring and assessment.

– Early Problem Detection: The transparency of these conduits facilitates early detection of potential problems. By regularly inspecting the wiring, maintenance teams can spot signs of wear and tear, loose connections, or other issues that could lead to electrical fires or system failures. Early intervention helps mitigate risks and ensures the continued safe operation of electrical systems.

Improved Aesthetics and Organization

– Neat Appearance: Transparent conduits contribute to a clean and organized appearance, which is particularly important in settings where aesthetics are a priority, such as commercial buildings, smart homes, and public display installations. The ability to see through the conduit ensures that the wiring is orderly and not cluttered, enhancing the overall visual appeal of the installation.

– Cable Management: Effective cable management is crucial in complex wiring systems. Transparent conduits make it easier to manage and organize cables, allowing technicians to trace and follow wiring paths with ease. This organization simplifies maintenance tasks and reduces the likelihood of wiring errors during installation and repairs.

Ease of Installation and Troubleshooting

– Simplified Troubleshooting: Transparent conduits significantly streamline the troubleshooting process. When electrical issues arise, technicians can quickly trace the wiring within the conduit to identify faults or areas of concern. This visibility reduces the time and effort required for diagnostics and repairs, ensuring that systems are back up and running swiftly.

– Efficient Installation: During the installation phase, clear conduits enable installers to verify that wires are correctly routed, untangled, and free from damage. This transparency ensures that the initial setup is done correctly, reducing the chances of errors that could lead to future maintenance issues.

Durability and Performance

– Material Strength: Transparent PVC conduits are engineered for durability, offering resistance to corrosion, impact, and extreme temperatures. This robust construction ensures that the conduits maintain their integrity and performance over long periods, even in challenging environments.

– Compliance with Standards: Many transparent PVC conduits are manufactured to adhere to industry standards and safety regulations. This compliance guarantees that the conduits are suitable for a wide range of applications, providing assurance of their quality and reliability.

Cost-Effectiveness

– Reduced Downtime: The ability to perform quick and accurate inspections with transparent conduits minimizes downtime associated with maintenance and repairs. By identifying and addressing issues promptly, these conduits help maintain continuous operation of electrical systems, which is particularly valuable in commercial and industrial settings.

– Lower Maintenance Costs: Transparent conduits simplify the monitoring and maintenance of wiring systems, which can lead to significant cost savings over time. The reduced need for invasive inspections and the ability to quickly address potential problems lower the overall maintenance expenses, making these conduits a cost-effective choice for long-term use.

5, Differences Between Clear Conduit and Other Types

Comparison Criteria:

1. Material

2. Performance

3. Advantages

4. Disadvantages

5. Application Scenarios

Clear PVC Conduit

Material: Transparent Polyvinyl Chloride (PVC)

Performance:

– Transparency: Allows visual inspection of wiring.

– Durability: Good resistance to impact, chemicals, and corrosion.

– Flexibility: Moderate flexibility, primarily used in rigid form.

– Temperature Resistance: Limited resistance to high temperatures.

Advantages:

– Visual Monitoring: Enables continuous visual inspection of wiring.

– Aesthetics: Provides a clean, organized appearance.

– Corrosion Resistance: Excellent for damp or corrosive environments.

– Lightweight: Easy to handle and install.

Disadvantages:

– UV Sensitivity: Can degrade with prolonged UV exposure.

– Cost: More expensive than standard PVC.

– Heat Resistance: Not suitable for high-temperature environments.

Standard PVC Conduit (Non-Clear)

Material: Opaque Polyvinyl Chloride (PVC)

Performance:

– Durability: Good resistance to impact, chemicals, and corrosion.

– Flexibility: Moderate flexibility.

– Temperature Resistance: Limited resistance to high temperatures.

Advantages:

– Cost-Effective: Generally cheaper than clear PVC and metal conduits.

– Corrosion Resistance: Excellent for damp or corrosive environments.

– Lightweight: Easy to handle and install.

– Non-Conductive: Eliminates grounding concerns.

Disadvantages:

– Heat Resistance: Not suitable for high-temperature applications.

– Strength: Less impact-resistant compared to metal conduits.

Application Scenarios:

– Residential Wiring: Commonly used in homes for general electrical wiring.

– Commercial Buildings: Used in commercial settings requiring corrosion resistance.

– Underground Installations: Ideal for underground wiring due to its corrosion resistance.

Metal Conduit (EMT, RMC, IMC)

Material: Steel or Aluminum

Performance:

– Strength: Highly durable and resistant to physical damage.

– Grounding: Provides excellent electrical grounding.

– Temperature Resistance: Can withstand high temperatures.

Advantages:

– Durability: Very strong and impact-resistant.

– Fire Resistance: Can withstand higher temperatures without degrading.

– Grounding: Can serve as a grounding conductor.

Disadvantages:

– Weight: Heavier and more difficult to install.

– Cost: More expensive than PVC conduits.

– Corrosion: Steel conduits can corrode if not properly protected, though aluminum resists corrosion better.

Application Scenarios:

– Industrial Environments: Suitable for factories and plants where mechanical protection is paramount.

– High-Traffic Areas: Ideal for locations with a high risk of physical damage.

– Fire-Prone Areas: Used in settings where fire resistance is essential, such as in buildings requiring high safety standards.

FMC and LFMC

Material:

Flexible Metal Conduit (FMC):Interlocking metal strips

Liquidtight Flexible Metal Conduit (LFMC): Metal with a waterproof coating

Performance:

– Flexibility: Can be bent and routed around obstacles.

– Protection: LFMC provides moisture resistance.

Advantages:

– Flexibility: Ideal for complex installations with many bends.

– Protection: LFMC offers excellent protection against moisture and chemicals.

Disadvantages:

– Durability: Less resistant to impact compared to rigid metal conduits.

– Cost: More expensive than rigid conduits.

– Installation: More time-consuming to install due to its flexibility.

Application Scenarios:

– Complex Installations: Perfect for applications requiring a lot of bends and flexibility.

– Outdoor and Wet Locations: LFMC is used in environments exposed to water and moisture.

– Machinery and Equipment: Ideal for connecting movable machinery that requires flexible connections.

Rigid Nonmetallic Conduit (RNC)

Material: Nonmetallic materials such as PVC or HDPE

Performance:

– Durability: Resistant to chemicals, corrosion, and impact.

– Flexibility: HDPE is more flexible compared to rigid PVC.

– Temperature Resistance: Limited resistance to high temperatures.

Advantages:

– Corrosion Resistance: Excellent for use in corrosive environments.

– Lightweight: Easy to handle and install.

– Cost-Effective: Generally cheaper than metal conduits.

Disadvantages:

– Impact Resistance: Lower compared to metal conduits.

– UV Degradation: Can degrade under prolonged sunlight exposure if not UV-protected.

– Heat Resistance: Not suitable for high-temperature environments.

Application Scenarios:

– Corrosive Environments: Used in chemical plants or near seawater where corrosion is a major concern.

– Underground and Direct Burial: Suitable for wiring that needs to be buried underground.

– Residential and Commercial Applications: Employed where non-metallic properties are beneficial.

Choosing the right conduit type depends on the specific needs of the application, including environmental conditions, the need for visual monitoring, mechanical protection, and budget constraints.

6, Conclusion

In conclusion, clear PVC electrical conduit offers numerous advantages for a variety of applications, particularly where visual monitoring and high safety standards are critical. Its transparency allows for easy inspection of wiring integrity, which is crucial in clean rooms, medical facilities, data centers, and aesthetically sensitive installations.

Ctube’s transparent and clear pvc electrical conduits stand out due to their exceptional environmental quality, flame retardancy, durability, and safety features. Made from premium, environmentally friendly materials meeting European 6P standards, they avoid recycled content and follow IEC 62321-8:2017 testing standards. These conduits meet the European V-0 flame retardant standard, extinguishing fires quickly without spreading or producing harmful debris.

Constructed from pure PVC, they withstand harsh conditions, including impacts and extreme temperatures as low as -15°C, and can handle high voltage without penetration, ensuring insulation and durability. Their transparency offers significant safety benefits, allowing for easy inspection, ensuring proper wiring installation, and quickly identifying and correcting issues like wire damage or entanglement.

Selecting the appropriate conduit for a project requires a professional evaluation tailored to the specific needs of the installation. It’s crucial to assess various factors to determine which conduit best aligns with the project requirements. By carefully considering aspects such as environmental conditions, mechanical protection, visual monitoring needs, and budget constraints, the most suitable conduit can be chosen to ensure optimal performance and safety.