Table of Contents

Toggle1. Introduction

Black PVC corrugated conduit is a flexible and durable solution for protecting electrical and data cables in various environments. Its corrugated design allows for enhanced flexibility, making it ideal for installations in tight spaces and areas requiring frequent bends. The use of black color not only improves the conduit’s resistance to UV rays and heat but also gives it a professional appearance, making it suitable for both indoor and outdoor applications.

This type of conduit is widely used in residential, commercial, industrial, and automotive settings due to its lightweight nature, ease of installation, and excellent resistance to environmental factors such as moisture, chemicals, and mechanical stress. We’ll explore the details of black PVC corrugated conduit.

2. Types of Black PVC Corrugated Conduit

Black PVC corrugated conduit is a widely used solution for protecting electrical and communication cables. Its lightweight structure, flexibility, and resistance to environmental and mechanical stress make it an essential component in both residential and industrial settings. Understanding the differences between regular and open-design black PVC conduit helps in selecting the best option for specific applications.

2.1 Regular Black PVC Corrugated Conduit

2.1.1 Definition and Structure

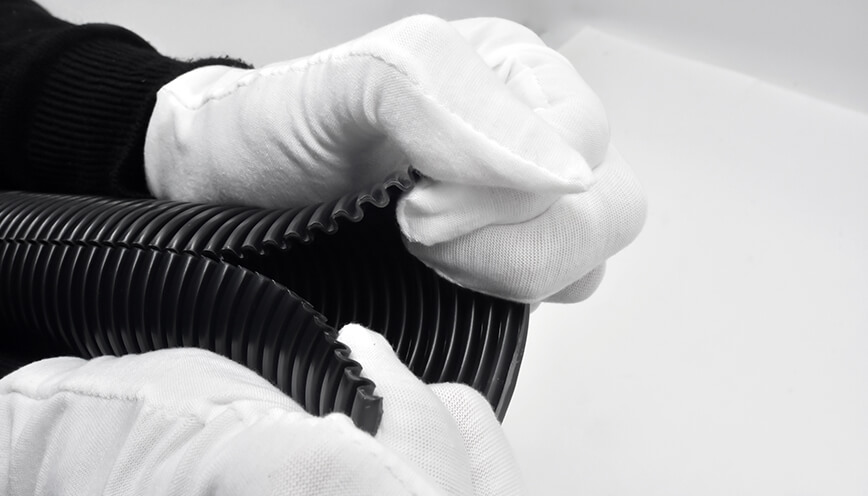

Regular black PVC corrugated conduit is made from polyvinyl chloride (PVC), a thermoplastic material known for its high durability, flexibility, and chemical resistance. The conduit features a corrugated exterior with alternating ridges and grooves along its entire length, which enhances its flexibility while maintaining structural strength.

The manufacturing process involves extruding PVC material through a corrugation mold, which forms the distinctive ridged pattern. This design improves the conduit’s ability to bend without collapsing or breaking under pressure. The continuous, unbroken structure ensures that the internal wiring remains fully enclosed, offering consistent protection against mechanical damage, moisture, and environmental factors.

2.1.2 Key Features and Benefits

High Flexibility: The corrugated shape allows the conduit to bend easily, making it suitable for installations in complex or confined spaces. It can flex around obstacles without needing extra fittings or connectors, which reduces material and labor costs.

Strength and Durability: Despite its lightweight structure, regular black PVC corrugated conduit is highly resistant to impact, crushing, and mechanical stress. It protects the wiring inside from physical damage and ensures long-lasting performance.

UV and Weather Resistance: The black color enhances the conduit’s resistance to ultraviolet (UV) rays. This prevents the material from becoming brittle or cracked when exposed to sunlight, making it suitable for both indoor and outdoor use.

Moisture and Chemical Resistance: PVC is naturally resistant to moisture and chemicals, making this conduit ideal for use in wet or corrosive environments, such as underground or industrial installations.

Lightweight and Easy to Install: The lightweight nature of PVC makes the conduit easy to transport and handle during installation. Its flexibility allows for quicker installation, reducing labor time and costs.

2.1.3 Common Applications

Electrical Wiring Protection: Used to protect electrical cables in residential and commercial buildings, including walls, ceilings, and floors.

Automotive Wiring: Commonly used to protect vehicle wiring systems from vibration, heat, and exposure to chemicals.

Underground Installations: Suitable for use in underground electrical and communication systems due to its resistance to moisture and soil pressure.

Industrial Machinery: Protects control cables and wiring in manufacturing and processing facilities.

2.2 Black PVC Split Corrugated Conduit

2.2.1 What is Black PVC Corrugated Split Conduit?

Black PVC split corrugated conduit is designed with pre-cut slits or perforations along its length. These conduits allow you to insert, remove, or adjust cables without having to disconnect the entire conduit or cut into the material. The openings are positioned at regular intervals, ensuring easy access while maintaining the conduit’s structural integrity.

2.2.2 How Split Conduit Improve Flexibility and Accessibility?

Easy Cable Insertion and Removal: The slits make it easy to insert and remove cables without needing to cut the conduit or disassemble the entire wiring system. This is especially useful when upgrading or repairing wiring.

Enhanced Maintenance and Troubleshooting: The openings allow you to access the wiring quickly for inspection or troubleshooting without damaging the conduit. This reduces downtime and repair costs.

Retains Structural Strength: Despite having openings, the conduit remains strong and resistant to mechanical stress, ensuring that the internal wiring remains protected from physical damage.

Better Airflow and Heat Dissipation: The openings can also help with heat dissipation, reducing the risk of overheating in high-power or high-frequency cable systems.

2.2.3 Suitable Applications

Telecommunications and Data Cable Management: Often used to organize and protect fiber optic and network cables in office buildings, data centers, and communication networks.

Automotive Wiring: Ideal for protecting vehicle wiring while allowing quick access for adjustments and repairs.

Industrial Control Systems: Used in manufacturing facilities to manage wiring for machinery and equipment that require frequent maintenance.

Home and Commercial Renovations: The openings simplify cable adjustments during construction or remodeling projects.

2.3 Comparing Regular and Open-Design Conduit

| Feature | Regular Black PVC Corrugated Conduit | Black PVC Split Corrugated Conduit |

| Flexibility | High | High |

| Structural Strength | Stronger due to continuous design | Slightly reduced due to openings |

| Ease of Installation | Simple, but requires cutting for cable adjustments | Easier due to cable access through openings |

| Maintenance and Repairs | Requires cutting or disassembly | Quick access for adjustments and repairs |

| Heat Dissipation | Limited | Improved due to ventilation through openings |

| Best for | Long-term, fixed installations | Systems requiring frequent access and modifications |

| Common Uses | Residential, industrial, and automotive | Data centers, commercial buildings, and machinery |

Regular black PVC corrugated conduit offers greater strength and protection, making it suitable for permanent installations. In contrast, split corrugated conduit provides enhanced flexibility and ease of maintenance, making it ideal for applications requiring frequent cable adjustments.

3. Why Black Color Matters for PVC Corrugated Conduit

The color of PVC conduit plays a significant role in its performance, longevity, and suitability for specific applications. Black PVC corrugated conduit is chosen not only for aesthetic reasons but also for its functional advantages, including enhanced UV resistance, heat absorption properties, and improved visibility or blending in different environments.

This section explores the reasons behind using black PVC and how it benefits various applications.

3.1 Enhanced UV Resistance

Black PVC contains carbon black, a material that acts as a UV stabilizer.

Carbon black absorbs UV rays and converts them into heat, which is dissipated through the conduit’s surface without degrading the PVC structure.

The black pigmentation prevents the breakdown of polymer chains, which can lead to cracking, brittleness, and discoloration over time.

3.1.2 Long-Term Durability in Outdoor Conditions

UV exposure can cause non-black PVC conduit to become brittle and prone to cracking.

Black conduit retains its flexibility and mechanical strength even under prolonged sun exposure.

3.2 Improved Heat Management

Black PVC conduit absorbs more heat than lighter-colored conduit due to its darker surface. While this may seem like a disadvantage, it can actually improve performance in certain applications:

3.2.1 Heat Dissipation and Thermal Expansion

The black color allows the conduit to absorb and evenly distribute heat along its length, reducing thermal stress on localized areas.

Thermal expansion of PVC is predictable and manageable, reducing the risk of warping or deformation.

Proper spacing during installation ensures that the conduit can expand and contract without damaging internal cables.

3.2.2 Prevention of Moisture Condensation

The heat retention properties of black PVC conduit reduce the formation of condensation inside the conduit.

This minimizes the risk of electrical shorts or corrosion caused by trapped moisture.

3.3 Resistance to Environmental Factors

Black PVC conduit is engineered to withstand a variety of environmental stressors, including temperature extremes, moisture, and chemical exposure:

3.3.1 Performance in Extreme Temperatures

Black PVC conduit maintains its flexibility and strength at both high and low temperatures.

It resists cracking or softening, ensuring that internal cables remain protected under harsh weather conditions.

3.3.2 Chemical and Corrosion Resistance

The black color does not affect the inherent chemical resistance of PVC.

It withstands exposure to acids, alkalis, oils, and solvents without degrading.

3.4 Aesthetic and Practical Considerations

Black PVC conduit is often preferred for its visual appeal and ability to blend or contrast with various environments:

3.4.1 Improved Concealment in Dark Environments

Black conduit blends well with dark surfaces, ceilings, and walls, making it less visually obtrusive.

In industrial settings, it helps maintain a clean and uniform appearance.

3.5 Standardization and Industry Preferences

Black PVC conduit has become a preferred choice in various industries due to its consistent performance and adherence to safety and performance standards:

3.5.1 Compliance with Industry Standards

Black PVC conduit meets various industry-specific requirements for UV resistance, thermal stability, and chemical resistance.

Regulatory bodies such as the National Electrical Code (NEC) and ASTM recognize black PVC as a suitable material for outdoor and underground installations.

3.5.2 Widespread Industry Use

Black PVC conduit is used in sectors ranging from residential construction to industrial automation and solar power.

Its versatility and reliability have made it a standard choice among contractors and engineers.

4. Step-by-Step Guide for Installing Black PVC Corrugated Conduit

Proper installation of black PVC corrugated conduit is essential for ensuring the durability and safety of electrical systems. This step-by-step guide covers the complete process, from preparation to final testing, helping to achieve a secure and code-compliant installation.

4.1 Tools and Materials Required for a Successful Installation

4.1.1 Essential Tools

PVC Cutter or Fine-Toothed Saw – For cutting the conduit to the desired length.

Measuring Tape – To measure the conduit path accurately.

Deburring Tool or File – To smooth rough edges after cutting.

Fish Tape or Pull String – For guiding electrical wires through the conduit.

Conduit Bender – If needed for forming smooth bends in the conduit.

Drill and Drill Bits – For creating mounting holes in walls, ceilings, or other surfaces.

Screwdriver or Wrench – For securing clamps and fasteners.

4.1.2 Required Materials

Black PVC Corrugated Conduit – Ensure the conduit meets the required size and specifications for the project.

Connectors and Couplings – For joining conduit sections and creating secure connections.

Conduit Clamps or Straps – For securing the conduit along walls, ceilings, or underground.

Cable Lubricant – To reduce friction when pulling wires through the conduit.

Electrical Tape – For sealing and securing wire ends.

Weatherproof Sealant (if needed) – For protecting connections from moisture and environmental damage.

4.2 Preparation Before Installation

Thorough preparation helps prevent errors and improves installation efficiency.

4.2.1 Inspect the Installation Area

Evaluate the Environment: Confirm the conduit path is free of obstructions like pipes, structural elements, or existing wiring. Ensure the surface is clean and dry to promote strong adhesion and secure mounting.

Check Code and Compliance Requirements: Review the National Electrical Code (NEC) and local regulations for conduit size, fill capacity, and grounding. Ensure the conduit and fittings meet the specified temperature and environmental ratings.

4.2.2 Measure and Mark the Path

Measure Conduit Length: Use a measuring tape to determine the total length of conduit required. Account for bends and offsets when calculating conduit length.

Mark Conduit Path: Use chalk or a marker to outline the conduit path on the installation surface. Avoid sharp corners or sudden changes in direction to maintain smooth wire flow.

4.2.3 Cut and Prepare the Conduit

Cut the Conduit: Use a PVC cutter or fine-toothed saw for a clean, straight cut. Avoid crushing the corrugated walls while cutting.

Deburr the Edges: Remove any rough edges using a deburring tool or file. Smooth edges prevent wire insulation damage and ensure a secure fit in connectors.

4.3 Step-by-Step Installation Process

Following a systematic approach ensures that the conduit is properly installed and securely mounted.

4.3.1 Installing Straight Runs

Lay Out the Conduit: Position the conduit along the marked path. Ensure that the conduit aligns with the planned route.

Secure the Conduit: Use conduit clamps or straps to hold the conduit in place. Place clamps at regular intervals (typically every 3–4 feet) to prevent sagging or movement.

Join Conduit Sections: Use connectors or couplings to join conduit sections. Apply solvent cement or adhesive (if required) to create a secure connection. Ensure that the conduit ends are flush with the fitting interior.

4.3.2 Making Bends and Turns

Use Factory-Made Elbows or Bend the Conduit: If the conduit requires bending, use a conduit bender to create smooth, gradual curves. Avoid tight bends that could restrict wire movement or damage the conduit.

Maintain Minimum Bend Radius: Follow the manufacturer’s guidelines for the minimum allowable bend radius. Bends that are too sharp may weaken the conduit and increase pulling resistance.

Secure Bends with Clamps: Add clamps at the start and end of each bend to prevent movement.

4.3.3 Installing Underground Conduit

Excavate the Trench: Dig a trench to the required depth according to local building codes. Ensure the trench is level and free of sharp objects or debris.

Lay the Conduit: Position the conduit in the trench, ensuring a consistent depth. Leave some slack to account for thermal expansion and contraction.

Backfill the Trench: Cover the conduit with a layer of fine sand or soil. Compact the backfill carefully to avoid damaging the conduit.

4.3.4 Installing Through Walls or Floors

Drill an Access Hole: Use a hole saw or drill to create an opening large enough for the conduit. Smooth the hole edges to prevent conduit damage.

Insert and Seal the Conduit: Pass the conduit through the opening. Use caulk or expanding foam to seal the opening and prevent moisture infiltration.

Secure the Conduit: Use clamps or fasteners to hold the conduit in place. Ensure that the conduit remains aligned and free of kinks.

4.3.5 Running Conduit Along Ceilings or Walls

Position the Conduit: Lay out the conduit along the planned path. Allow space for natural expansion and contraction.

Secure with Clamps: Place clamps at regular intervals (typically every 3–4 feet). Ensure that the conduit remains straight and aligned.

4.4 Pulling Wires Through the Conduit

Careful wire pulling minimizes stress on both the conduit and the electrical wires.

4.4.1 Preparing to Pull Wires

Choose Correct Wire Size: Confirm that the wire size matches the conduit capacity. Avoid overfilling, as it can increase heat and reduce flexibility.

Lubricate the Wires: Apply a thin layer of cable lubricant to reduce friction. Use a manufacturer-recommended lubricant suitable for PVC.

4.4.2 Pulling the Wires

Insert Fish Tape: Feed the fish tape through the conduit until it reaches the other end. Attach the wires to the fish tape using electrical tape.

Pull Slowly and Evenly:Pull the wires steadily to avoid kinking or tangling. If resistance increases, stop and apply more lubricant.

Test for Continuity: After pulling, test the wires for continuity and grounding.

4.5 Sealing and Securing Connections

Proper sealing ensures that the conduit system remains moisture-resistant and secure.

Seal Joints and Fittings: Use solvent cement or adhesive to secure connections. Ensure that all connections are watertight and secure.

Protect Exposed Conduit: For outdoor installations, apply UV-resistant coating or shielding.

Use conduit covers or guards in high-traffic areas.

Inspect and Test: Check for loose fittings or sagging conduit. Test the system for electrical continuity and insulation resistance.

5. Conclusion: Choosing the Right Black PVC Corrugated Conduit for Your Project

Choosing the right black PVC corrugated conduit is essential for ensuring a secure and long-lasting electrical installation. Its flexibility, strength, and resistance to environmental factors make it suitable for a wide range of applications, from residential to industrial settings. The UV-resistant properties and ability to withstand moisture and chemicals further enhance its reliability in both indoor and outdoor environments.

When selecting a black PVC corrugated conduit, it’s important to consider the specific installation requirements, including environmental conditions, electrical load, and compatibility with existing systems. Ensuring compliance with industry standards, such as ASTM and NEC regulations, will guarantee safety and performance. By carefully evaluating these factors, you can achieve a durable and efficient conduit system tailored to your project’s needs.

Ctube offers high-quality black PVC corrugated conduit designed to meet the demands of various electrical installations. Engineered for durability and flexibility, Ctube’s conduit is resistant to UV exposure, moisture, and chemicals, ensuring reliable protection for electrical wiring in challenging conditions. In addition to black PVC corrugated conduit, Ctube also provides UPVC solar conduit for enhanced UV resistance in solar applications and LSZH (Low Smoke Zero Halogen) conduit for improved fire safety and reduced toxic emissions, making it ideal for sensitive environments.

FAQs

1. How does black PVC corrugated conduit compare to metal conduit?

Black PVC corrugated conduit is lighter, more flexible, and resistant to corrosion and chemicals compared to metal conduit. While metal conduit provides better physical protection, PVC corrugated conduit is easier to install and more cost-effective for most applications.

2. Can black PVC corrugated conduit handle high temperatures?

Yes, black PVC corrugated conduit can withstand a range of temperatures, but extreme heat may affect its structural integrity over time. Always check the manufacturer’s temperature ratings before installation.

For example, Ctube’s black PVC corrugated conduit withstands temperatures from -15°C to 105°C for regular PVC and UPVC, and from -45°C to 150°C for low-smoke halogen-free conduit, ensuring reliable performance in extreme conditions.

3. What types of wiring are compatible with black PVC corrugated conduit?

Black PVC corrugated conduit is compatible with most types of electrical wiring, including low-voltage, communication, and data cables. Ensure that the conduit size matches the wire gauge and follow local electrical codes.