Table of Contents

TogglePart 1,What is Electrical Conduit?

Before we talked about how to make electrical conduit,you should be knows what is electrical conduit.You can simply click here learn more on Wikipedia.In a word,electrical conduit is kind of pipe installed in your house for protect the electrical wire.

Different type of pipes has different performance in general.Such as the metal or Non-metal,you must be know metal is harder than plastic.But we only talked about non-metal one for this is our area.

We also seen most of DIYer applied the PVC conduit for chairs or watering your plants,that’s great.But may be you do not know how bad product works for you or your plants.For example,some of product on the market has used defective raw materials and then contact your skin,it’s nightmare!

This kind of materials separate out hydrogen chloride after exposed in sunlight and it is totally harm for your health. What’s more serious is that TCDD has been produced during the recycling and processing of such products, which can lead to poisoning in some cases.

Part 2,How to Make an Electrical Conduit?

First of all,make a good quality electrical conduit is not easy.Not mentioned about the all the conduit produced by extrudes machines,and the most important should be formula of materails. Wrong or inappropriate formulas will greatly affect the performance of electrical pipes, and may even directly lead to batch scrapping. The formula mentioned here does not refer to the color formula, but the ratio of various additives and materials in the production process.

We’d like to list the simply production process as below,

- Raw Materials Preparing

- Mixing Additives Formula

- Loading & Feeding Materials

- Extruding & Vacuum Shape

- Cooling

- Information Printing

- Cutting

- Quality Inspection

- Packing & Shipment

It seems not easy to understand.Ok.let’s explains them one by one.

1. Raw Materials Preparing

It looks like easiest step in production,right?But there is most important things that you need make sure purchased brand new materials instead of recycled materails.Why?If you purchased latter one,you will found your product performance will be dramatic down matched with normal product on the market because most recycled materials contained a lot of impurities,and they have been processed by high temperature, so it will seriously affect the quality of the product.

In a word,you need to manage your suppliers well, and have a raw material inspection department, and check & record each batch of incoming materials to ensure the quality of raw materials.

BTY,you need a good condition warehouse for restore these materials and make sure your materials keep good condition always.

2. Mixing Additives Formula

This step is secret of the whole industry,so we can not reveal too much.But we would like to say this step is high related with your product quality.For example,when you burning the electrician tube, it can be stop the burning well? Does it emit light smoke or black smoke after burning? After the heavy rolled by other object, can it be kept good condition?

BTW,the additives has different grade on the market,right?

The safety requirements of a good electrician tube are second only to the food level and reach the level of kids toy. As we mentioned as above, using inferior materials and incorrect chemical preparations can seriously damage your health.That’s why we built a lab by ourself.

3. Loading & Feeding Materials

In this step,all the mixed materials will be loaded and entered into the feeding system. In fact, most of this step is realized and controlled by the machine. The focus is on feeding at a constant speed to ensure that the subsequent extrusion process can proceed at a normal and uniform speed and to ensure the quality of the product.

At the same time, experienced debugging workers will adjust the feeding time according to the quality of the product and the running state of the machine, which is conducive to the long-term stable operation of the machine and ensures stable product quality.

4. Extruding & Vacuum Shape

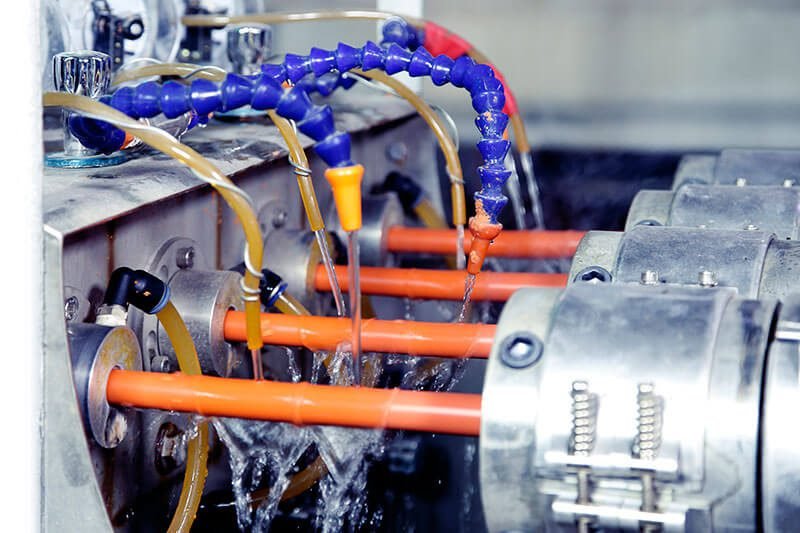

First, the plasticized materials flows through the extrusion die under the pressure of the screw, passes through the sizing sleeve to form a pipe with a firm diameter, and then is shaped by a vacuum shaping box. This step is the core part of the extrusion process, and it is also the key process of turning plastic raw materials into plastic electrical tubes.

Although it looks easy, in fact, there are too many problems should be happened during mass production.

For example, is the pressure of the screw always stable? Is the extrusion mold in good condition, whether the mold temperature is controlled reasonably?There is rest plastic glue in the mold that affects the works for the mold? Hou about the small round hole distribution or diameter of the vacuum sizing sleeve is reasonable, etc.

These problems may affect the quality of the final product, and even cause batches to be scrapped or defective products occur the product process.

5. Cooling

Different types of materials require different cooling methods, and also need to be adjusted in the cooling process in production.

For example, PVC material needs to be cooled quickly,On the contrary, for PP or PE material, slow cooling should be better. Because the latter material has different material properties than former, it is necessary to reduce the internal stress of the product.Otherwise it may cause problems such as cracking.

Moreover, for the slow cooling method, you need configured 3 different temperature sections on the equipment.That means the temperature is gradually reduced by hot water, warm water, and cold water to release the internal stress step by step.

6. Information Printing

You can easier seen most of information on the outside of tube such as brand,standard approved info etc.

There is a roller printer here for printing all of these information on the tube in production process.It make sure all of the tube has ‘name card’ and customer knows what brand and specification is.

7. Cutting

Most of them use traditional mechanical structure,the first one step is preset the length, and then use the pneumatic device to drive the blade to cut.

But there are still have 2 more problems here.The first is that the cut surface must be smooth and does not generate too much dust in cutting process; the second is that the length must be keep the same after setting (tolerance must be under control). Considering the current new technology grow so fast, it is not difficult to do this.

Even some of brand new extruders has been matched the laser cutting machines to replace the traditional mechanical structure for lower costs.

8. Quality Inspection

In general, product department has already participated in the inspection on the production line before quality control department join in.

But quality control department focus on the following inspections for finished products, appearance inspection,inner diameter inspection,wall thickness inspection,and bending inspection.

These are extra lots test content after production,such as flame retardant testing, compression performance testing, etc.That’s make sure all pipes are qualified when they are delivery to our customers.

9. Packing & Shipment

Almost there.It seems too easy,right?

Most consumers don’t know is that good products also need good packaging. If we applied improper packaging will lead to damage or scratches during transportation, which will also cause customer complaints and other problems.

For general industrial products, it is necessary to comprehensively consider the appearance, shape, performance and other conditions of the product, and design a reasonable packaging to avoid damage during transportation. And the right packaging can also improve customer satisfaction too.

Part 3 How to Choose an Electrical Conduit?

We talked about tons of information about ‘how to make a electrical conduit’,but we think you should be learn more about how to choose electrical conduit because most of reader will not run a factory to produce electrical conduit,right?Espically we mentioned about the bad electrical pipe will harm for your health as above.

We have summarized some tips and techniques as follows,

1. Find a Reliable Brand

Oh,man,this is not tips.

We know brand is not everything but a reliable brand means they have stabilize supply chain,quality control and after-sales services.If you purchased unknow brand cheap product,maybe they used low-quality raw materials and they refused or can not provide good after-sales service.

The electrical conduit is not same as mobile phone, you can not replaced them per year.And considering to mass money loss for labor cost for dismantling or drill the wall,it is not smart choice.Not mentioned the labor cost calculated by hour.

So you can pick a reliable brands from the beginning and installing them correctly is the best way to avoid money losses.

2. Test the Electrical Conduit by Yourself

There are simply ways to learn about the basic quality of the electrical conduit.

But the bending test and pedal test only used for common light-duty electrical conduit. For electrical pipes with thicker walls or heavy duty type, it is not recommended.

(1) Burning Test

Use your lighter for burning the pipe for test flame resistance performance.

Keep burning when you see flame on the electrician’s tube,then stopped.And count numbers in your mind.If the flame goes out within 30 seconds, it can be basic fireproof. The shorter time to goes out, means higher fireproof rating.

However,you need see what kind of smoke when the burning.If you see black smoke,that means not so environmentally friendly.In contrast,if you see light smoke,it means environmentally friendly.

(2) Bending Test

Bending the conduit to 90 degrees by hand or spring,then check the bending whitening area of bending spot.However,you can feeling the rebound or shaped performance. This can be test the toughness of the pipe and the quality of the raw material.

The pipe can not be cracking or shows too much white area after bending,or the quality is not good.

(3) Pedal Test

Get a sample and use the heel of the leather shoe to step on the surface of the pipe harder, step on different parts of the pipe body more, and then observe whether there are cracks in the stepped place, so that you can simply test the anti-stamping performance of the pipe. You need to know that most pipes are placed underground, and they need to bear weight. If the punching resistance is not good, it may breaks someday.

If you feel that it’s more laborious to step on your feet, it’s also a good choice to use a hammer instead.

(4) Beating Test

Pick suitable length, hit the pipe on the concrete floor for 5-6 times and then stop, and then see cracks on the surface. If not, it should be ok to use.

(5) High & Low Temperature Test

Perparing the same two sections of around 760mm diameter pipes.The one place in a refrigerator at -20°C and the other one place electronic oven at 70°C. After 2 hours later, taken them out, and then they will fall freely at 45° from a height of 4.9ft. If there is no break, it is qualified.

(6) UV Test

Please note this test method is only for solar conduit. If used PVC tubes instead, most of them will be failed for test.

Place 1 – 2 pipe where the sunshine time is the longest and without any protective.Check them whether the surface is discolored after 48-72 hours. If there is no discoloration or uneven color spots, it is a qualified product.

Tips,you can keep same one sample copy at beginning for easier checked the result.

That’s all of them.If you like this post,you can click ‘share button’ on top to let more people knows.Or you are still have questions about electrical conduit,feeling free to contact us for more information.