Table of Contents

Toggle1. Introduction

As a PVC electrical conduit manufacturer and exporter with over a decade of industry experience, we often encounter questions from clients asking whether we are a manufacturer or a trading company. Today, we will provide a detailed introduction and discussion on the differences between a manufacturer and a trading company.

In today’s globalized economy, the distinction between manufacturers and trading companies is pivotal for businesses engaged in sourcing and procurement. Understanding this difference is not merely academic; it has practical implications that can significantly influence sourcing decisions, quality control, and pricing strategies.

Manufacturers are companies that produce goods directly, often overseeing the entire production process from raw materials to final products.

In contrast, trading companies serve as intermediaries, facilitating transactions between manufacturers and customers without engaging in the actual production of goods.

This fundamental difference shapes how each type of company operates and serves its clients, including sourcing decisions, quality control and pricing strategies and more.

This article aims to provide a comprehensive guide on how to distinguish between manufacturers and trading companies.

2. What is a Manufacturer?

2.1 Understanding Manufacturer

A manufacturer is a business entity that engages in the transformation of raw materials into finished goods through various production processes. This transformation involves a series of activities, including design, engineering, assembly, and quality control. Manufacturers serve as vital links in the supply chain, converting resources into products that meet the needs and demands of consumers and businesses alike. They play a pivotal role in various sectors, including automotive, electronics, textiles, and consumer goods, driving innovation and economic growth.

2.2 Characteristics of Manufacturers

2.2.1 In-house Production

Manufacturers typically operate their own production facilities, which can range from small workshops to large industrial plants. These facilities are equipped with specialized machinery and technology tailored to specific manufacturing processes. For example, a manufacturer of electronic devices may have clean rooms, assembly lines, and testing laboratories to ensure that their products meet rigorous industry standards. In-house production allows manufacturers to maintain control over their operations, ensuring consistency in quality and efficiency.

2.2.2 Control Over Quality

One of the key advantages of manufacturers is their ability to implement comprehensive quality assurance practices. Manufacturers often establish quality management systems (QMS) that guide their operations. This includes setting quality standards, conducting regular inspections, and utilizing statistical process control (SPC) to monitor production processes. By controlling the entire production environment, manufacturers can quickly identify defects or deviations from quality standards and take corrective actions to minimize waste and improve product reliability.

2.2.3 Customization Capabilities

Manufacturers frequently offer customization options to meet specific customer needs. This flexibility allows them to create bespoke products tailored to individual specifications, which can range from minor modifications to entirely new designs. For instance, a manufacturer of industrial machinery may work closely with a client to develop a machine that fits unique operational requirements. This capability enhances customer satisfaction and loyalty, as clients feel their specific needs are being addressed directly.

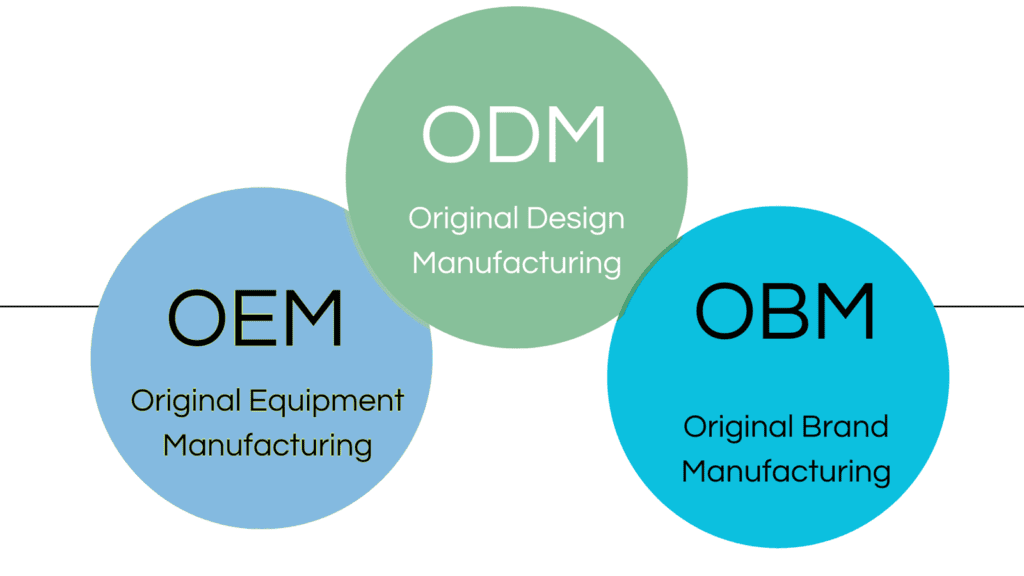

2.3 Types of Manufacturers

2.3.1 OEM (Original Equipment Manufacturer)

OEMs produce components or complete products that other companies brand and sell under their own names. For instance, a company may design a new smartphone, but the components—such as the screen and processor—are sourced from various OEMs. This arrangement allows brands to focus on marketing and branding while relying on OEMs for manufacturing expertise.

2.3.2 ODM (Original Design Manufacturer)

ODMs design and manufacture products based on their own specifications, which are then sold under another company’s brand. This type of manufacturer typically conducts market research, develops prototypes, and manages the entire design process. For example, a clothing retailer may partner with an ODM to create a new line of apparel that reflects current fashion trends.

2.3.3 Contract Manufacturers

These firms produce goods according to specifications provided by other companies, often at a lower cost than the contracting company could achieve in-house. Contract manufacturers are particularly prevalent in industries like electronics, where they may assemble complex devices based on designs provided by the original brand.

2.3.4 Custom Manufacturers

Custom manufacturers specialize in producing unique items tailored to specific client requirements. They often work on a project basis, providing specialized services such as tooling, fabrication, and assembly. For example, a custom manufacturer might create specialized equipment for a research lab.

2.3.5 Company with factory

As companies and industry continue to develop, many are expanding their operations by establishing full-process production capabilities. They are creating their own brands and developing in-house manufacturing facilities, enabling them to manage both production and sales through dedicated teams. This integrated approach allows them to enhance control over their products, streamline processes, and improve their market presence.

Traditionally, some factories were seen as solely production-focused, often lacking expertise in sales, marketing, and foreign languages, which made cross-border transactions challenging. However, many modern companies with their own manufacturing facilities now have dedicated foreign trade teams. These teams not only bridge communication gaps but also possess a strong understanding of the manufacturing process, enabling them to navigate international transactions effectively.

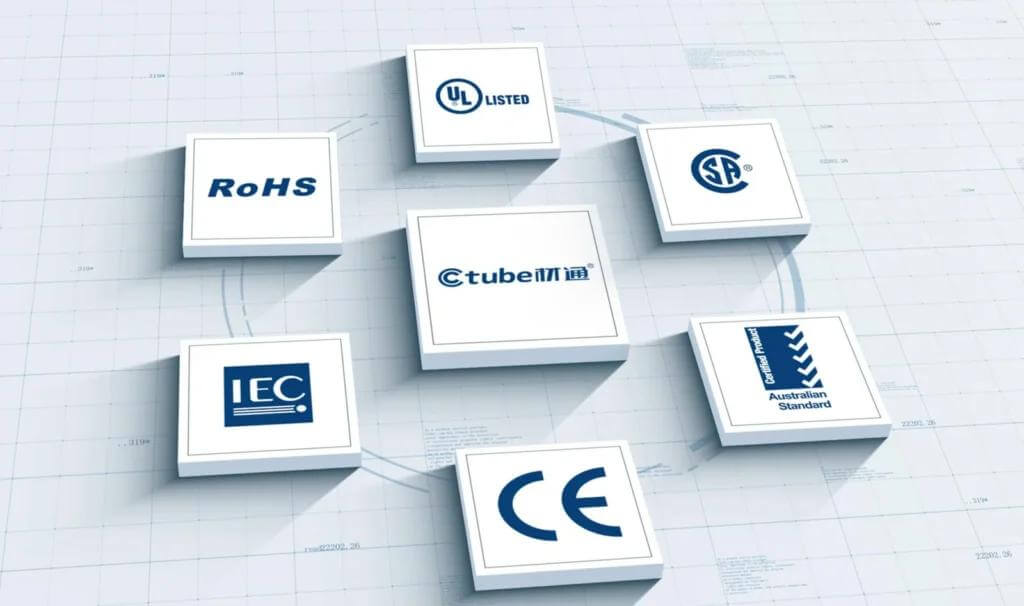

Ctube is the one among them. Guangdong Ctube Industry Co., Ltd. is a professional electrical conduit manufacturer and supplier based in Dongguan, Guangdong, China, Ctube is the brand name and has own factory to produce electrical conduit comply with different certifications and standard of different countries. Also accept custimization options.

2.4 Production Process

2.4.1 Sourcing Raw Materials

The first step in the production process involves sourcing high-quality raw materials needed for manufacturing. Manufacturers often build strong relationships with suppliers to secure favorable terms and reliable deliveries. This sourcing phase can involve rigorous vetting processes to ensure that materials meet quality and regulatory standards. Manufacturers may also engage in negotiating long-term contracts to stabilize supply and pricing, thereby minimizing the risk of production delays.

2.4.2 Manufacturing Process

Production Planning: Manufacturers create detailed production schedules based on demand forecasts, inventory levels, and resource availability. This planning phase is critical for optimizing operational efficiency.

Preparation and Setup: Before production begins, manufacturers prepare their machinery and workstations, ensuring that they are calibrated and equipped for the specific job at hand.

Production Techniques: The manufacturing process can involve various techniques, such as machining, welding, molding, or assembly. Each method requires specific equipment and skilled labor to ensure precision and quality.

Assembly: In cases where products consist of multiple components, assembly lines are often employed to streamline the process, allowing for systematic and efficient product construction.

2.4.3 Quality Assurance

Inspection: Regular inspections are conducted at different stages of production to identify defects early in the process.

Testing: Manufacturers may perform rigorous testing of raw materials and finished products to ensure compliance with safety and performance standards.

Certification: Many manufacturers seek certifications (e.g., ISO 9001) to demonstrate adherence to recognized quality standards, enhancing their credibility in the market.

2.4.4 Distribution

Once products are completed and pass quality inspections, they move into the distribution phase. Manufacturers may choose to handle logistics internally or partner with third-party logistics (3PL) providers.

Warehousing: Finished goods may be stored in warehouses until orders are fulfilled. Efficient inventory management practices are essential to avoid overstocking or stockouts.

Transportation: Manufacturers must coordinate transportation logistics to ensure timely delivery to customers or retailers. This may involve selecting shipping methods, managing freight costs, and ensuring compliance with shipping regulations.

Order Fulfillment: Effective order fulfillment processes ensure that customer orders are processed accurately and shipped promptly, contributing to overall customer satisfaction.

3. What is a Trading Company?

3.1 Definition of Trading Company

A trading company is a business entity that specializes in the buying and selling of goods rather than engaging in manufacturing. These companies act as intermediaries in the supply chain, connecting manufacturers with various types of buyers, including retailers, wholesalers, and end consumers.

Their primary function is to source products from multiple manufacturers, manage inventory, and distribute these products to market efficiently. By leveraging their extensive networks and industry expertise, trading companies simplify the procurement process for buyers and provide manufacturers with access to a broader market.

In the global marketplace, trading companies play a pivotal role by streamlining transactions, mitigating risks associated with international trade, and offering logistical support. This not only helps manufacturers reach wider audiences but also allows buyers to procure products without the complexities of dealing directly with multiple manufacturers.

3.2 Characteristics of Trading Companies

3.2.1 Intermediary Role

Trading companies serve as crucial brokers between manufacturers and buyers. They negotiate deals, handle contracts, and ensure that products are delivered in accordance with the terms agreed upon.

This intermediary function frees manufacturers to focus on their core competency—production—while trading companies manage sales, marketing, and distribution.

They facilitate communication and coordinate efforts between all parties involved, ensuring a smoother flow of goods and information.

3.2.2 Market Reach

One of the standout advantages of trading companies is their capacity to offer a diverse range of products from various manufacturers. This extensive market reach allows them to cater to different customer needs and preferences effectively.

By forming partnerships with multiple manufacturers, trading companies can create one-stop solutions for buyers seeking various products. This not only enhances the trading company’s value proposition but also provides a competitive advantage in the market.

3.2.3 Sales and Marketing Focus

Unlike manufacturers, trading companies place a significant emphasis on sales and marketing rather than production. Their primary objective is to market and sell products effectively. To achieve this, trading companies often employ dedicated sales teams and implement robust marketing strategies that include digital marketing, content creation, and customer relationship management.

This sales-centric approach enables trading companies to respond swiftly to market trends and changing customer demands, ensuring they remain competitive in dynamic business environments.

3.3 Types of Trading Companies

3.3.1 Import/Export Companies

Import/export companies specialize in facilitating international trade. They handle the logistics of importing goods from foreign manufacturers and exporting domestic products to international markets. Their activities encompass a range of functions, including coordinating shipments, managing customs documentation, and ensuring compliance with international trade regulations.

For example, an import/export company may source electronics from manufacturers in Asia, manage the complexities of international shipping, and distribute these products to retailers in North America.

3.3.2 Wholesale Distributors

Wholesale distributors purchase large quantities of goods directly from manufacturers and resell these products to retailers or other businesses. They typically maintain substantial inventories, providing essential services such as storage, order fulfillment, and transportation.

By buying in bulk, wholesale distributors can negotiate lower prices from manufacturers, which they then pass on to retailers, fostering increased sales and expanding market access for manufacturers. This relationship is particularly beneficial for small to medium-sized retailers that may lack the resources to purchase directly from manufacturers.

3.3.3 Operational Model

Trading companies operate with a distinct structure that prioritizes sourcing, inventory management, and strategic sales approaches:

Sourcing: Trading companies actively seek reliable manufacturers to partner with. This involves assessing suppliers based on various criteria, including product quality, pricing, and delivery reliability. Establishing solid relationships with manufacturers enables trading companies to offer competitive products that meet market demands.

Inventory Management: To meet customer needs and maintain optimal cash flow, trading companies maintain inventories of products sourced from various manufacturers. Effective inventory management involves closely monitoring stock levels, forecasting demand, and optimizing storage and logistics processes to reduce costs and enhance efficiency. Advanced inventory management systems and technology are often employed to track inventory in real-time, enabling trading companies to respond swiftly to changing market conditions.

Sales Strategies: Trading companies implement diverse sales strategies to reach potential customers effectively. This may include direct sales initiatives, digital marketing campaigns, participation in trade shows, and utilizing online marketplaces. By leveraging multiple channels, trading companies can enhance their visibility, attract a broader customer base, and drive sales.

4. Key Differences Between Manufacturers and Trading Companies

4.1 Production Capabilities

Manufacturers

Manufacturers typically operate from large production facilities equipped with specialized machinery and technology designed for mass production. These facilities often house advanced equipment such as CNC machines, assembly lines, molding machines, and robotics, which enable them to produce goods efficiently and at scale. The integration of technology such as automation and computer-aided design (CAD) systems further enhances their production capabilities, allowing for precision and quality control. As a result, manufacturers can create a diverse range of products, often tailored to specific customer requirements.

Trading Companies

In contrast, trading companies do not have production facilities. Instead, they rely entirely on third-party manufacturers to produce the goods they sell. This reliance on external suppliers means that trading companies must carefully vet and select manufacturers to ensure product quality and reliability. While trading companies can offer a wide range of products sourced from multiple manufacturers, they lack the ability to influence production processes directly. This can sometimes lead to challenges in product consistency and quality assurance.

4.2 Product Sourcing

Manufacturers’ Approach

Manufacturers often engage in direct procurement of raw materials necessary for their production processes. Establishing strong relationships with suppliers is vital for manufacturers, as it enables them to secure quality materials at competitive prices. These direct relationships can also lead to potential cost savings, as manufacturers can negotiate bulk purchasing agreements and long-term contracts, reducing overall production costs. By controlling their sourcing, manufacturers ensure that the quality of raw materials aligns with their production standards.

Trading Companies’ Approach

Conversely, trading companies source products from various manufacturers, which can impact product consistency and quality. They may not have direct relationships with raw material suppliers, as their focus is on the finished goods. This approach allows trading companies to offer a broader product range but can result in variability in product quality. When sourcing from multiple manufacturers, trading companies must ensure that the products meet the expectations of their customers, often relying on the reputation and quality assurance practices of the manufacturers they partner with.

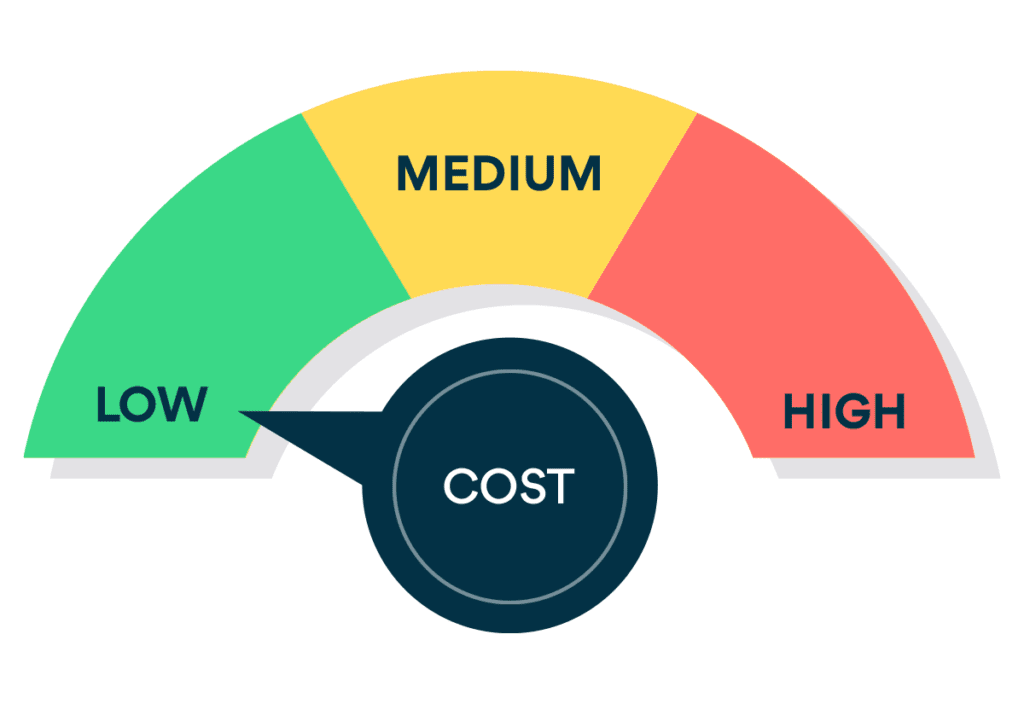

4.3 Pricing Structures

Manufacturers

Manufacturers face fixed production costs that include expenses related to labor, raw materials, equipment maintenance, and overhead. These costs influence the pricing of their products. Manufacturers often benefit from bulk pricing advantages due to economies of scale; the more they produce, the lower the per-unit cost. Factors such as material prices, labor costs, and manufacturing efficiency play significant roles in determining the final pricing of products. Consequently, manufacturers can often offer competitive pricing to their customers, especially for large orders.

Trading Companies

Trading companies, on the other hand, typically mark up prices to cover their costs and profit margins. Since they do not engage in production, their pricing structure reflects the added value of their services, including sourcing, logistics, and customer support. The markup can vary based on factors such as market demand, product availability, and the complexity of the supply chain. While trading companies may provide convenience and variety, their prices can be higher compared to direct purchases from manufacturers due to these additional costs.

4.4 Relationship with Customers

Manufacturers

Manufacturers often engage directly with customers, allowing for stronger relationships and better communication regarding product specifications, customization options, and after-sales support. This direct engagement enables manufacturers to understand customer needs and preferences, facilitating the development of tailored solutions. Additionally, manufacturers can offer bespoke products designed specifically for individual customers, enhancing their value proposition and customer satisfaction.

Trading Companies

In contrast, trading companies act as intermediaries between manufacturers and customers. While they provide valuable services such as product sourcing and logistics, this intermediary role can affect customer service and relationship management. Trading companies may not have the same level of insight into the manufacturing process as manufacturers do, which can limit their ability to address customer inquiries about product specifications or customization options. However, their extensive product offerings and market knowledge can still provide customers with a variety of choices and efficient purchasing solutions.

5. How to Identify Manufacturers and Trading Companies

Identifying whether a company is a manufacturer or a trading company can be crucial for businesses looking to source products effectively. Here’s a comprehensive guide to help you distinguish between the two by examining company backgrounds, product offerings, and communication practices.

5.1 Researching Company Backgrounds

5.1.1 Company Website

When investigating a company’s background, the first step is to analyze its website thoroughly. Here’s what to look for:

Production Capabilities: Manufacturers typically highlight their production processes, facilities, and the technology they use. Look for sections detailing their machinery, workforce, and production lines. In contrast, trading companies may focus more on their service offerings rather than their manufacturing capabilities.

Certifications: Check for certifications that indicate quality management and production standards. Look for mentions of certifications such as ISO 9001, which signifies adherence to international quality management standards.

Product Details: Manufacturers usually provide detailed product specifications, including dimensions, materials, and technical data. Trading companies, on the other hand, might showcase a wider variety of products with less technical information.

5.1.2 Industry Reputation

Understanding a company’s reputation within the industry is essential.

Customer Reviews and Testimonials: Research customer feedback on platforms like Google, industry forums, and social media. Positive reviews can indicate reliability and quality, especially for manufacturers.

Industry Presence: Look into the company’s participation in trade shows, industry associations, and forums. Manufacturers often engage in industry events to showcase their products, while trading companies may focus on networking and sales.

5.1.3 Certifications and Compliance

Certifications can offer insight into a company’s manufacturing capabilities and standards.

Common Certifications: Familiarize yourself with common certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and CE marking for product safety in Europe. These certifications can indicate a commitment to quality and compliance with industry standards, which are more typical of manufacturers than trading companies.

5.2 Evaluating Product Offerings

5.2.1 Analyzing Product Catalogs

A close examination of a company’s product catalog can provide valuable insights into its nature.

Signs of a Manufacturer: Look for detailed product specifications, production volumes, and customization options. Manufacturers usually provide comprehensive information, allowing customers to understand the production process and options available.

Indicators of Trading Companies: Trading companies often present a broader product range but with less detailed specifications. They may focus more on branding and marketing their products rather than providing in-depth production information. If you notice a catalog filled with various brands and general product descriptions, it may indicate a trading company.

5.3 Communication and Customer Service

5.3.1 Response Times and Support

The way a company communicates can also be telling.

Manufacturers: They may offer more personalized responses and technical support, as they possess deeper knowledge of their products and production capabilities. If you reach out for technical inquiries, a manufacturer is likely to provide detailed answers and solutions tailored to your needs.

Trading Companies: They might provide quicker responses but may lack the technical depth that manufacturers offer. Their focus is often on sales rather than technical support, which could affect the quality of information you receive.

5.3.2 Professionalism in Interaction

Assessing professionalism during initial communications can help gauge the company’s expertise.

Gauging Expertise: During your interactions, take note of the representatives’ ability to answer questions and provide insights into their products. Manufacturers typically display a higher level of expertise and product knowledge, as they are directly involved in the production process.

Depth of Product Knowledge: Engage in discussions that require technical understanding, such as inquiries about specific materials or manufacturing processes. A manufacturer should be able to provide detailed explanations, whereas a trading company may provide general information.

6. Tools and Resources for Distinguishing Companies

6.1 Online Directories and Databases

Online directories are invaluable for researching manufacturers and trading companies. Platforms like Alibaba and Made-in-China allow you to filter searches by criteria such as location, product type, and company size.

When reviewing profiles, pay attention to company histories, product offerings, and user reviews, which can provide insights into credibility and operational capabilities. Engaging directly with representatives through messaging or inquiries can clarify any uncertainties regarding their manufacturing processes and product availability.

6.2 Trade Shows and Expos

Attending industry-specific trade shows offers valuable networking opportunities where you can meet representatives from both manufacturers and trading companies. These events facilitate relationship building and provide insights into industry trends and innovations.

Additionally, observing product demonstrations and collecting samples allows you to assess quality and functionality firsthand, helping you make more informed distinctions between companies.

6.3 Third-Party Certifications

Recognizing industry certifications is crucial for understanding a company’s credibility and manufacturing capabilities. Certifications like ISO 9001 (Quality Management Systems), CE marking for European compliance, and UL listing for safety assurance indicate a commitment to quality and regulatory standards.

Familiarizing yourself with these certifications can help you distinguish reliable manufacturers from trading companies, ensuring that your sourcing decisions are based on trust and compliance with industry standards.

7. Conclusion

In today’s complex business landscape, distinguishing between manufacturers and trading companies is essential for making informed sourcing decisions. Manufacturers, with their in-house production capabilities, quality control measures, and customization options, play a crucial role in the supply chain. They offer the ability to ensure product quality and meet specific customer needs directly.

On the other hand, trading companies serve as valuable intermediaries, providing access to a broader range of products from various manufacturers. Their strengths lie in market reach and flexibility, enabling them to adapt quickly to changing consumer demands.

Ultimately, whether engaging with a manufacturer or a trading company, the key is to conduct thorough research, establish strong relationships, and prioritize quality assurance practices to foster long-term success.

Choose the right one for your needs, and good luck with your project!