PVC conduit is a popular choice for electrical conduits due to its cost-effectiveness, durability, and flexibility. Over the years, advancements in PVC conduit manufacturing technology have improved the quality and efficiency of PVC conduit production, making it an even more attractive option for contractors and electricians. In this article, we’ll explore some of the recent advancements in PVC conduit manufacturing technology and how these advancements are impacting the industry.

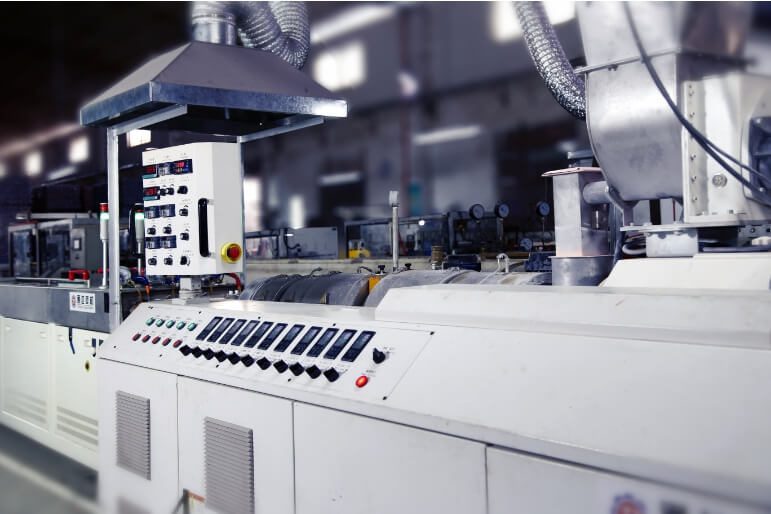

Extrusion Technology

One of the most significant advancements in PVC conduit manufacturing technology has been in the area of extrusion. Extrusion is the process of melting and shaping plastic materials into a continuous profile, such as a PVC conduit. In recent years, advancements in extrusion technology have improved the speed, accuracy, and consistency of PVC conduit production.

One such advancement is the use of co-extrusion technology. Co-extrusion involves the simultaneous extrusion of multiple layers of material, such as PVC and a protective outer layer. This technology allows for the production of PVC conduit with enhanced properties, such as increased UV resistance or improved impact resistance.

Another advancement in extrusion technology is the use of computer-controlled extrusion lines. These lines use advanced software and sensors to monitor and adjust the extrusion process in real-time, ensuring consistent production and reducing waste.

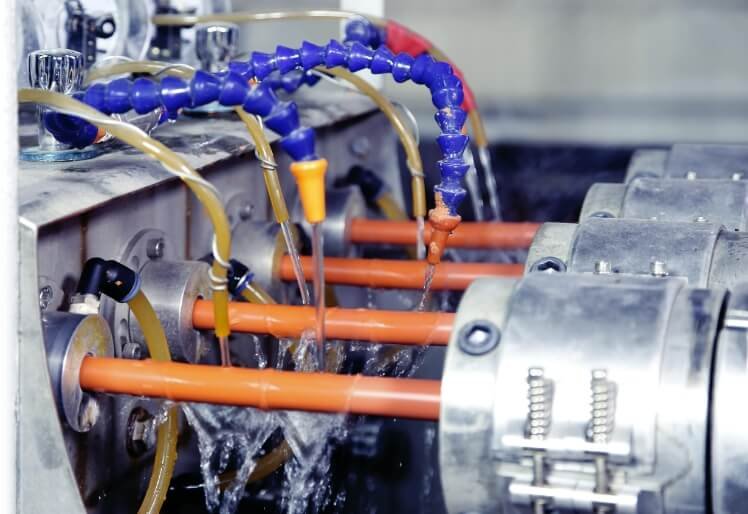

Injection Molding Technology

Injection molding is another manufacturing process used in the production of PVC conduit. This process involves melting plastic pellets and injecting them into a mold to create a specific shape. Advancements in injection molding technology have improved the precision, speed, and cost-effectiveness of PVC conduit production.

One such advancement is the use of multi-cavity molds. These molds allow for the simultaneous production of multiple PVC conduit pieces in a single injection molding cycle, increasing production efficiency and reducing costs.

Another advancement is the use of hot-runner systems. These systems keep the plastic pellets at a consistent temperature, reducing the amount of material waste and improving the quality of the final product.

Automated Manufacturing Systems

Advancements in automation technology have also impacted PVC conduit manufacturing. Automated manufacturing systems use robots and other advanced machinery to perform tasks such as material handling, assembly, and quality control.

These systems can improve production efficiency and reduce labor costs, while also improving the quality and consistency of the final product. For example, automated quality control systems use sensors and cameras to inspect PVC conduit products for defects, ensuring that only high-quality products make it to the market.

3D Printing Technology

While not yet widely used in PVC conduit manufacturing, 3D printing technology has the potential to revolutionize the industry. 3D printing involves the layer-by-layer production of three-dimensional objects using a digital model.

Advancements in 3D printing technology have improved the speed, accuracy, and range of materials that can be used in 3D printing. In the future, 3D printing could be used to create customized PVC conduit pieces or to produce complex shapes that would be difficult or impossible to create using traditional manufacturing methods.

Conclusion

Advancements in PVC conduit manufacturing technology have improved the quality, efficiency, and cost-effectiveness of production, making PVC conduit an even more attractive option for contractors and electricians. From extrusion and injection molding to automation and 3D printing, the future of PVC conduit manufacturing looks bright. As technology continues to evolve, we can expect to see even more advancements in the industry, further improving the quality and versatility of PVC conduit products.