La plupart des bricoleurs aimeraient lire des articles en ligne qui expliquent comment plier les conduits et tuyaux en PVC. Cela a du sens. Mais une chose dont ils n'ont pas parlé, est-ce correct ? Oui, nous ne pensons pas que plier les conduits et tuyaux en PVC soit correct. Nous avons donc décidé de parler de ce problème avant de commencer cet article.

Table des matières

BasculerPartie 1, Pourquoi nous ne recommandons pas de plier les conduits et tuyaux en PVC ?

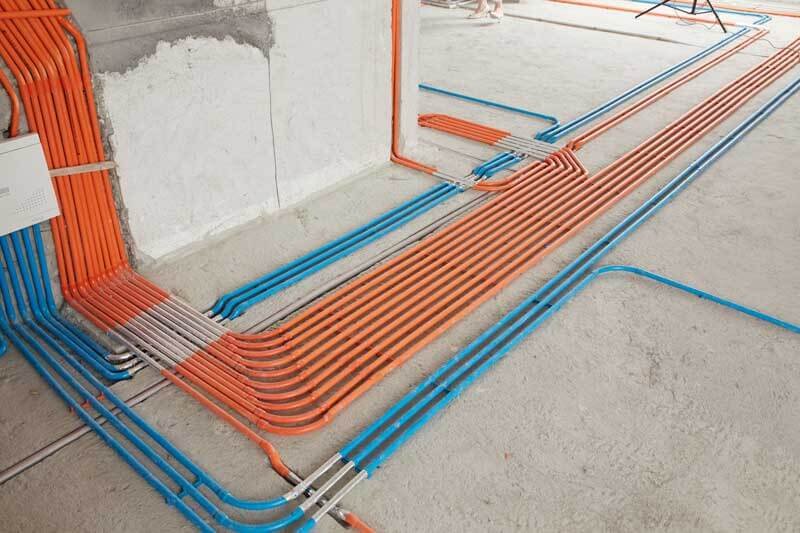

Les tuyaux en PVC sont divisés en deux fonctions : les tuyaux d'eau en PVC et les tuyaux de câbles électriques.

Le conduit en PVC est une sorte de tuyau rigide, qui est produit par un processus d'extrusion. Nous savons que l'épaisseur de la paroi du tuyau est parfaite car les matières premières sont chauffées uniformément pendant le processus d'extrusion et sont thermoformées dans le moule. Le pliage d'un tuyau en PVC, quelle que soit la méthode utilisée, est un chauffage local ou un pliage physique, presque équivalent à la destruction de la structure moléculaire uniforme de la zone d'origine, ce qui fragilise cette partie de la structure. Dans les cas graves, cela entraînera directement des fissures ou des fractures.

C'est pourquoi vous voyez que certains coudes sont blanchâtres car la force inégale provoque un changement d'épaisseur de la paroi, donc la partie blanchâtre est la plus fragile.

De plus, nous venons de mentionner deux utilisations différentes des conduites d'eau en PVC et des conduites électriques. Les conduites d'eau en PVC doivent résister longtemps à la pression de l'eau. Si elles sont enterrées directement sous terre, elles seront affectées par l'humidité et les micro-organismes. La partie la plus vulnérable supportera alors le poids de la fuite ou de la rupture de la conduite d'eau. Il en va de même pour le tube métallique en PVC. Si la meilleure partie n'est pas manipulée correctement et exposée à la lumière directe du soleil ou sous l'influence de l'humidité et des micro-organismes pendant une longue période, le fil fragile sera directement affecté. Combien de temps le fil peut-il durer ? Nous ne le savons pas.

La raison la plus importante est que la plupart des tuyaux pliés sont fabriqués par les ouvriers et qu'il y a des erreurs au cours du processus à long terme. La qualité du coude ne peut pas être garantie, par exemple si le coude après le coude est fissuré ou s'il est devenu blanc ? Ou l'angle du coude est-il suffisamment vertical ? En général, il y a des erreurs dans la mesure du niveau superficiel sur le chantier.

Partie 2, Comment plier un tuyau en PVC ?

Nous listons ici plusieurs méthodes de cintrage de tuyaux couramment utilisées pour votre référence afin que vous puissiez les utiliser temporairement lorsque cela n'est pas pratique ou qu'il manque de matériaux.

La première et la deuxième méthode ne nécessitent pas de cintreuse, tandis que la dernière nécessite une cintreuse de tubes dédiée.

Ressort de flexion

Avantages, bon marché et facile à utiliser

Inconvénients, le cintrage à froid physique, le corps du tube fera facilement blanchir la partie pliée et la rendra plus fragile.

Conseils de pro,

1. Retirez le ressort de flexion et testez le ressort lui-même pour voir s'il fonctionne bien.

2. Placez le ressort de manière à ce qu'il atteigne la partie où le tuyau doit être plié. Je vous suggère de mesurer à l'avance la taille de la partie où le tuyau doit être plié et de la marquer afin que les ressorts puissent être alignés. Alignez ensuite le milieu du ressort avec le centre du coude ;

3. Je vous conseille de porter des gants en coton pour travailler, ils sont plus antidérapants et peuvent protéger vos mains. À ce stade, pliez progressivement jusqu'à l'angle que vous souhaitez atteindre.

Il y a deux petites astuces dans la troisième étape de l'opération. La première consiste à utiliser la force et la décision au début pour s'assurer qu'il est facile de plier, mais la force derrière cela doit être douce pour que la partie pliée puisse être meilleure. Définissez la forme; la deuxième astuce est de tourner à l'angle correct (par exemple, 90°), ne lâchez pas immédiatement, maintenez cette position pendant 5 à 10 secondes, afin que la partie pliée puisse être mieux façonnée.

IlPistolet et sèche-cheveux

Avantages, bon marché et facile à utiliser

Inconvénients : il est facile de provoquer des problèmes en raison d'un chauffage excessif et le contrôle de la longueur et du degré de pliage n'est pas très précis. Et si le pistolet à air chaud chauffe un endroit pendant une longue période, il est facile de le déformer.

Mesures,

1. Mesurez la longueur du coude et marquez-la clairement ;

2. Préparez le pistolet thermique/sèche-cheveux ; une fois la température constante, vous pouvez commencer à chauffer la pièce ;

3. Après avoir été chauffé à une température spécifique, le tube du conduit devient mou et vous pouvez essayer de le plier à ce moment-là ;

4. Après avoir atteint l'angle de pliage prédéfini, arrêtez de chauffer et placez-le à l'air jusqu'à ce qu'il refroidisse et durcisse.

Conseils de pro,

1. Veuillez porter des gants en coton épais pendant toute l'opération pour protéger vos mains des brûlures ;

2. Vous pouvez utiliser des moules simples pour faciliter le façonnage et améliorer la précision ;

3. Lors du chauffage, ne vous approchez pas trop du tuyau et fixez une zone à chauffer. L'opération correcte consiste à secouer le pistolet thermique d'un côté à l'autre pour chauffer les environs du tube métallique (autour de l'endroit marqué), ce qui facilite le pliage du conduit et ne provoque pas de ramollissement excessif d'une zone. La situation ne peut pas être finalisée.

Cintreuse de conduits

Avantages, fonctionnement pratique, force plus uniforme

Inconvénients : coût plus élevé, besoin d'espace de stockage supplémentaire.

Mesures,

1. Déterminer la longueur et l'angle,

2. Faites une marque à l'emplacement correspondant, de préférence avec un marqueur

3. Connectez la cintreuse de tuyaux et mesurez la longueur et la position

4. Montez sur la cintreuse de tubes et l'autre bras vous aidera à ajuster correctement l'angle et la force de cintrage du tube.

Conseils de pro,

1. La cintreuse de tubes est utilisée dans la plupart des cas pour les tubes métalliques. Si vous pliez les tubes en PVC, vous pouvez utiliser des serviettes pour envelopper le mécanisme de fixation afin d'éviter de rayer les tubes ;

2. Faites attention à l'échelle sur la cintreuse de tubes avant utilisation et assurez-vous qu'elle a atteint la position désignée pendant le processus de cintrage du tube ;

3. Il est recommandé de porter des chaussures à semelles dures lors du pliage du tuyau pour éviter d'endommager la semelle ;

4. Si vous constatez une différence d'angle après avoir plié le tuyau, vous pouvez le corriger lentement à la main jusqu'à atteindre l'angle correct.

Partie 3, Comment faire passer un conduit dans les coins ?

Dans la plupart des cas, notre cintrage de tuyaux vise à rendre les tuyaux mieux installés dans le coin du mur et la position de l'arc. Donc, comme les coudes en PVC ne sont pas recommandés, comment pouvons-nous garantir l'installation ?

La solution est d'utiliser un coude ou une courbure. Il existe actuellement la plupart des angles disponibles sur le marché pour répondre aux besoins d'installation courants. Par exemple, des tailles couramment utilisées telles que 45°, 90° sont disponibles à l'achat.

Alors, quels sont leurs avantages par rapport à notre pliage direct ?

Premièrement, ces raccords sont thermoformés en une seule fois grâce au processus de moulage par injection, de sorte que la structure moléculaire est stable et qu'il n'y aura aucun danger caché comme des fuites ou des dommages causés par les différentes épaisseurs de paroi du coude ;

Deuxièmement, ils sont faciles à construire. Vous n'avez plus besoin de ces outils de pliage, et vous n'avez qu'à appliquer de la colle et connecter les raccords de tuyauterie pendant la construction. Si vous vous inquiétez de l'étanchéité, vous n'en avez pas besoin car les tolérances limitées des pièces ont été remplies de colle et le ciment lui-même est fait d'un matériau imperméable, qui est utilisé pendant longtemps sans fuite ;

Troisièmement, plus la construction est simple, plus les coûts de main-d'œuvre sont réduits. Par le passé, vous craigniez d'être un débutant et de ne pas savoir comment plier les tuyaux, et vous deviez toujours passer du temps à acheter des outils, à rechercher des outils ou à sous-traiter les travaux existants à une entreprise de décoration. Désormais, vous n'avez plus besoin d'y penser car la plupart du temps, vous n'avez plus besoin de considérer le travail de pliage des tuyaux. Il vous suffit de réfléchir à la manière d'agencer les conduits en PVC pour les rendre beaux et pratiques. Ce qui réduit également le temps de construction et vous permet d'économiser vos coûts.

En apparence, vous avez donc acheté des accessoires supplémentaires et dépensé de l'argent. Pourtant, cela en vaut la peine car ils sont très rentables en termes de construction et de fiabilité d'utilisation ultérieure.

Si les lecteurs sont intéressés par les raccords et accessoires de conduits, vous pouvez lire un article nous avons écrit sur l'introduction des accessoires.

Partie 4, Comment réaliser un coude et un pli qualifiés ?

Enfin, en tant que fabricant de tuyaux et raccords électriques en PVC, je voudrais expliquer brièvement le processus de production des raccords de tuyaux en PVC.

Du point de vue du processus, on peut le diviser grossièrement en dix processus suivants.

(1) Fabrication de moules

(2) Matériaux mélangés

(3) Matériaux de cuisson et réglage des paramètres de la machine d'injection

(4) Fermeture de la matrice

(5) Remplissage

(6) Maintien de la pression

(7) Refroidissement

(8) Ouverture et éjection du moule

(9) Post-traitement

(10) Contrôle de la qualité

Ces processus constituent presque tous des étapes de production nécessaires pour les produits moulés par injection. Cependant, la conception et la fabrication du moule, la qualité des matières premières, la technologie de moulage par injection et le débogage, ainsi que le contrôle qualité final sont les étapes les plus importantes pour garantir la qualité du produit.

Comme nous avons déjà écrit des articles similaires, je ne les répéterai pas ici. Les lecteurs intéressés peuvent cliquer pour consulter l'article « Tout ce que vous voulez savoir sur J Box »ou En savoir plus.

C'est tout. Merci pour votre temps et votre patience. N'hésitez pas à nous faire savoir si vous avez des questions sur nos produits et services. Vous pouvez nous contacter par Formulaire de contact à What's app sur la boîte à outils appropriée du site Web.