Tabla de contenido

Palanca1. What is Clear PVC Pipe ?

Clear PVC pipe is a specialized type of plastic tubing that merges the inherent benefits of polyvinyl chloride (PVC) with the added advantage of transparency.

Designed specifically for scenarios where visual inspection of the contents is crucial, clear PVC pipes are engineered to offer high clarity and exceptional durability. This makes them ideal for applications where seeing through the tubing is necessary, without compromising the tubing’s structural integrity or its chemical resistance.

The transparency of clear PVC pipe is achieved through a meticulous manufacturing process that ensures the material remains free of impurities and distortions, preserving its clear appearance. The tubing retains the robust physical properties typical of PVC, such as resistance to impact, pressure, and a variety of chemicals.

1.1 Common Types SCH 40 and SCH 80 Clear PVC Pipe

Here are two other popular models of clear PVC pipe: SCH 40 and SCH 80.

The following data is for reference only, as sizes may vary depending on the supplier’s production. Please confirm the exact dimensions with your supplier before purchasing.

1.2 Clear PVC Pipe Fittings

Clear PVC pipe fittings are connectors used with transparent PVC pipes to create a visually accessible piping system. These fittings offer similar strength and flexibility as standard PVC but with the added benefit of transparency. They are designed for easy integration with clear PVC pipes using solvent cement, which ensures a strong, leak-proof bond.

1.2.1 Clear PVC Pipe Coupler

Clear PVC pipe coupler is a straight fitting designed to connect two sections of clear PVC pipe, extending the length of a pipeline while maintaining transparency throughout. This coupler is ideal for applications where continuous monitoring of the flow is necessary, as it provides a seamless view of the liquid or gas moving through the pipes. Using clear PVC cement, the coupler bonds firmly to the pipes, creating a leak-proof and durable connection.

The transparent nature of the coupler allows for easy visual inspection of the bonding area and the internal flow, making it especially valuable in industries like chemical processing, aquariums, and food and beverage systems where cleanliness and integrity are paramount.

1.2.2 Clear PVC Pipe Elbow

The clear PVC pipe elbow is a 90/45 degree bent fitting that allows piping systems to change direction without compromising the flow. Its transparent body provides full visibility into the bend, making it easy to inspect for blockages or buildup that might occur in the corner. This elbow fitting is critical for applications where sharp directional changes are required, such as in tight installation spaces.

The smooth interior ensures minimal flow resistance, while the clear exterior aids in troubleshooting and maintenance. Whether used in industrial processing or aquaculture, the clear PVC elbow enhances the efficiency of piping systems by allowing real-time monitoring at key directional points.

1.2.3 Clear PVC Pipe Tee

A clear PVC pipe tee is a versatile fitting that forms a “T” shape, allowing a pipeline to split into two paths or merge two flows into one. The transparency of the fitting ensures that fluid or gas flow can be easily monitored in all three directions, making it an excellent choice for complex systems requiring multiple branch lines.

The clear PVC tee is often used in systems where constant visual inspection is necessary to ensure proper flow and to detect potential issues like blockages or contamination. It is widely employed in industries such as chemical processing, water treatment, and laboratory setups, where maintaining the integrity of the system is crucial.

1.2.4 Clear PVC Pipe Male Adapter

The clear PVC pipe male adapter is a fitting that connects clear PVC pipes to threaded components, typically valves or metal fittings, allowing for smooth transitions between solvent-welded and threaded connections. One side of the adapter features a smooth socket for bonding with clear PVC pipes, while the other end is threaded for easy attachment to female-threaded components.

Its transparency makes it simple to inspect the connection and the flow, ensuring that the bonding area and the transition point are secure. This fitting is particularly useful in applications where frequent disassembly or maintenance is required, such as in filtration systems or chemical processing, offering both flexibility and visibility.

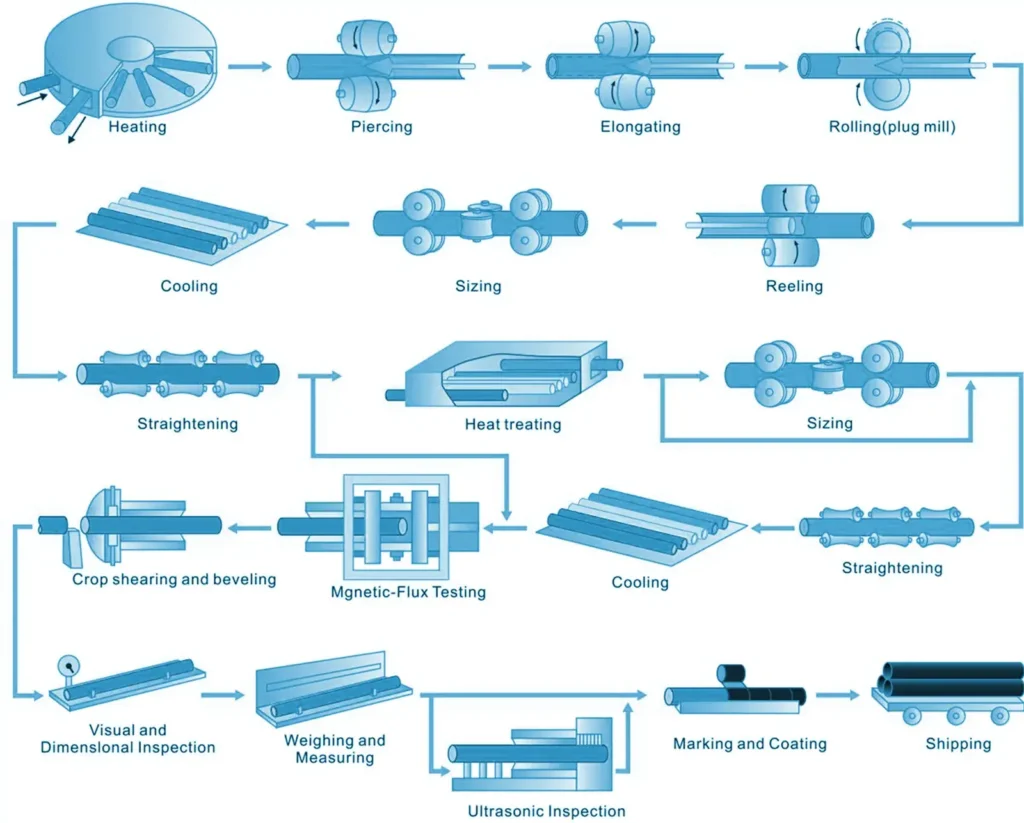

2. How to Make Clear PVC pipe?

Transparent PVC conduit or pipe is engineered by incorporating a high amount of plasticizer, along with a specific blend of stabilizers and other essential additives, into the PVC resin. This mixture is then extruded to create the final product.

Below is a brief overview of the production process for clear PVC pipe, which shares similarities with the manufacturing of clear PVC conduit.

2.1 Key Components of Transparent PVC Pipes Formulation

- PVC Resin: The base material providing the pipe’s strength and chemical resistance.

- Heat Stabilizer: Ensures the PVC does not degrade during the heating process.

- Lubricant: Aids in the smooth extrusion of the material, preventing it from sticking to the equipment.

- Plasticizer: Increases flexibility and helps achieve the desired transparency.

- Coloring Agent: Although used minimally, it can adjust the final tint of the pipe if required.

The formula design must meet specific technical requirements, including high transparency, moderate hardness, and sufficient strength.

2.2 Manufacturing Process of Transparent PVC Pipes

Step 1: Mixing of Transparent PVC Pipe Components

The components for transparent PVC pipes are mixed and heated to a temperature of 100~110°C, at which point the mixture is thoroughly blended and prepared for the next stage of processing.

Step 2: Extrusion and Granulation of Components

During extrusion and granulation, precise temperature control is essential. The highest temperature during this phase should exceed the material’s melting point but remain below the extrusion temperature for transparent PVC, typically between 155~160°C. The granulation process ensures thorough mixing and initial plasticization of the material, forming pellets ready for extrusion molding.

Step 3: Extrusion Molding of Transparent PVC Pipes

Extrusion molding is critical for determining the pipe’s final transparency. The extrusion temperature should be slightly higher than the granulation stage. Generally, within a specific range, higher molding temperatures result in better transparency.

Other factors influencing transparency include:

Traction Speed: Faster traction speeds (typically 10%~15% faster than the extrusion speed) contribute to improved clarity.

Cooling Rate: Rapid cooling enhances the tubing’s transparency. The cooling process starts with cold water spraying at the extrusion head, followed by immersion in a water tank.

Key Precautions During Extrusion

When directly extruding powder, the extrusion temperature should be about 5°C lower than when using granules. For larger diameter pipes, it is crucial to blow compressed air into the forming PVC pipe to maintain consistent diameter and stability. The pressure must be steady to avoid variations in tubing size or wall thickness. Additionally, maintaining a smooth and stable traction speed is vital to prevent dimensional inconsistencies.

Matters for attention: If production halts for an extended period, it is necessary to disassemble and clean the equipment thoroughly to prevent any decomposition of the PVC material.

Step 4: Cooling and Solidification

After the PVC pipes are shaped through extrusion molding, they undergo a cooling process to solidify the PVC into the final shape. The cooling process is controlled to ensure that the fittings maintain their intended dimensions and properties.

Step 5: Printing and Marking

Printing and Marking: PVC pipes may be printed or marked with important information, such as the manufacturer’s name, size, and pressure ratings. This helps users identify and install the tubings correctly.

3. The Pros & Cons of Clear PVC Pipe

3.1 Advantages of PVC pipes

3.1.1 Transparency

One of the key advantages of clear PVC pipe is its transparency, which allows for easy visual inspection of fluid flow or materials inside the pipe. This feature is especially valuable in industries like chemical processing and food production, where monitoring for blockages, contamination, or leaks is crucial for maintaining safety and quality control.

3.1.2 Versatility

The versatility of clear PVC pipes is another reason for their widespread use. Available in various sizes and thicknesses, these pipes can be adapted for multiple applications, including laboratories, water treatment facilities, aquariums, and even certain types of industrial processes. Their compatibility with a wide range of fittings allows them to be integrated into complex systems with ease.

This flexibility makes them an excellent choice for custom projects where specific dimensions and configurations are needed. Whether used in simple plumbing tasks or more intricate chemical processing systems, clear PVC pipes can be tailored to fit any requirement.

3.1.3 Flexibility, lightweight and easy installation

Clear PVC pipes are highly flexible, making them easy to cut, shape, and install. Their lightweight nature and adaptability allow for quick and efficient installation, reducing labor costs and time. This flexibility is particularly useful in settings where space is limited, or the system requires frequent adjustments.

Compared to heavier materials like metal pipes, they are easy to transport and install. For example, a 20-foot long, 4-inch clear PVC pipe can be easily carried by workers, whereas a five-foot-long iron pipe would require more effort and possibly multiple workers to handle.

3.1.4 Chemical Resistance

Clear PVC pipes are renowned for their excellent chemical resistance. They can withstand exposure to a wide range of chemicals, acids, and alkalis without degrading or losing structural integrity. This makes them highly suitable for use in chemical processing plants or any system where exposure to corrosive substances is a concern.

For instance, in industries handling hazardous chemicals, clear PVC pipes provide a safe and reliable option for transporting fluids without the risk of corrosion or leakage. This resistance extends the lifespan of the pipes and ensures consistent performance even in aggressive environments.

3.2 Disadvantages of PVC pipes

3.2.1 Limited UV Resistance

One of the primary disadvantages of clear PVC pipe is its limited resistance to ultraviolet (UV) light. Clear PVC is more susceptible to UV damage than regular PVC pipes, which can cause issues if the pipe is used in outdoor environments without proper protection.

Prolonged exposure to direct sunlight can result in discoloration, making the pipe turn yellow or cloudy. Over time, this exposure can also weaken the structural integrity of the pipe, leading to degradation, cracking, or reduced performance.

To mitigate these issues, it’s crucial to apply UV-protective coatings to clear PVC pipes used outdoors or, ideally, install them in indoor settings where UV exposure is minimal.

These coatings act as a barrier, preventing direct sunlight from damaging the pipe and preserving its clarity and durability. Another solution is to use clear PVC primarily in environments where UV exposure is not a concern.

3.2.1 Lower Temperature Tolerance

Clear PVC also exhibits lower tolerance to extreme temperatures when compared to other piping materials. In high-temperature environments, clear PVC can soften or even warp, making it less effective for applications requiring high thermal resistance. Similarly, in extremely cold conditions, the material becomes brittle, increasing the risk of cracks and fractures.

3.2.3 Higher Cost

The production of clear PVC pipes requires specialized processes that make them more expensive than standard PVC pipes. The increased cost is a significant factor to consider when choosing clear PVC for a project.

For some applications, the cost increase may not be justifiable, especially if the project doesn’t specifically require the visibility or chemical resistance that clear PVC offers.

However, for certain projects, the benefits of clear PVC—such as transparency for monitoring fluid flow or its chemical resistance properties—can outweigh the higher cost.

For instance, industries that require visual inspection of fluids, such as laboratories or chemical processing plants, may find that the cost increase is justified due to the improved functionality clear PVC provides.

3.2.4 Less Aesthetic Over Time

Aesthetically, clear PVC pipes are more prone to visible wear and tear compared to regular PVC. Over time, they can accumulate scratches, dirt, and grime, which can affect their transparency.

In applications where appearance is important, this loss of clarity can be a significant drawback. The pipes can become cloudy or stained, especially when exposed to harsh chemicals, frequent handling, or environmental factors such as dust and debris.

Frequent cleaning is necessary to maintain the clarity of clear PVC, especially in applications where visibility is essential. In some cases, regular maintenance may not be enough to preserve the pipe’s original look, and replacement may be required to maintain a clear, polished appearance.

For projects where aesthetics are a priority, the long-term maintenance and potential for discoloration should be carefully considered before selecting clear PVC pipes.

4. Applications of Clear PVC Pipe

Clear PVC pipes offer numerous advantages across a range of industries, making them an increasingly popular choice for various applications.

4.1 Industrial Applications

- Chemical Processing: In chemical manufacturing and processing facilities, clear PVC conduits allow operators to monitor the flow and condition of corrosive or hazardous chemicals. This visibility helps in detecting any issues such as clogs or leaks, and in ensuring the proper handling and flow of chemicals.

- Laboratories: Laboratories often use clear PVC conduits to observe fluid movements and reactions within experimental setups. This is particularly useful in experiments that involve mixing or transferring liquids, as it enables real-time monitoring of the process and helps in maintaining the integrity of the experiments.

- Pharmaceutical Industries: In pharmaceutical manufacturing, clear PVC conduits are used for processes that require close monitoring of the flow and quality of medicinal fluids. This transparency ensures that any contaminants or impurities can be detected early, thus maintaining the purity of pharmaceutical products.

4.2 Food and Beverage

- Food Processing Plants: Hygiene is paramount in food processing. Clear PVC pipes help in ensuring that the flow of food products, ingredients, or cleaning agents is unobstructed and visible, which aids in maintaining cleanliness and preventing contamination.

- Beverage Production: In breweries, distilleries, and water filtration systems, clear PVC pipes are used to monitor the flow and clarity of beverages and water. This allows for the early detection of any impurities or flow irregularities, ensuring the quality and safety of the end products.

4.3 Residential and Commercial Uses

- In buildings, clear PVC tubes are often employed for both aesthetic and practical reasons. They are frequently used in plumbing systems to offer a transparent view of the water flow, making it easier to spot potential issues such as blockages or leaks without dismantling the entire system. This can be particularly advantageous in home settings where maintenance and repairs need to be both efficient and minimally invasive.

- Additionally, clear PVC tubes are used decoratively in residential spaces. Their transparency allows for unique design possibilities, such as showcasing the tubing in stylish fixtures or integrating it into modern, open-concept interiors. This dual functionality of practicality and aesthetics makes clear PVC tubes a popular choice in home plumbing and design.

4.4 Agricultural Applications

- Irrigation Systems: Clear PVC pipes facilitate the monitoring of water flow in irrigation systems. This helps in ensuring that water and nutrients are evenly distributed to plants, optimizing growth and resource use.

- Nutrient Delivery: In hydroponic and other advanced agricultural systems, clear PVC pipes allow for the observation of nutrient solutions, ensuring that plants receive the right amount of nutrients.

5. Standards for Clear PVC pipes

5.1 ASTM International (American Society for Testing and Materials)

- ASTM D1785: This standard covers PVC pipes designed for pressure applications, including potable water distribution systems. It defines the dimensions, pressure ratings, and performance requirements for Schedule 40, Schedule 80, and Schedule 120 pipes.

- ASTM D2241: Focuses on pressure-rated PVC pipes for water supply. It specifies dimensions and performance requirements for pipes used in rural water systems, irrigation, and potable water distribution, emphasizing SDR (Standard Dimension Ratio) pipes.

5.2 ISO (International Organization for Standardization)

- ISO 1452: This international standard regulates the use of PVC pipes in water supply systems, both above ground and underground. It includes specifications for pressure piping systems made from unplasticized polyvinyl chloride (PVC-U) used for potable water transport.

- ISO 4422: Specifically targets PVC pipes used in drinking water distribution and supply under pressure. It ensures that the pipes meet performance and safety requirements for potable water applications.

5.3 ANSI/NSF Standards (American National Standards Institute / National Sanitation Foundation)

- ANSI/NSF 61: Regulates the health effects of materials used in water supply systems. This standard certifies that PVC pipes and fittings used in drinking water systems are safe for human consumption and do not leach harmful contaminants into the water.

- ANSI/NSF 14: Focuses on plastic piping system components, including PVC pipes and fittings, ensuring compliance with performance, pressure, and health standards for use in potable water systems.

5.4 AS/NZS Standards (Australia/New Zealand Standards)

- AS/NZS 1477: This standard covers PVC pipes and fittings for pressure applications in potable water supply systems in Australia and New Zealand. It includes specifications for pipes designed for water transport, irrigation, and pressure applications.

- AS/NZS 4020: This standard specifically tests the suitability of PVC materials for contact with drinking water, ensuring they are safe and non-toxic.

5.5 EN Standards (European Norms)

- EN 1452: This European standard specifies requirements for PVC piping systems used in water supply, including drinking water distribution under pressure. It covers both underground and above-ground systems and includes durability and pressure testing.

- EN 805: Provides general requirements for water supply systems using PVC piping, focusing on installation, operation, and maintenance for potable water supply networks.

5.6 CSA Standards (Canadian Standards Association)

- CSA B137.3: This standard covers pressure-rated PVC pipes used in potable water distribution and supply systems in Canada. It includes specifications for PVC pipe materials, dimensions, and performance, ensuring that they meet Canadian safety and performance requirements for water supply.

6. Clear PVC Pipe VS Clear PVC Conduit

Comparing some of the information above, we can understand that unlike clear PVC pipe, which is used for fluid transport, clear PVC conduit is specifically designed to house and protect wires and cables.

6.1 What’s Clear PVC conduit?

Clear PVC conduit, on the other hand, is designed for electrical wiring protection. Its transparency allows electricians and maintenance personnel to visually inspect the wiring inside, ensuring that it is in good condition and properly installed.

The transparency of the conduit also makes it easier to detect issues such as wire wear, overheating, or improper installation, thus reducing the risks associated with electrical faults.

Its design takes into consideration factors like insulation, resistance to impact, and the ability to perform under varying temperatures, which are essential for electrical systems.

6.2 What’s the Difference between Clear PVC Pipes and Clear PVC Conduit?

The standards and performance requirements for clear PVC pipes and clear PVC conduits (used for electrical purposes) differ significantly due to their distinct applications.

Clear PVC Conduit usually has thinner walls than pipes because it doesn’t need to withstand the same pressure levels. Its primary function is wire protection rather than transporting fluids. These are some of the key elements.

6.2.1 Flame-retardant for clear PVC conduit

Flame-retardant clear PVC conduit must meet specific standards to ensure safety and compliance in various electrical applications. The primary standard requirements for flame-retardant clear PVC conduit include:

- UL 94 Standard – The material should pass the UL 94 test, which classifies plastics based on their flammability. Clear PVC conduits often meet the V-0 rating, which ensures that the material stops burning within 10 seconds and does not drip flaming particles.

- ASTM D1784 – This standard covers rigid PVC compounds used for making pipes and fittings, including requirements for flame resistance.

- NFPA 70 / NEC – The National Electrical Code (NEC) specifies the use of flame-retardant materials in certain applications, including conduit installations, to reduce fire hazards.

- ISO 9772 – This international standard outlines methods for determining the flammability of plastic materials, including clear PVC conduit, under specific conditions.

6.2.2 Electrical insulation for Clear PVC Conduit

Electrical insulation standards for PVC conduit are crucial for ensuring safety, durability, and compliance in electrical installations. Here are key standards and regulations that apply to PVC conduits:

- National Electrical Code (NEC): The NEC, published by the National Fire Protection Association (NFPA), provides detailed requirements for electrical installations in the United States. It addresses the use of PVC conduit in Articles 352 and 353, covering aspects like insulation properties, installation methods, grounding, and protection from physical damage.

- ASTM Standards: ASTM D3485 covers testing procedures for determining the insulation properties of electrical conduit materials, including flame retardancy and electrical insulation performance.

- UL Certification: UL 514 covers electrical boxes and fittings, ensuring that conduit fittings meet insulation and safety standards.

- IEC Standards: IEC 61386 specifies the performance of conduit systems, including insulation resistance, dielectric strength, and material composition for electrical insulation.

- British Standards (BS): BS 7671 provides guidelines on electrical installation practices, including the use of PVC conduit in electrical insulation to prevent electric shock and protect wiring systems.

- ISO 1452: Focuses on pressure resistance and material properties, ensuring reliable insulation in various conditions.

7. Clear PVC Conduit vs. Traditional PVC Conduit

Since we’ve already covered the advantages, disadvantages, and applications of clear PVC pipes in detail, we won’t revisit the comparison with regular PVC pipes here. Instead, we’ll provide a brief comparison between clear PVC conduit and standard PVC conduit.

7.1 Transparency

As the name suggests, clear PVC conduit is transparent, allowing for visibility of the contents within the conduit. Regular PVC, often referred to as opaque PVC, is not transparent. Its primary purpose is functional rather than visual. It provides the same level of durability and protection but does not offer the benefit of visual inspection.

7.2 Impact Resistance

Clear PVC conduits have lower impact resistance compared to regular PVC. Regular PVC is typically more robust and impact-resistant. Its opaque nature often comes from a formulation designed to enhance its strength and durability. It is well-suited for applications where it may be subjected to physical stress or impacts.

For instance, Ctube’s AS/NZS 2053 rigid conduit series offers exceptional impact resistance, meeting stringent standards for both heavy-duty and medium-duty applications. The heavy-duty rigid conduit can withstand impacts up to 1250N, making it ideal for demanding environments requiring high durability. For medium-duty use, the rigid conduit is rated for impact resistance up to 750N, ensuring reliable performance in less extreme conditions.

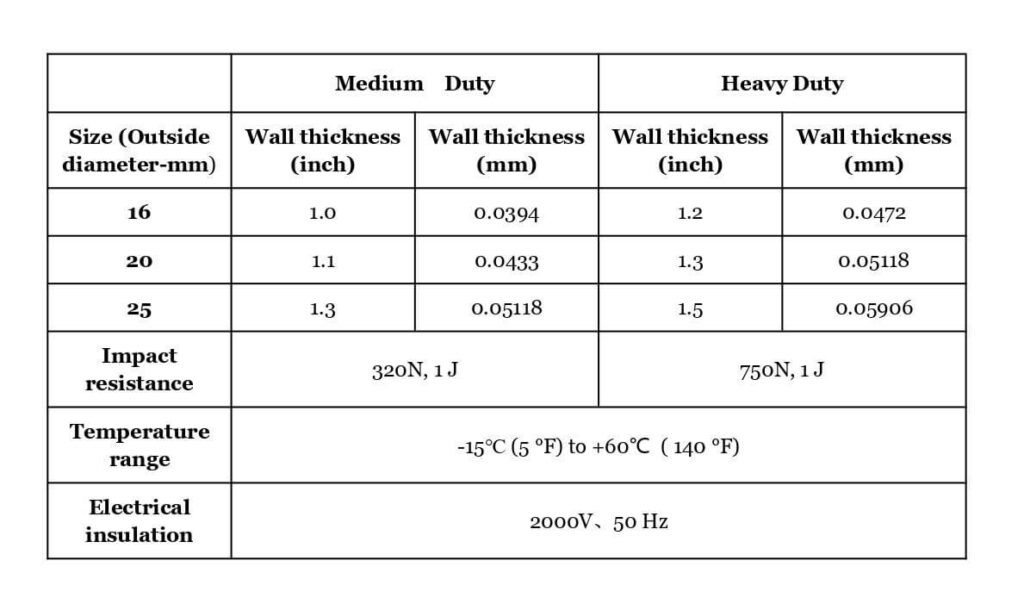

Additionally, Ctube’s clear PVC conduit is available in both heavy and medium-duty options. The heavy-duty clear PVC conduit provides impact resistance up to 750N, while the medium-duty variant withstands up to 320N, combining visibility with strength for various electrical installations.

7.3 UV Resistance

Clear PVC conduirts often has lower UV resistance compared to regular PVC conduits. Their transparency can make it more susceptible to UV degradation, leading to potential issues such as discoloration, brittleness, and reduced lifespan when exposed to sunlight or other UV sources. This exposure can lead to issues such as insulation damage, reduced performance, and even safety hazards like electrical shorts or fires.

Regular PVC conduits generally have better inherent UV resistance due to its opaque nature. The color and additives used in regular PVC conduits can provide some protection against UV radiation, helping to maintain their integrity and longevity in outdoor applications.

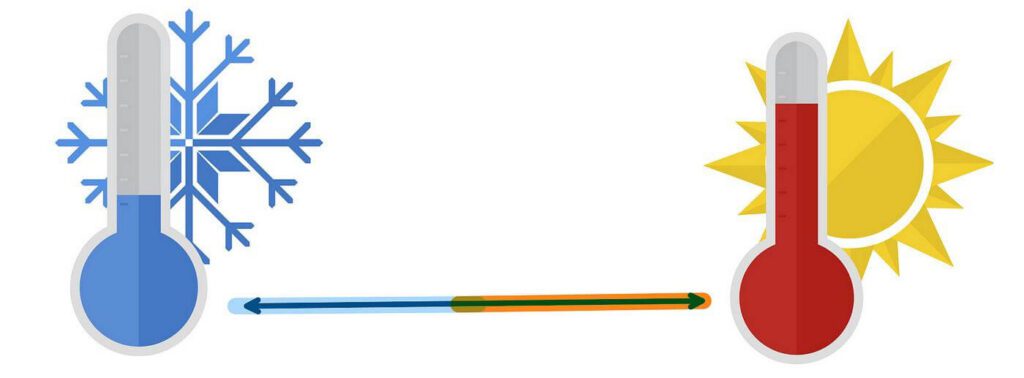

7.4 Temperature Resistance

Clear PVC conduits generally has similar temperature resistance to regular PVC conduits, but it can be more sensitive to extreme temperatures. Regular PVC conduits typically has good temperature resistance and can handle both high and low temperatures effectively.

For instance, Ctube’s AS/NZS 2053 rigid conduit is engineered to perform in a wide range of temperatures, withstanding extreme conditions from -15°C to 105°C. This makes it suitable for installations in both hot and cold environments, ensuring reliable protection for electrical systems in diverse climates.

In comparison, Ctube’s clear PVC conduit is designed for slightly lower temperature ranges, performing effectively from -15°C to 60°C.

7.5 Cost

Generally, clear PVC conduits are more expensive than regular PVC conduits. The production process for clear PVC conduits involves additional steps to ensure clarity and to maintain its optical properties, which contributes to the higher cost. The cost might also vary based on the diameter and thickness of the conduits.

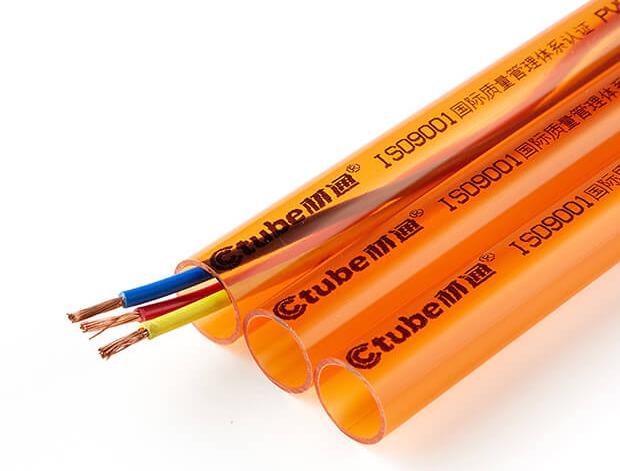

8. Ctube’s clear PVC conduit

Ctube is a China-based manufacturer of PVC conduit, pipes, and fittings, providing innovative solutions for construction projects. With ISO 9001, ISO 14001, and ISO 45001 certified manufacturing facilities, we ensure top-quality products and sustainable practices. Our products also carry global certifications like SGS, ROSH, CNAS, CE, and IEC, making them reliable for residential and industrial applications.

Ctube’s transparent PVC electrical conduits excel in environmental quality, flame retardancy, durability, and safety. Crafted from premium, eco-friendly materials that meet European 6P standards, these conduits are free from recycled content and adhere to IEC 62321-8:2017 testing standards. They also comply with the European V-0 flame retardant standard, quickly extinguishing fires without spreading or producing harmful debris.

Preguntas frecuentes

1. How do I join clear PVC pipes?

To join clear PVC pipes, the most common method is solvent cementing. This involves applying PVC primer and solvent cement to the pipe ends and inside of the fittings. After applying the cement, push the pipe into the fitting with a twisting motion, then hold it in place for a few seconds. Allow the joint to cure according to the manufacturer’s instructions before handling or pressurizing.

Alternatively, clear PVC pipes can be joined using threaded or compression fittings. For threaded connections, apply Teflon tape to the male threads and screw the fitting onto the pipe, tightening it securely with a wrench. Compression fittings provide a quick and adjustable connection by inserting the pipe into the fitting and tightening a nut to compress a ring against the pipe, creating a seal.

2. Why is clear PVC pipe expensive ?

Clear PVC pipe is more expensive primarily due to the manufacturing process and the materials involved. Unlike standard PVC, which is opaque, clear PVC requires more refined raw materials and higher levels of precision in production to ensure transparency.

This process often involves additional steps to remove impurities and prevent defects that could affect clarity, which drives up the cost.

Moreover, the demand for clear PVC is typically lower than regular PVC, making it a more specialized product with less mass production, further contributing to its higher price.

3. What are the common applications of clear PVC pipes?

Clear PVC pipes have several common applications across different industries due to their transparency and durability. In laboratory settings, they are frequently used for fluid transfer systems, allowing technicians to visually monitor the flow of liquids or gases. This transparency is crucial for detecting clogs, leaks, or contamination in the system.

In aquariums and aquaculture, clear PVC pipes are used for filtration and water circulation systems, enabling easy observation of water quality and flow. Additionally, in industrial processes, clear PVC pipes are employed where visual inspection of materials is critical, such as in chemical processing or food and beverage production, to ensure the integrity and safety of the system.