جدول المحتويات

تبديل1.Introduction

1.1 Brief Overview of Flexible Electrical Conduit

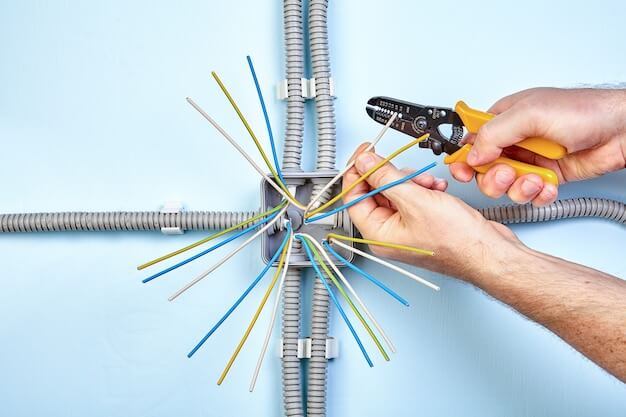

Flexible electrical conduit is an essential component in electrical installations, providing a protective pathway for electrical wiring. Unlike rigid conduit, flexible conduit can bend and twist to navigate around obstacles, making it ideal for installations in tight or complex spaces. This adaptability allows it to be used in residential, commercial, and industrial environments. It comes in various types, including Liquid-tight Flexible Metal Conduit (LFMC), Non-metallic Flexible Conduit, Flexible Metallic Conduit (FMC), and PVC Coated Flexible Conduit, each offering unique benefits and applications.

1.2 Importance of Cutting Flexible Conduit Correctly

Cutting flexible conduit correctly is crucial for ensuring a safe and reliable electrical installation. A precise cut helps maintain the integrity of the conduit, prevents damage to the internal wires, and ensures proper fitting of connectors and other components. Incorrect cutting can lead to sharp edges that may damage wires, improper fitting that compromises the installation’s safety, and increased risk of electrical hazards.

2. Different Types of Flexible Electrical Conduit You Need to Know

2.1 Liquid-tight Flexible Metal Conduit (LFMC)

Description: Liquid-tight Flexible Metal Conduit (LFMC) is a type of flexible conduit designed to offer robust protection against moisture and other contaminants while maintaining flexibility. It is commonly used in environments where exposure to liquids, oils, or chemicals is a concern.

2.1.1 Construction

– Core: The core of LFMC is typically made of galvanized steel or aluminum, which provides flexibility and structural integrity. The metal core is formed into a helical coil, which allows the conduit to bend and flex around obstacles.

– Outer Jacket: The outer jacket is made of a liquid-tight plastic or rubber material, usually PVC (Polyvinyl Chloride) or thermoplastic. This jacket is designed to prevent moisture, oils, and other contaminants from penetrating the conduit and reaching the electrical wiring inside.

2.1.2 Characteristics

– Liquid-tight: The primary feature of LFMC is its ability to prevent the ingress of liquids, making it suitable for wet or damp locations.

– Durable: The combination of a metal core and a protective outer jacket provides excellent durability and resistance to physical damage, corrosion, and environmental factors.

– Flexible: The helical design of the metal core allows the conduit to bend and flex, making it ideal for installations that require routing around obstacles or in confined spaces.

– Temperature Resistant: LFMC can withstand a wide range of temperatures, making it suitable for both indoor and outdoor applications.

2.1.3 Common Uses

– Outdoor Installations: LFMC is widely used in outdoor settings where exposure to rain, snow, or other moisture is a concern. It protects electrical wiring from water ingress, reducing the risk of electrical faults or short circuits.

– Industrial Environments: In industrial settings, LFMC is used to protect wiring from exposure to oils, chemicals, and mechanical stress. It is commonly found in manufacturing plants, refineries, and other industrial facilities.

– HVAC Systems: LFMC is often used in HVAC (Heating, Ventilation, and Air Conditioning) systems to route wiring alongside ducts and other mechanical components. Its flexibility and liquid-tight properties make it ideal for these applications.

– Machinery and Equipment: LFMC is used to connect electrical wiring to machinery and equipment that may be subject to vibration or movement. The flexibility of the conduit allows it to absorb vibrations and prevent damage to the wiring.

2.2 Non-metallic Flexible Conduit

2.2.1 Construction

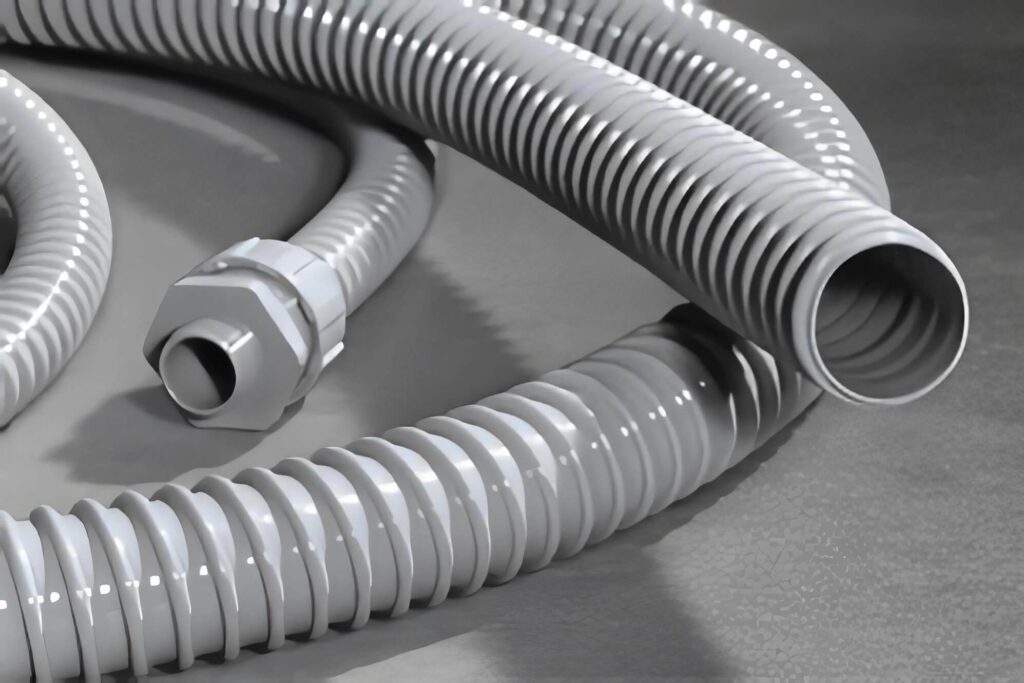

Non-metallic flexible conduit is primarily made from PVC (Polyvinyl Chloride) or other types of plastic materials. The construction typically involves:

– Material: PVC is widely used due to its flexibility, durability, and resistance to moisture and chemicals. Other plastics such as nylon or polyethylene may also be used depending on the specific application requirements.

– Coiled Design: The conduit is manufactured in a coiled or helical form, which allows it to bend and flex easily without the risk of kinking or breaking. This design facilitates smooth wire pulling during installation.

2.2.2 Characteristics

– Flexibility: Non-metallic conduit is highly flexible, allowing it to navigate around obstacles and through tight spaces without the need for elbows or fittings. This flexibility simplifies installation and reduces labor costs.

– Corrosion Resistance: Unlike metal conduits, non-metallic conduits are non-corrosive and do not rust or degrade over time. This makes them suitable for damp or corrosive environments without the need for additional protective coatings.

– Lightweight: The use of plastic materials makes non-metallic conduit lightweight, which facilitates handling during installation and reduces the overall load on support structures.

– Non-conductive: Plastic conduits are non-conductive and provide electrical insulation, minimizing the risk of electrical shock or short circuits. This is particularly important in environments where electrical safety is paramount.

– UV Resistance: Some grades of non-metallic conduit are UV-resistant, allowing them to be used in outdoor applications where exposure to sunlight may otherwise degrade the material.

2.2.3 Applications

Non-metallic flexible conduit finds widespread use across various industries and environments:

– Residential: In homes and apartments, non-metallic conduit is used for routing electrical wiring in basements, attics, and crawl spaces. Its flexibility and ease of installation make it ideal for retrofitting and renovation projects.

– Commercial: In office buildings, retail stores, and commercial spaces, non-metallic conduit provides a cost-effective solution for electrical installations where flexibility and durability are required.

– Industrial: Light industrial applications benefit from non-metallic conduit’s corrosion resistance and flexibility. It is used in workshops, manufacturing facilities, and warehouses to protect wiring from environmental hazards and mechanical stress.

– Outdoor: Certain grades of non-metallic conduit are designed for outdoor use, where they protect wiring from exposure to moisture, sunlight, and weather conditions. They are commonly used in outdoor lighting, landscaping, and irrigation systems.

2.3 Flexible Metallic Conduit (FMC)

2.3.1 Construction

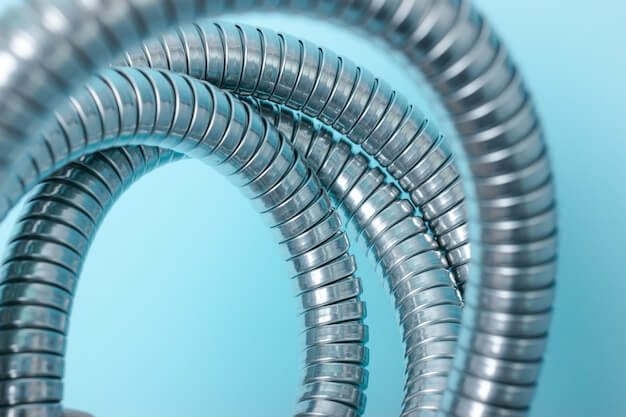

Flexible Metallic Conduit, also known as Greenfield or Flex, is a type of conduit used to protect electrical wiring in environments where flexibility and mechanical protection are required.

– Material: FMC is typically made from a helically wound strip of steel or aluminum, forming a flexible metal tube. The helical design allows the conduit to bend and twist while maintaining its structural integrity.

– Coating: Some FMC varieties may have a PVC or liquid-tight jacket for additional protection against moisture and contaminants, depending on the specific application requirements.

2.3.2 Characteristics

– Flexibility: FMC is highly flexible compared to rigid metal conduits, allowing it to bend around corners and obstacles without the need for elbows or fittings. This flexibility simplifies installation and reduces labor costs.

– Strength: Despite its flexibility, FMC provides robust mechanical protection for electrical wiring, shielding it from physical damage, impact, and abrasion.

– Temperature Resistance: FMC can withstand a wide range of temperatures, making it suitable for both indoor and outdoor applications where environmental conditions vary.

– Corrosion Resistance: While not as corrosion-resistant as non-metallic conduits, FMC’s metal construction provides adequate protection against most environmental factors.

2.3.3 Applications

Flexible Metallic Conduit is used in various industries and environments:

– Commercial and Industrial: FMC is commonly used in commercial buildings, manufacturing plants, and industrial facilities where wiring needs to be protected from mechanical stress and potential damage. It is suitable for installations in walls, ceilings, and floors where flexibility is required.

– Machinery and Equipment: FMC is used to protect electrical wiring in machinery and equipment that experience vibration or movement. Its flexibility allows wiring to move with the equipment without compromising safety.

– Indoor and Outdoor: Depending on the specific type and coating, FMC can be used indoors or outdoors to protect wiring from moisture, sunlight, and weather conditions.

2.4 PVC Coated Flexible Conduit

2.4.1 Construction

PVC Coated Flexible Conduit combines the flexibility of a metal conduit with the protective properties of a PVC coating. This type of conduit is designed to provide enhanced protection against environmental factors such as moisture, chemicals, and UV light, making it suitable for a variety of demanding applications.

– Core Material: The core of PVC Coated Flexible Conduit is typically made from a helical coil of steel or aluminum, which provides the conduit with its flexibility and mechanical strength.

– PVC Coating: The metal core is covered with a durable layer of polyvinyl chloride (PVC). This coating adds an extra layer of protection, making the conduit resistant to a wide range of environmental hazards.

2.4.2 Characteristics

– Flexibility: The helical metal core allows the conduit to bend and flex easily, making it suitable for installations in tight or complex spaces.

– Durability: The PVC coating provides excellent resistance to moisture, chemicals, oils, and other corrosive substances, extending the lifespan of the conduit.

– UV Resistance: The PVC coating also offers protection against UV light, preventing degradation when exposed to sunlight.

– Temperature Resistance: PVC Coated Flexible Conduit can withstand a broad range of temperatures, making it suitable for both indoor and outdoor applications.

2.4.3 Applications

PVC Coated Flexible Conduit is used in various environments, particularly where exposure to harsh conditions is a concern:

– Industrial Settings: Ideal for use in manufacturing plants, refineries, and chemical processing facilities where the conduit may be exposed to harsh chemicals, oils, and extreme temperatures.

– Outdoor Installations: Suitable for outdoor applications where the conduit is exposed to weather elements, including rain, sun, and varying temperatures.

– Marine Environments: The corrosion resistance of the PVC coating makes it suitable for use in marine environments where saltwater exposure is a concern.

– HVAC Systems: Commonly used in HVAC installations to protect wiring in areas where moisture and temperature fluctuations occur.

3. Tools and Materials Needed for Cutting Flexible Electrical Conduit

Cutting flexible electrical conduit accurately and safely requires the right tools and materials. Proper preparation ensures that the conduit is cut cleanly, preserving its integrity and making installation easier.

3.1 Essential Tools for Cutting Flexible Conduit

3.1.1 Conduit Cutter

– Description: A conduit cutter is specifically designed to cut through metal or non-metallic conduit cleanly. It usually features a ratcheting mechanism that makes cutting easier and more precise.

– Usage: Position the conduit cutter around the conduit, squeeze the handles, and rotate the cutter around the conduit to create a clean cut. The ratcheting action helps to apply consistent pressure, ensuring a smooth cut without deforming the conduit.

– Benefits: This tool is user-friendly, reduces the physical effort required, and ensures a clean cut, minimizing the need for further smoothing.

3.1.2 Hacksaw

– Description: A hacksaw is a versatile tool with a fine-toothed blade capable of cutting through metal and plastic. It is often used for cutting flexible metallic and PVC-coated conduits.

– Usage: Secure the conduit in a vise or clamp to prevent movement. Use long, steady strokes with the hacksaw to cut through the conduit. Ensure the blade remains straight to avoid angled cuts that can make installation difficult.

– Benefits: Hacksaws are widely available, inexpensive, and effective for a variety of cutting tasks. They provide a high level of control, allowing for precise cuts.

3.1.3 Utility Knife

– Description: A utility knife with a sharp blade is essential for cutting non-metallic flexible conduit and trimming any excess material after making the main cut.

– Usage: Score the outer jacket of the conduit with the utility knife before making a final cut. This helps guide the blade and prevents the jacket from fraying or tearing. Be sure to use a sharp blade to ensure a clean cut.

– Benefits: Utility knives are excellent for making precise, controlled cuts. They are also useful for a range of other tasks, making them a versatile addition to your toolkit.

3.1.4 Deburring Tool

– Description: A deburring tool is used to remove any sharp edges or burrs left on the conduit after cutting. Burrs can damage the wiring during installation and make the conduit difficult to handle.

– Usage: Run the deburring tool along the inside and outside edges of the cut conduit. This will smooth out any rough areas and prevent injuries or damage to the wiring.

– Benefits: Deburring tools improve safety and ensure a smooth, professional finish to your cuts. They help maintain the integrity of the conduit and protect wiring from abrasion.

3.1.5 Measuring Tape

– Description: Accurate measurements are crucial for ensuring that the conduit fits properly in the installation. A measuring tape helps you measure the exact length needed before cutting.

– Usage: Measure the length of conduit required for the installation and mark the cutting point clearly with a marker. Double-check your measurements to avoid mistakes.

– Benefits: Precise measurements prevent waste and ensure a perfect fit, reducing the need for adjustments and re-cuts.

3.1.6 Marker

– Description: A permanent marker is used to mark the conduit where it needs to be cut. This helps ensure precision and accuracy in your cuts.

– Usage: After measuring the desired length, use the marker to draw a clear, visible line around the conduit. This line will serve as a guide when cutting.

– Benefits: Markers are simple yet essential tools that provide clear visual guides, helping to ensure accuracy in your cuts.

3.2.1 Gloves

– Description: Protective gloves safeguard your hands from sharp edges and burrs on the conduit, as well as from potential cuts from the tools.

– Usage: Wear gloves at all times when cutting or handling conduit. Choose gloves that offer a good balance of protection and dexterity, allowing you to work safely without sacrificing precision.

– Benefits: Gloves protect your hands from injuries and improve grip, making it easier to handle tools and conduit safely.

3.2.2 Safety Glasses

– Description: Safety glasses protect your eyes from flying debris and metal shavings that can occur when cutting conduit.

– Usage: Always wear safety glasses when cutting conduit, especially when using power tools or a hacksaw. Ensure the glasses fit securely and comfortably to provide maximum protection.

– Benefits: Safety glasses prevent eye injuries and ensure you can work confidently without fear of debris causing harm.

3.3 Optional Tools for Better Efficiency

While the essential tools and safety equipment listed above are sufficient for most conduit-cutting tasks, certain optional tools can enhance your efficiency and make the job easier.

3.3.1 Pipe Vise or Clamp

– Description: A pipe vise or clamp holds the conduit securely in place while you cut, preventing it from moving and allowing for more precise cuts.

– Usage: Secure the conduit in the vise or clamp before cutting. This keeps the conduit steady, reducing the risk of slips or mistakes and making the cutting process safer and more efficient.

– Benefits: Vises and clamps provide stability, making it easier to achieve straight, accurate cuts. They also free up your hands, allowing for more controlled cutting.

3.3.2 Lubricant

– Description: Applying lubricant to the cutting blade or conduit can reduce friction and make cutting smoother, especially for metal conduits.

– Usage: Apply a small amount of lubricant to the cutting area or blade before starting. This helps reduce heat buildup and prolongs the life of the cutting tool.

– Benefits: Lubricants reduce wear on tools and conduits, ensuring cleaner cuts and extending the lifespan of your equipment.

By preparing adequately and following best practices, you can achieve precise cuts that maintain the integrity of the conduit and facilitate a smooth installation process. Whether you are working with liquid-tight flexible metal conduit (LFMC), non-metallic flexible conduit, flexible metallic conduit (FMC), or PVC-coated flexible conduit, the right tools and techniques will ensure a successful and safe project.

4. Step-by-Step Guide to Cutting Flexible Electrical Conduit

4.1 Selecting the Right Tool

Choosing the appropriate tool for cutting flexible electrical conduit is crucial for achieving clean and accurate cuts. The type of conduit being cut influences the tool selection.

4.1.1 Liquid-tight Flexible Metal Conduit (LFMC)

– Best Tool: A conduit cutter or hacksaw.

– Why: The metal core and liquid-tight jacket of LFMC require a tool that can handle both materials without causing damage.

4.1.2 Non-metallic Flexible Conduit

– Best Tool: A utility knife or conduit cutter.

– Why: Non-metallic conduits are typically made of PVC or other plastics, which are easily cut with sharp blades.

4.1.3 Flexible Metallic Conduit (FMC)

– Best Tool: A hacksaw or conduit cutter.

– Why: FMC’s metal construction requires a tool that can navigate the coiled structure without crushing or deforming it.

4.1.4 PVC Coated Flexible Conduit

– Best Tool: A conduit cutter or a hacksaw with a lubricated blade.

– Why: The combination of metal and PVC requires a tool that can handle both materials efficiently.

4.2 Positioning the Conduit

Properly securing the conduit ensures a straight cut and prevents movement that could lead to inaccurate or jagged edges.

4.2.1 Using a Pipe Vise or Clamp

– Place the conduit in a pipe vise or clamp it securely to a stable workbench.

– Tighten the vise or clamp to hold the conduit firmly in place.

4.2.2 Alternative Methods

– Holding by Hand: If a vise or clamp is not available, hold the conduit firmly with one hand while cutting with the other. This method is less stable and may not be suitable for all types of cuts.

– Using a Bench or Table Edge: Rest the conduit on the edge of a bench or table, using your body weight to keep it stable while cutting.

-1024x818.jpg)

4.3 Making the Cut

4.3.1 Using a Conduit Cutter

– Place the conduit cutter around the conduit at the marked point.

– Tighten the cutter and rotate it around the conduit until the cut is complete.

– Tips: Apply steady pressure and ensure the cutter’s blade is sharp for clean cuts.

4.3.2 Using a Hacksaw

– Position the hacksaw blade on the marked point.

– Use long, even strokes to cut through the conduit.

– For metal conduits, ensure the blade is suitable for cutting metal.

– Tips: Lubricate the blade if cutting PVC-coated conduits to reduce friction.

4.3.3 Using a Utility Knife

– Score the conduit along the marked line with the utility knife.

– Continue scoring until the conduit can be bent and snapped cleanly.

– Tips: Use a sharp blade and apply even pressure to avoid jagged edges.

4.4 Smooth Rough Edges with a Deburring Tool

– Run the deburring tool along the cut edges to remove any burrs or rough spots.

– Ensure the edges are smooth to prevent damage to wires or injuries during installation.

4.5 Finishing the Cut

4.5.1 Inspecting the Cut for Smoothness

– Check the cut edges for any remaining rough spots or burrs.

– Ensuring the cut is smooth helps in the proper installation of the conduit and prevents potential damage to the wiring.

4.5.2 Checking the Cut Length for Accuracy

– Measure the cut conduit to ensure it matches the required length.

– If necessary, make additional cuts or trim the conduit to achieve the precise length needed.

.jpg)

5. Conclusion

Cutting flexible electrical conduit accurately and safely is an essential skill for any electrical installation project. We began by discussing the importance of selecting the right tools, emphasizing that the type of conduit influences the tool choice—whether it’s a conduit cutter, hacksaw, or utility knife. Proper positioning of the conduit using a vise or clamp ensures stability and precision during the cutting process.

Practicing these techniques will improve your proficiency and confidence in handling flexible conduit. Whether you’re a professional electrician or a DIY enthusiast, mastering these steps will ensure your electrical installations are efficient and reliable.

As a over 10 years pvc conduit manufacturer in China, we are dedicated to delivering high-quality PVC conduit and fittings that meet stringent certification standards and undergo rigorous testing.

Our PVC flexible conduit meets relevant certification standards and passes rigorous testing, offering a wide range of colors and sizes. Our low smoke halogen-free and photovoltaic solar series have been upgraded through formulation for enhanced performance: the low smoke halogen-free series does not produce toxic substances when burned, and the photovoltaic solar series is more resistant to outdoor ultraviolet rays.

If you have any project requirements, please contact us.

الأسئلة الشائعة

1.Can I use regular scissors to cut flexible conduit?

No, regular scissors are not suitable for cutting flexible conduit. They lack the strength and sharpness required to cut through materials like metal or thick PVC. Using improper tools can result in uneven cuts and potential damage to the conduit. Instead, use tools specifically designed for cutting conduits, such as a conduit cutter, hacksaw, or utility knife.

2.What should I do if the conduit is too hard to cut?

If the conduit is too hard to cut, ensure you are using the appropriate tool for the material. For metal conduits, use a hacksaw or a high-quality conduit cutter designed for metal. If using a hacksaw, make sure the blade is sharp and suitable for cutting metal. Applying lubricant can also help reduce friction. For thick PVC or other non-metallic conduits, a sharp utility knife or a conduit cutter should suffice. If the conduit remains difficult to cut, consider using power tools designed for tougher materials, such as a reciprocating saw with the appropriate blade.

3. How can I ensure a straight cut every time?

To ensure a straight cut every time, follow these steps:

1. Measure and Mark Accurately: Use a measuring tape to measure the length of the conduit needed and mark the cutting point clearly with a marker.

2. Use a Guide: For precise cuts, use a cutting guide or a piece of scrap wood to guide your saw or cutter.

3. Secure the Conduit: Firmly secure the conduit in a vise or clamp to prevent movement during cutting.

4. Steady Hand and Consistent Pressure: Apply steady, even pressure while cutting, and use smooth, controlled motions with your tool.

5. Check and Adjust: After cutting, use a deburring tool to smooth out any rough edges and ensure the cut is straight and clean. If necessary, make minor adjustments to achieve a perfect cut.

4. What is the difference between cutting flexible conduit and rigid conduit?

The flexibility that makes flexible conduits so versatile also presents a significant challenge during cutting. When attempting to cut flexible conduit, it tends to move, twist, and collapse, which can result in an uneven or imprecise cut. Ensuring a clean cut requires extra care to keep the conduit as steady and round as possible. The conduit must be clamped or held securely in place, often using multiple points of contact to minimize movement. To mitigate movement, some operators also use a pipe cutter with a built-in clamp that stabilizes the conduit during the cutting process.

Rigid conduits do not bend easily. This inflexibility means that once positioned, they stay put, which is advantageous during the cutting process. Rigid conduits are typically straight, allowing for easy measurement and marking before cutting.