Table of Contents

Toggle1. Overview of Conduit Bending

1.1 Definition and Importance of Conduit Bending

Conduit bending is the process of shaping conduit pipes to route electrical wiring efficiently through a building’s layout, accommodating walls, ceilings, corners, and other structural features. Properly bent conduits are not only crucial for maintaining the safety of electrical systems but also play a significant role in keeping projects visually neat and accessible for future maintenance or upgrades.

The importance of accurate conduit bending extends beyond protection—it also impacts project efficiency, aesthetics, and safety. By creating smooth, precise bends, electricians can minimize unnecessary strain on wires, prevent damage caused by sharp edges or improper angles, and ensure that wiring paths comply with building codes. Well-executed bends make it easier to pull wires through conduits and reduce potential hazards associated with loose or exposed wiring.

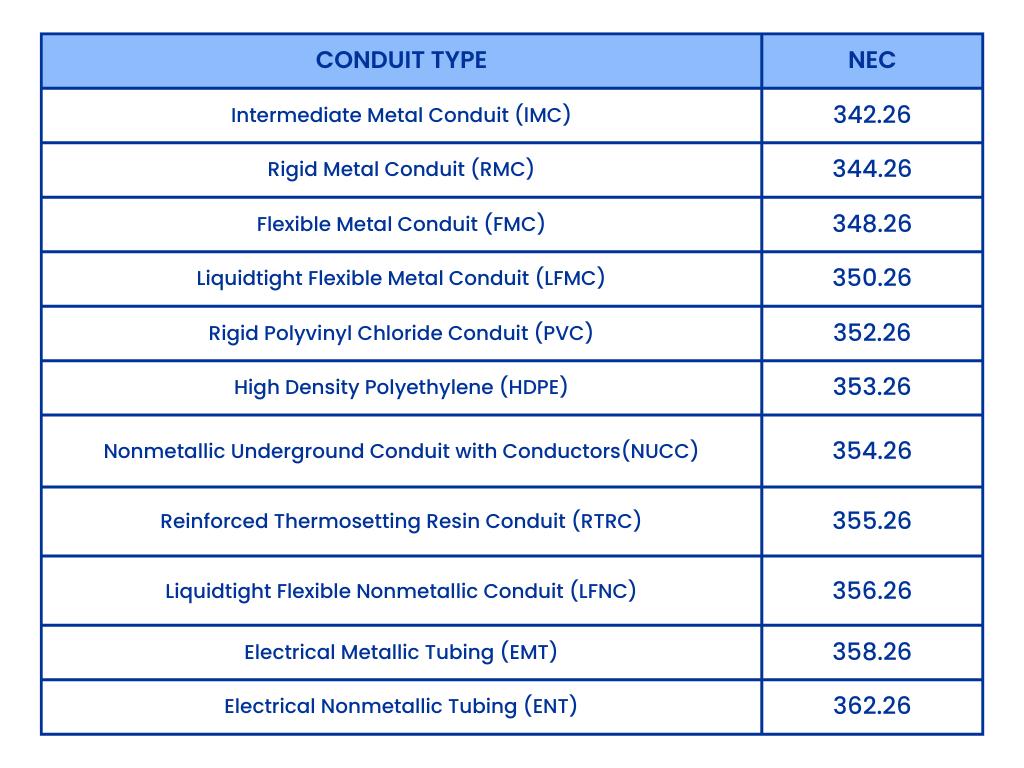

However, it’s important to bend the conduit in accordance with the relevant regulations. The NEC sets limits on the total number of bending angles allowed, and for reference, the following chart outlines the specific requirements for different types of conduit.

Generally speaking, National Electrical Code (NEC) mentioned that there shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.

1.2 Several Types of Commonly Bent Electrical Conduits

Electrical Metallic Tubing (EMT): Lightweight and easy to bend, EMT is commonly used indoors, particularly in commercial and industrial buildings. Its thin-walled metal construction provides adequate protection in controlled environments and can be bent manually or with electric benders.

PVC Conduit: Made from polyvinyl chloride, this conduit type is corrosion-resistant and ideal for outdoor or damp environments. PVC conduit can be heated and shaped to fit specific bends, making it versatile for both indoor and outdoor installations, especially where moisture resistance is important.

Rigid Metal Conduit (RMC): As a heavy-duty conduit with thick walls, RMC is robust and suitable for high-stress or exposed environments, such as industrial facilities or outdoor installations. RMC provides strong protection but requires more powerful benders, like hydraulic or electric models, to create accurate bends.

Understanding the characteristics of different conduit types and selecting the appropriate bending technique for each ensures both durability and safety in any electrical setup.

1.3 Importance of Choosing the Right Bender

Choosing the right conduit bender is crucial for accuracy, efficiency, and safety. Each type of conduit, due to its unique material properties and thickness, demands a specific bending approach. For instance, EMT’s flexibility allows it to be bent easily with manual or electric benders, while RMC’s rigidity requires the added force of hydraulic or electric benders to achieve precise angles without damaging the conduit. Additionally, PVC conduits, which are brittle when cold, require heating before bending to prevent cracks.

We will make a detailed introduction for different types of conduit bender and make comparison in the followings.

2. Types of Conduit Benders and Their Uses

2.1 Bending Spring

Bending springs are a helpful tool designed specifically to assist with bending non-metallic, flexible conduits like PVC conduit. By inserting a bending spring inside or around the conduit, it reinforces the walls of the conduit during the bending process, preventing it from collapsing or kinking. This is particularly useful when working with smaller-diameter PVC conduits, which can be prone to deformation when bent manually.

Best Applications: Bending springs are commonly used for light-duty, flexible conduits in residential or light commercial electrical installations. They are ideal for projects requiring smooth, gradual bends where heavy machinery or high-precision tools are not needed.

Advantages: Bending springs are lightweight, affordable, and easy to use. They provide additional support to achieve consistent bends without damaging the conduit, making them practical for quick, on-the-job adjustments and smaller installations.

Disadvantages: While effective for lighter materials, bending springs have limitations. They are generally only suitable for smaller, non-metallic conduits, as they may not provide adequate support for thicker or rigid materials like metal conduit. Additionally, bending springs require some manual effort, which may not be practical for larger projects or when precise angles are essential.

2.2 Hand and Mechanical Conduit Benders

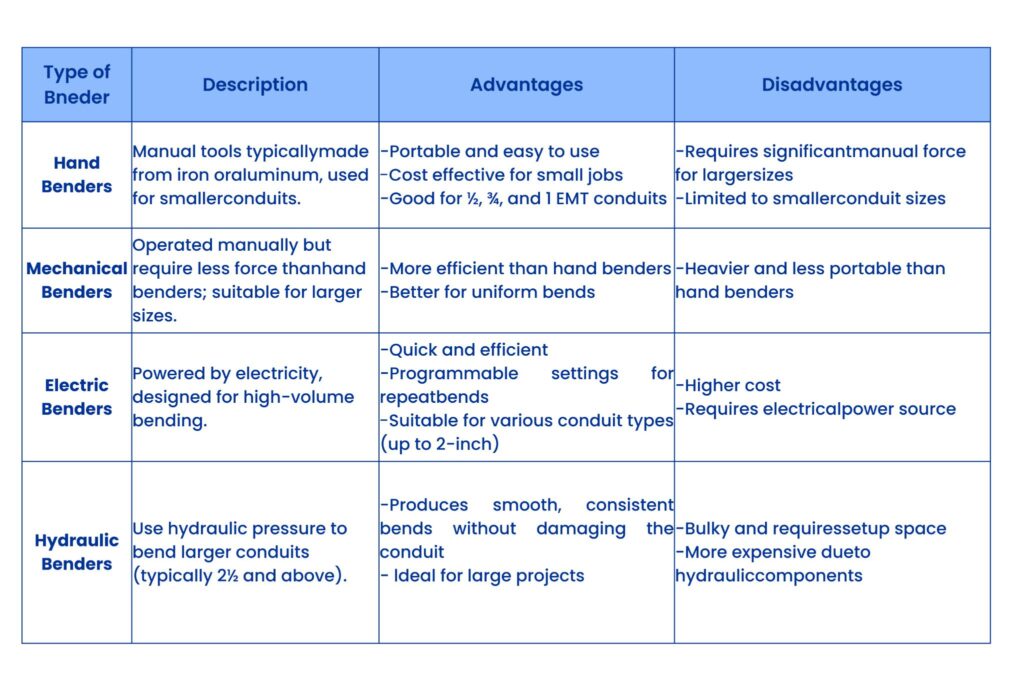

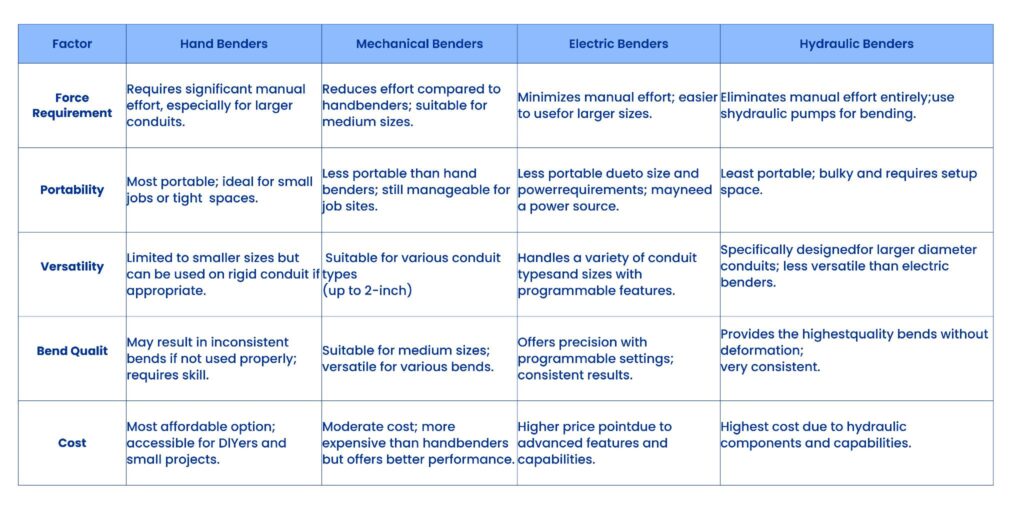

Hand and mechanical conduit benders are commonly used tools in electrical work for creating bends in various types of conduits. Both types offer a versatile solution for shaping conduits to meet the layout and design needs of electrical systems, though they differ in operation and ideal applications.

●Hand Conduit Benders

Hand conduit benders are traditional, manually operated tools that allow electricians to bend conduit using their own physical force. They typically include a lever and a radius die to help guide the conduit through simple bends, such as 90-degree angles or slight curves. Hand benders are lightweight, portable, and ideal for projects where only a few bends are required.

Best Applications: Hand benders are well-suited for bending smaller, lighter conduits, such as Electrical Metallic Tubing (EMT) and small-diameter Intermediate Metal Conduit (IMC). These materials are frequently used in residential and light commercial settings where the electrical layout may only require basic bends.

Advantages: These benders are affordable, easy to carry, and require no electricity, making them ideal for smaller projects. They are user-friendly and effective for situations where intricate bending precision is not necessary.

Disadvantages: They require physical effort to operate, which can become tiring when handling larger or thicker conduit types. Hand benders may not be suitable for Rigid Metal Conduit (RMC) or other thick-walled conduits that require more force to bend.

●Mechanical Conduit Benders

Mechanical conduit benders use mechanical assistance, such as a ratcheting mechanism or other leverage features, to increase the force applied, making them effective for bending thicker or larger-diameter conduits. They often incorporate built-in guides and angle indicators to aid in making precise bends and are suitable for more demanding applications.

Best Applications: Mechanical benders are commonly used for bending larger conduit sizes or heavy-duty materials, such as Rigid Metal Conduit (RMC) or larger Intermediate Metal Conduit (IMC). They are useful for commercial or industrial settings where more complex bending layouts are needed.

Advantages: They require less physical exertion than hand benders and offer greater control and precision. Mechanical benders are better suited for situations where repeatability and accuracy are crucial, particularly in complex or high-stakes electrical installations.

Disadvantages: Mechanical benders are generally more expensive, bulkier, and require more setup time than hand benders. Additionally, they may not be as convenient for quick, simple bends in lightweight conduits.

2.3 Electric Conduit Benders

Electric conduit benders automate the bending process using motors, allowing for faster and more precise bends with minimal physical strain. These benders work by engaging a motor that applies the necessary force to bend the conduit, allowing electricians to achieve consistent, high-quality bends with ease. The automation of the process eliminates the need for manual effort, making it an ideal solution for larger-scale projects where speed and accuracy are crucial.

●Best Applications

Electric benders are best suited for mid-range conduit sizes and thicker materials, making them ideal for commercial, industrial, and large-scale residential projects. They work efficiently on conduits such as Electrical Metallic Tubing (EMT), Intermediate Metal Conduit (IMC), and some sizes of Rigid Metal Conduit (RMC). Electric benders are especially useful for tasks that involve a high volume of repetitive bending, such as wiring installations in commercial or industrial buildings, where precision and speed are key.

●Advantages

One of the major advantages of electric conduit benders is the speed and precision they offer. These benders provide consistent, accurate bends, which is especially important for larger or more complex projects where uniformity is essential. The automation of the bending process also reduces physical strain on the user, allowing electricians to complete the task more efficiently and with less fatigue. Electric benders are ideal for repetitive bending tasks, helping increase productivity and reduce the risk of human error. For large-scale projects where multiple conduits need to be bent at specific angles, electric benders can save significant time compared to manual methods.

●Disadvantages

Despite their advantages, electric benders come with a few drawbacks. The most notable is the higher upfront cost. These benders are generally more expensive than manual models, making them a larger investment for small projects or individual contractors. Additionally, electric benders are less portable than manual benders, as they require a stable power source and can be bulky to transport. In environments where power supply is unreliable or unavailable, the dependence on electricity can be a significant limitation. Lastly, while electric benders are faster and more precise, they may lack the flexibility to adjust quickly to a variety of bends without some setup time, particularly for smaller, less standardized conduit materials.

2.4 Hydraulic Conduit Benders

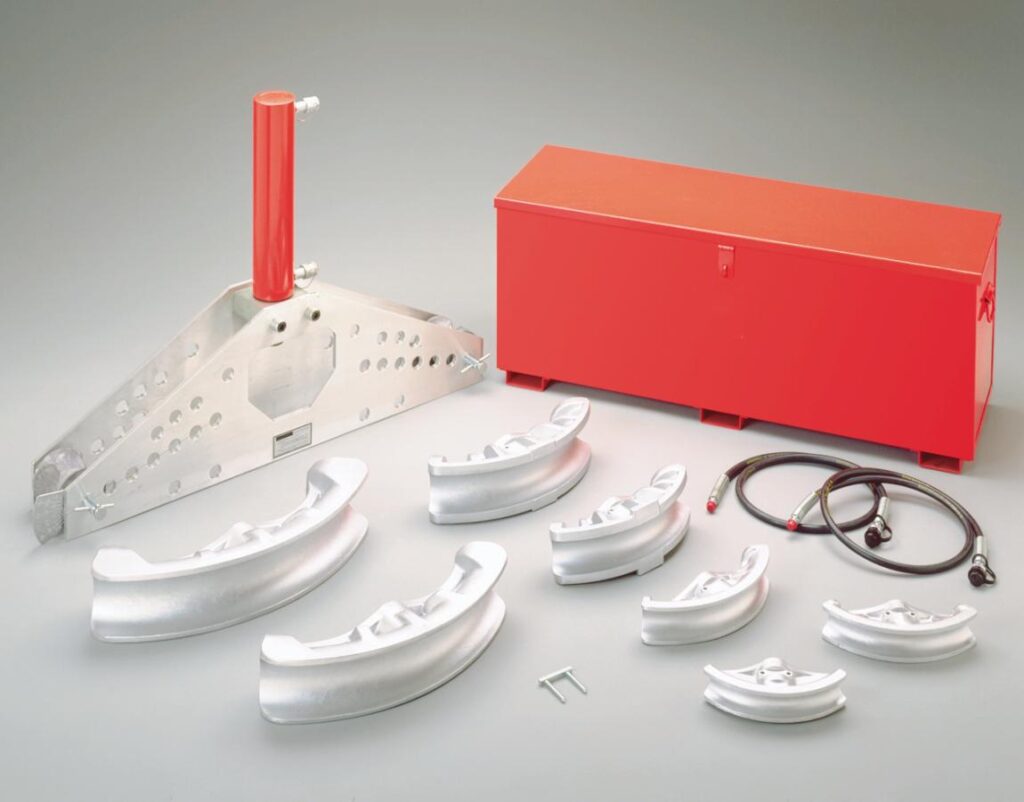

Hydraulic conduit benders operate using pressurized fluid to power the bending process, offering significant force to bend thick, rigid conduit materials. These benders use hydraulic pumps to apply controlled pressure to a bending die, allowing the conduit to be shaped with high precision. The hydraulic mechanism makes it possible to bend large and tough conduit types, such as Rigid Metal Conduit (RMC), without compromising the integrity of the material. This makes hydraulic benders the go-to tool for heavy-duty conduit bending tasks that require significant force.

●Best Applications

Hydraulic benders are ideal for industrial-grade applications, where heavy-duty conduits such as large-diameter RMC or thick-walled steel conduit need to be bent with precision. These benders are commonly used in large-scale industrial installations, outdoor construction projects, and manufacturing environments where robust conduits are essential to protect cables from physical damage and environmental factors. Hydraulic benders are also well-suited for projects involving tough materials that cannot be bent easily with manual or electric benders, such as heavy-duty or extra-thick conduits used in power plants, factories, and large commercial complexes.

●Advantages

The primary advantage of hydraulic conduit benders is their ability to bend very thick and heavy-duty materials with ease. The hydraulic system provides powerful force, enabling smooth and precise bends in rigid conduit that would be challenging to achieve with manual or electric benders. The resulting bends are consistent and professional, ensuring the integrity of the conduit is maintained and that the electrical installation remains safe and effective. Hydraulic benders are particularly beneficial for creating large-radius bends, which are often required for complex routing in industrial environments. Additionally, hydraulic benders are designed for durability, able to withstand heavy use over extended periods, making them an excellent investment for high-volume or large-scale projects.

●Disadvantages

While hydraulic benders excel in heavy-duty bending, they come with several disadvantages. First, they are expensive compared to manual and electric benders, making them a significant investment. Additionally, hydraulic benders are generally stationary, requiring a stable power source and a fixed location to operate. This limits their portability and makes them more suitable for workshops or fixed job sites rather than on-the-go or smaller-scale applications. Due to their size and complexity, hydraulic benders also require more space and maintenance, adding to both upfront and long-term costs. Their reliance on hydraulic fluid can also lead to potential maintenance needs and the risk of leakage, which may require specialized care to ensure optimal performance.

2.5 Specialty Benders (e.g., PVC Conduit Benders)

Specialty benders are designed for specific conduit materials, offering customized solutions for bending non-metallic conduits, such as PVC. For example, heated PVC benders use controlled heat to soften PVC conduit, allowing it to be bent without cracking or deforming. These benders are particularly effective for applications requiring smooth, precise bends in flexible or non-metallic conduits, providing an alternative to traditional mechanical bending methods.

●Best Applications

Specialty benders like heated PVC benders are ideal for projects that require customized shapes or precise angles in PVC conduit. This includes residential, commercial, and industrial installations where PVC conduit is used for its durability, lightweight, and non-corrosive properties. Heated PVC benders are commonly used in plumbing, low-voltage wiring, and electrical systems where the conduit must navigate around tight corners or complex spaces, creating custom curves that ensure proper conduit routing.

●Advantages

The primary advantage of specialty benders is their ability to bend flexible and non-metallic conduits like PVC without causing cracks or distortions. By using heat to soften the material, these benders ensure smooth, consistent bends that preserve the integrity of the conduit. This flexibility makes them ideal for jobs that require highly customized conduit shapes, where precise bends are crucial for meeting project specifications. Additionally, these benders are perfect for creating bends in conduit that would otherwise be difficult or impossible to achieve with traditional manual or electric benders.

●Disadvantages

One of the main disadvantages of specialty benders is that they are limited to specific materials, primarily PVC or similar non-metallic conduits. As a result, these benders cannot be used for metal conduits like EMT or RMC. Furthermore, many specialty benders require additional heating tools or setups, adding complexity and cost to the process. The need for proper temperature control and heating equipment also introduces the potential for inconsistency in the bending process, especially if the heating is uneven or the conduit is not properly prepared. Additionally, these benders are not as portable as manual models and often require a power source or specialized setup, limiting their use to specific job sites.

3. How to Choose the Right Bender for Different Conduit Sizes and Materials

3.1 Consider the Size & Material of the Conduit

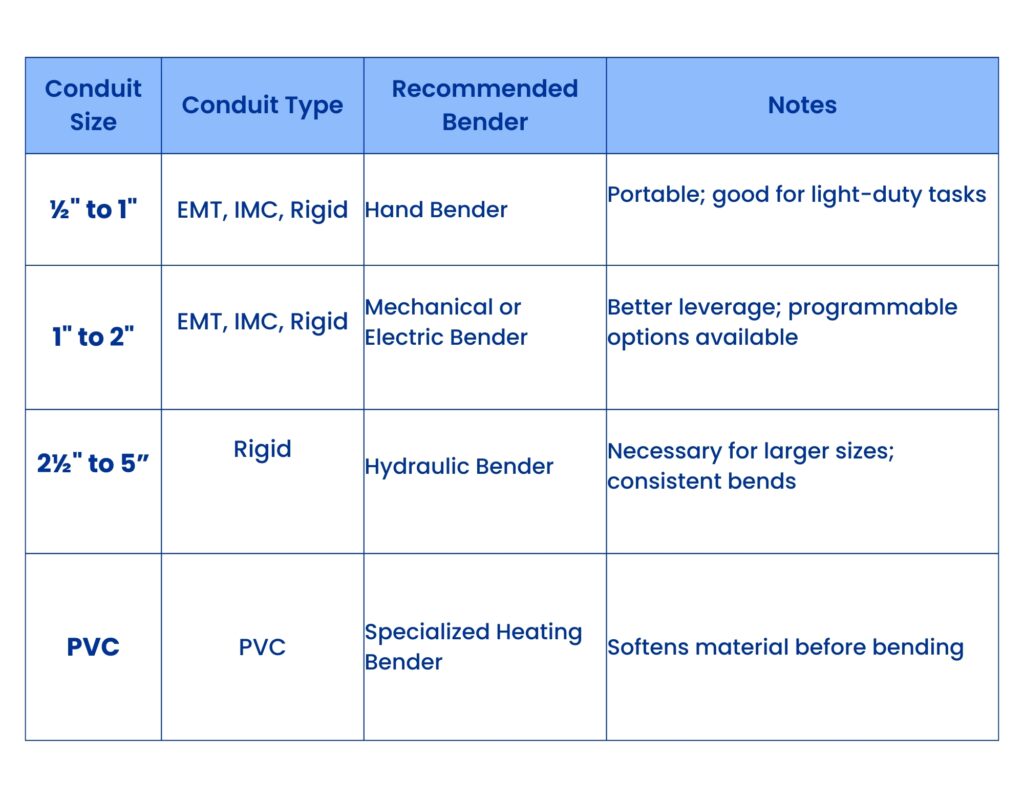

●Small Conduits (1/2 – 1 inch)

Small-diameter conduits, such as those between 1/2 inch and 1 inch in diameter, are generally lightweight and easier to handle. For these conduits, a manual bender is often sufficient, as they do not require excessive force to bend. Manual benders are portable, affordable, and easy to use, making them ideal for bending EMT (Electrical Metallic Tubing) and smaller-sized IMC (Intermediate Metal Conduit) commonly found in residential or light commercial settings. Using a manual bender for these smaller sizes allows electricians to control the bend closely and create smooth, accurate angles.

●Medium-Sized Conduits (1 – 2 inch)

Conduits ranging from 1 to 2 inches in diameter are heavier and require more force to bend than smaller conduits. While a manual bender could technically handle some of these sizes, electric conduit benders are often a better choice. Electric benders provide the additional power needed for medium-sized conduits, making bending easier and faster, especially when multiple bends are required. They offer precision and speed, which is valuable on larger projects, such as commercial installations, where time and accuracy are critical. Electric benders can handle EMT, IMC, and smaller RMC (Rigid Metal Conduit) within this size range, offering a practical solution for medium-duty applications.

●Large Conduits (2 inch and Up)

Large-diameter conduits, typically 2 inches or more, are extremely rigid and require significant force to bend without damaging the material. Hydraulic benders are the best choice for these large conduits, as they use pressurized fluid to apply consistent, high force, ensuring smooth, precise bends. Hydraulic benders are commonly used in industrial and heavy commercial projects where large RMC or other thick-walled conduit materials need to be bent to specific angles. These benders are powerful enough to handle the most demanding tasks, though they tend to be stationary and are usually set up in workshops or fixed locations on job sites.

3.2 Project-Specific Considerations

●Scale of the Project

The scale of the project significantly impacts the type of conduit bender needed. For small residential projects, manual benders are often sufficient due to the smaller conduit sizes (typically 1/2” to 1”) and lighter workloads. These projects usually require fewer bends, making a manual bender both practical and economical.

On the other hand, large industrial or commercial projects involve larger conduit sizes and higher volumes of bending, where electric or hydraulic benders are better suited. Industrial projects often involve thicker materials and larger-diameter conduits, which require the additional power and durability offered by hydraulic or electric benders. For these large-scale applications, choosing the right bender can save time, reduce physical strain, and ensure consistent results across repetitive bends.

●Budget and Available Workspace

Project budgets and the workspace available can also guide the choice of bender. Manual benders are the most affordable option and are portable, making them ideal for smaller budgets or projects where space is limited. These benders can be stored easily and used in confined spaces without the need for power sources or special setups.

However, if the project budget allows, electric benders provide a balance of affordability and enhanced capability, offering speed and precision for medium-duty applications. For larger projects with more extensive budgets and dedicated workspace, hydraulic benders can be a worthwhile investment due to their high power and efficiency with large conduits. Hydraulic benders typically require more setup space and are less portable, so they are best suited to larger work environments where they can be used as stationary equipment.

●Level of Precision Required

The level of precision required in the project is also a deciding factor. If aesthetics or tight angles are important, such as in visible installations or architectural projects, electric and hydraulic benders can deliver precise, consistent bends, reducing the likelihood of rework. These benders offer finer control and reduce errors, making them ideal for projects where accuracy is critical.

For projects where appearance and precision are less important—such as utility conduits hidden in walls or underground—manual benders may be sufficient. However, for installations with visible conduits, especially in commercial settings where aesthetics and uniformity matter, investing in a bender that provides precision and consistency is often worth the additional cost.

4. Techniques for Accurate Conduit Bending

4.1 Understanding Key Terms in Bending

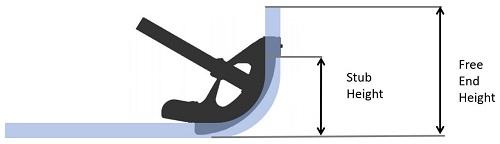

●Stub-Ups

A stub-up refers to a vertical bend at the end of a conduit, typically used to bring the conduit up to a specific height, such as from the floor to an electrical box or outlet. This bend is critical in applications where the conduit must emerge from a flat surface to connect with other components. Achieving an accurate stub-up bend ensures proper alignment and reduces the need for additional adjustments.

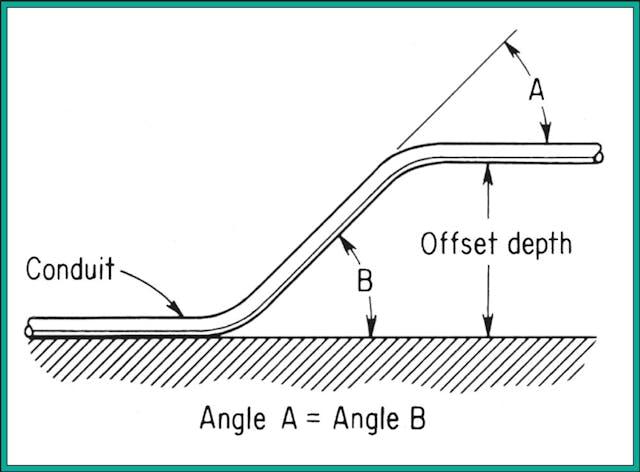

●Offsets

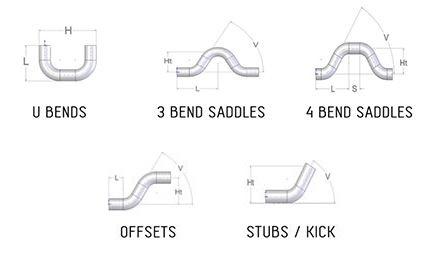

Offsets are two bends in opposite directions that allow the conduit to navigate around an obstruction, such as a beam, ductwork, or other structural elements. The offset creates a parallel shift, enabling the conduit to continue along the desired path without interfering with other structures. Accurate offset bends help maintain a streamlined layout and are commonly used in installations where precision is essential to avoid unnecessary strain on the conduit or fittings.

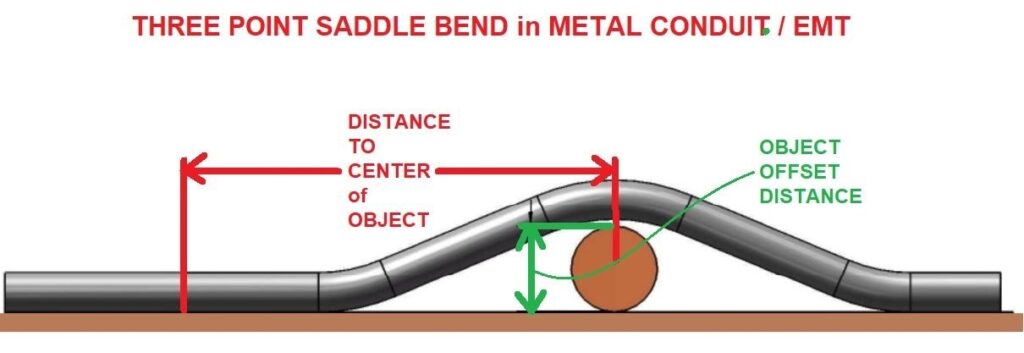

●Saddles

A saddle is a type of bending technique used to route conduit over a small obstacle, such as another pipe or conduit, while keeping the overall conduit run level. Saddles typically involve three bends: two smaller bends to rise over the obstruction and a middle bend to bring the conduit back in line. Properly executed saddles are essential in projects where conduit must cross obstacles without disrupting the system’s alignment or risking damage to surrounding structures.

●Back-to-Back Bends

Back-to-back bends consist of two 90-degree bends that create a U-shape, often used when a conduit needs to loop around a corner or make a sharp change in direction. These bends are crucial in layouts that require conduits to follow tight paths while staying within defined boundaries. Precision in back-to-back bending ensures that the conduit remains flush with surfaces, minimizes the risk of kinks, and supports a cleaner, more efficient installation.

4.2 Preparing for the Bend

●Marking the Conduit Correctly

Before starting a bend, marking the conduit accurately is crucial. The marks act as guides to ensure that bends occur at the exact points necessary for the conduit layout. Using a permanent marker or pencil is recommended, as these will provide clear, visible marks that won’t fade or rub off during handling.

Begin by identifying the exact points where each bend will start. A reliable way to do this is by measuring from a fixed reference point, such as the end of the conduit, to where the bend should begin. Making these markings with precision reduces the chance of errors, which can save both time and materials.

●Using Measuring Tools

Accurate measurements are the foundation of a successful bend. A tape measure is a straightforward yet effective tool for measuring conduit lengths precisely. After identifying the correct bend points, use the tape measure to mark these points on the conduit.

Take note of any additional measurements needed for specific bends, such as offsets or saddles, which may require multiple marks along the conduit. For added accuracy, double-check measurements before marking, and make sure the tape measure is taut and positioned properly to avoid slight errors.

4.3 Accounting for “Gain” and “Take-Up”

●Defining “Gain” and “Take-Up”

Take-Up is the amount of conduit length absorbed by the bending process. When making a 90° bend, the conduit shortens on one side as it bends, which can impact your measurements if not accounted for. Manufacturers often provide a take-up chart indicating how much length to subtract for specific angles and conduit sizes.

Gain refers to the added length of conduit that appears when a bend is made, primarily noticeable in 90° bends. Essentially, gain compensates for the fact that the outer edge of the bend stretches, adding length to the overall conduit.

●Common Values and Example Calculation

For example, when making a 90° bend, you might experience a take-up of around 5 inches for 3/4-inch EMT conduit. This means that if you want a 10-inch stub length (the vertical section after the bend), you should measure and mark the conduit at 15 inches, allowing for the 5-inch take-up.

Example Calculation:

Suppose you need a 20-inch stub length from the start of a 90° bend. If the conduit has a 5-inch take-up, you’d add this to your target length:

20 inches+5 inches=25 inches

Mark your bend starting point at 25 inches from the end to achieve the desired 20-inch stub.

4.4 Using Angle Indicators and Guides

Angle indicators and guides on conduit benders help achieve consistent and precise angles, which are essential for an organized and functional conduit system. These tools make it easier to replicate bends accurately, even in complex layouts.

●Using Degree Markers on the Bender

Most conduit benders have built-in degree markers that help guide bends at specific angles, such as 10°, 30°, 45°, and 90°. To use these markers, line up the bender with the conduit at the starting point of the bend. Then, apply steady pressure while watching the degree marker to ensure you reach the desired angle.

For example, to create a 45° offset bend, align the conduit with the 0° marker and bend it until it reaches the 45° mark. Using these degree indicators helps you repeat the same angle across multiple bends, which is particularly useful for bends that need to match or align precisely with others.

●Using Protractors or Digital Angle Finders for Extra Accuracy

For added precision, especially in projects requiring high accuracy, it’s beneficial to use an external tool like a protractor or digital angle finder. These tools provide an independent angle measurement and can help verify that the bender’s angle markers are aligned correctly, ensuring accuracy. Digital angle finders, in particular, offer a high degree of precision and are useful for confirming angles in custom or unusual bends.

4.5 Tips for Offset and Saddle Bends

4.5.1 Techniques for Offset Bends

An offset bend is commonly used when the conduit needs to rise or fall over a short distance, allowing it to bypass an obstacle. The two bends of an offset should be identical to ensure smooth transitions, and using the multiplier method can help achieve this.

Multiplier Method: To create an offset bend, first determine the distance you need to clear (offset height). Then, multiply this height by a specific factor (multiplier) based on the desired angle of the bend. Common multipliers include:

2.0 for a 30° bend

2.6 for a 22.5° bend

1.4 for a 45° bend

For example, if you need a 3-inch offset with 30° bends, multiply 3 inches by 2.0 (the multiplier for 30°), resulting in 6 inches. This means the distance between the two bends should be 6 inches to achieve the correct offset height.

Procedure: Mark the conduit where each bend will start, then use the bender to make the first bend to the specified angle. Measure the distance along the conduit and make the second bend in the opposite direction, ensuring it mirrors the first. This technique allows for quick and accurate offset bends.

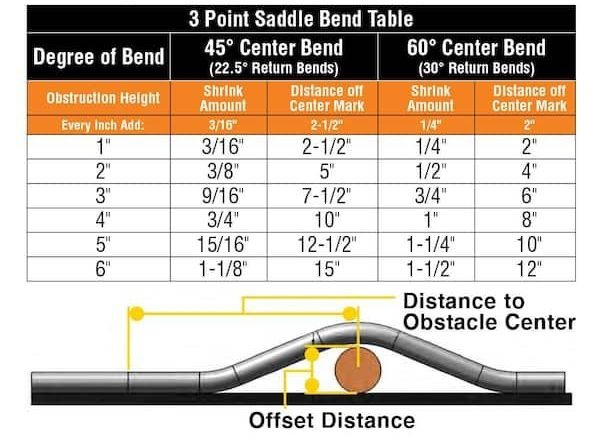

4.5.2 Techniques for Saddle Bends

Saddle bends are used to move the conduit over a specific obstacle (e.g., pipes or beams) while keeping it aligned with the layout on both sides of the obstacle. There are typically two main types of saddle bends: three-point saddles (for smaller obstacles) and four-point saddles (for larger obstacles).

Three-Point Saddle Bend: To create a three-point saddle, measure the height of the obstacle and mark three points on the conduit: one for the center bend and two for the outer bends.

Bend the conduit at the center mark to the angle needed to clear the obstacle, commonly 45°.

Make the two outer bends at half the center bend’s angle (usually 22.5°), ensuring they mirror each other to maintain alignment.

Four-Point Saddle Bend: Used for larger obstacles, this method requires four bends, with the first and last bends usually at 22.5° and the middle bends at 45°. This more complex setup ensures that the conduit remains flat after clearing the obstacle.

5. Tools and Accessories for Accurate Conduit Bending

Having the right tools and accessories can make conduit bending more efficient and precise. Here are some essential tools to consider for ensuring accuracy and consistency in your conduit bending projects:

5.1 Conduit Bending Calculator

A conduit bending calculator is a valuable tool for quickly determining the correct lengths and angles for different types of bends, such as offsets, saddles, and back-to-back bends. Calculators can be handheld or app-based and often include preset functions for common bending calculations, which makes them especially handy when working with multiple bends on the same conduit. By entering key measurements, you can get immediate guidance on where to mark and bend, reducing the risk of errors.

5.2 Angle Finder or Protractor

An angle finder or protractor helps ensure accurate angles, especially with manual benders where precision can vary. Digital angle finders are particularly helpful for achieving exact bends, as they display the angle measurement in real-time, ensuring you’re on target. For complex bending layouts or custom angles, an angle finder can be invaluable, allowing you to double-check bends before and during installation to confirm they’re consistent with your specifications.

5.3 Level or Square

A level (spirit or digital) or square is crucial for making sure that the conduit remains straight and aligned, particularly on horizontal runs. Using a level helps ensure that the conduit remains flat and doesn’t unintentionally tilt during installation, which is essential for both functionality and appearance. Squares are particularly helpful when bending multiple sections that need to connect seamlessly, as they can verify that your bends maintain the correct alignment relative to the other conduit sections.

5.4 Templates for Multiple Bends

When a project requires numerous identical bends, such as in large-scale installations, creating a template for those bends can save time and maintain uniformity. Templates are guides made from an initial correctly bent conduit and can be laid alongside other sections to ensure they match the original angles and lengths. This is particularly helpful for large projects where minor deviations can accumulate and affect the final layout. Templates are simple but highly effective tools for reducing variations across multiple conduits, ensuring a consistent, professional look and accurate alignment in the overall layout.

5.5 Conduit Connectors Help Turning Corner

In addition to bending the conduit itself to achieve a turn, the use of conduit fittings can provide a more efficient and less damaging solution. These fittings are designed specifically to make turns in the conduit system while minimizing the risk of damaging the conduit or the wiring inside. By utilizing fittings, installers can achieve smooth, controlled turns without stressing the conduit material, which is especially beneficial for protecting sensitive wiring.

●Elbow Connectors

Elbow connectors are designed to make smooth 90-degree turns in conduit systems. Available in various angles (usually 90° and 45°), they are perfect for directing conduits around corners and obstacles. They ensure that the conduit follows a gradual curve, reducing the risk of damage to both the conduit and the wiring inside.

●Sweeps Bends

For larger conduit sizes, a sweep provides a more gradual curve compared to a standard elbow, ensuring a smoother transition and reducing stress on the conduit.

●Tee and Cross Connectors

While not strictly used for turning corners, tee and cross connectors can be helpful when branching off a conduit run at an angle. These connectors enable multiple pathways for conduit to follow, which can include turns around corners.

●Flexible Conduit Options

For more complex or tight turns, flexible conduit allow for easy bending without compromising the conduit’s integrity. These conduits are commonly used in applications where fixed rigid connectors cannot be applied, such as in machinery or areas with moving parts.

6. Conclusion

In this post, we’ve explored the different types of conduit benders—manual, electric, hydraulic, and specialty benders—each suited for specific conduit sizes and materials. We’ve also covered essential bending techniques, such as measuring accurately, understanding gain and take-up, and using the right tools for consistent and precise bends.

Ctube is a manufacturer and supplier of high-quality PVC conduit and fittings, specializing in providing innovative, durable, and cost-effective solutions for electrical installations. Ctube offers a wide range of conduit options, including Schedule 40 conduit, Schedule 80 conduit, and specialized conduits such as DB120 and Type EB, designed for both residential and industrial applications.

At Ctube, we understand the importance of reliability, safety, and performance in electrical conduit systems. Our products are rigorously tested to ensure they meet stringent standards, including resistance to pressure, impact, and extreme temperatures, as well as UV and corrosion protection. Whether you’re working on an underground installation or an above-ground project, Ctube provides the right conduit and fittings to get the job done efficiently and safely.

FAQs

1. What is the difference between a conduit bender and a conduit connector?

A conduit bender is a tool used to bend the conduit itself to create angles and curves for directing electrical wiring. A conduit connector, on the other hand, is a fitting used to join two pieces of conduit or change the direction of conduit without bending the material.

2. Can I bend PVC conduit without a heated bender?

While it’s possible to bend PVC conduit manually without heat by using a PVC conduit bender, applying heat can help soften the material, allowing for smoother and more accurate bends. For tight or complex bends, it’s best to use a heated PVC bender to avoid cracking or kinking the material.

3. How to bend conduits in cold weather?

Bending conduit in cold weather can be challenging, especially for PVC and some metal conduits.

Warm the conduit: For PVC, use a heat source like a heat gun to warm the conduit before bending. This makes the material more flexible and reduces the risk of cracking.

Use slow, steady pressure: Avoid applying force too quickly, as it can cause the conduit to bend unevenly or break in cold conditions.

Store materials in a warm area: If possible, keep your conduit indoors or in a heated space until you’re ready to use it. This helps prevent the material from becoming too brittle.